This article details how spreadability testing is performed using a texture analyzer. This instrument is commonly used to take physical measurements because it is relatively affordable, straightforward to use and performs tests in relatively quick time — usually in less than one minute. In addition, different product types can be evaluated thanks to various fixtures used with the texture analyzer: lipstick cantilever, eye pencil holder, hair combability fixture, etc.

Log in to view the full article

This article details how spreadability testing is performed using a texture analyzer. This instrument is commonly used to take physical measurements because it is relatively affordable, straightforward to use and performs tests in relatively quick time — usually in less than one minute. In addition, different product types can be evaluated thanks to various fixtures used with the texture analyzer: lipstick cantilever, eye pencil holder, hair combability fixture, etc.

Human test panels play an essential role for evaluating the acceptability of new cosmetic formulations. While this use of human resources is an expensive approach, it improves the chances that consumers will try the newly launched products.

Before production begins, however, instrumentation to measure physical properties, such as the spreadability of a new skin cream, can quantify benchmark values for select performance features. Texture analyzers, for example, use spreadability test fixtures to measure how much force is needed when applying or rubbing lotion or cream onto a surface.

Thus, earlier testing by human panels establish limits for acceptable application force ranges. Then, instrumentation can easily verify that production batches satisfy this requirement.

Texture Analyzer Mechanics

To measure spreadability, a texture analyzer it utilized that incorporates a specialized spreadability test fixture. Here, a cone-shaped probe is attached to the analyzer that aligns with a cone-shaped receptacle on the base beneath the probe. This receptacle holds the sample.

The probe then moves downward at a defined speed to compress, e.g., the face cream to a set distance. As the probe moves into the sample holder, it measures the amount of force required to penetrate the surface of the cream.

The ease with which the conical probe moves downward into the cream translates into the product’s spreadability. Other parameters that can be measured with this test include the firmness of the cream or its adhesiveness; i.e., ability to stick to a surface.

Case Study: Moisturizing Cream

Moisturizing cream is perhaps the most common personal care product used for moisturizing, rejuvenating, toning, healing and preventing the signs of aging in skin. Facial creams are most often white or pale in color, based on a lotion product form and have a light, sometimes oil-free consistency. To demonstrate the texture analysis of this product form, cream samples were stored overnight at 21°C. A texture analyzer with specified load cell was then used to perform the compression test described.

Equipment: Equipment included the texture analyzer with 1,000-g load cell; base table to hold the spreadability test fixture sample container; the spreadability test fixture probe; and software to control the device and analyze the data.

Once the test starts, the prove moves downward into the sample, reaches a defined distance, then reverses direction and withdraws from the sample. In this case, compression was measured 12 mm deep into the sample, with a trigger force of 10 g to begin data collection; the probe moved at a 1 mm/s travel rate to and from the sample, and a 4 mm/s rate while compressing the sample.

Sample preparation: Using a putty knife, small amounts of the sample were scooped into the holder, carefully avoiding or popping any air bubbles formed, which can cause data discrepancies.

Spreadability Results

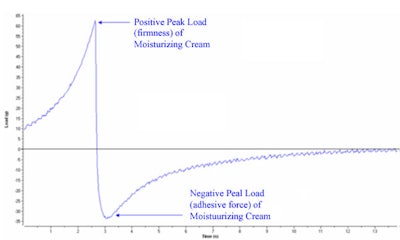

Figure 1 shows a typical data plot from the spreadability test. The x axis is time and the y axis is load force in grams. Once the probe makes contact with the test sample, the measured force climbs steadily until it reaches a peak value. The probe then reverses direction and withdraws from the sample. Here, the measured force is negative because the cream adheres to the probe, resisting its movement out of the sample container.

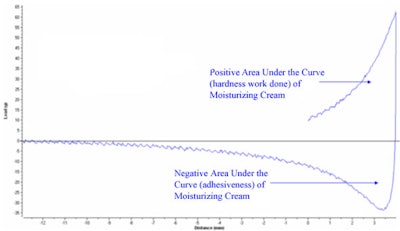

The same data plotted on a graph with the x axis showing the distance of the probe travel is shown in Figure 2. Data shown this way helps to calculate the work required to penetrate the sample. Integration of the area above the x axis and under the curve from the start of the test to peak force value is, by definition, the “hardness work done.” This is measured in scientific units of milliJoules.

The same data plotted on a graph with the x axis showing the distance of the probe travel is shown in Figure 2. Data shown this way helps to calculate the work required to penetrate the sample. Integration of the area above the x axis and under the curve from the start of the test to peak force value is, by definition, the “hardness work done.” This is measured in scientific units of milliJoules. The same approach is taken with the integration of the area between the x axis and the negative force curve to calculate “adhesiveness.” Both values are used to characterize the physical properties of each test sample.

The same approach is taken with the integration of the area between the x axis and the negative force curve to calculate “adhesiveness.” Both values are used to characterize the physical properties of each test sample.Discussion and Conclusions

As stated, the maximum force value is the peak load and is a measure of sample firmness. Thus, the higher the value, the firmer the sample. “Hardness Work Done” indicates the work required to physically move the cream during penetration. This translates into how well the sample will spread.

Adhesive force (stickiness) is the force needed to overcome the attractive forces between the cream still in contact with the probe during withdrawal from the sample. In other words, adhesiveness is the work required to pull the probe away from the cream.

Beyond skin care, as noted, additional fixtures enable measurements in, e.g., eye pencils, lipstick and hair combability. The test methods are similar to spreadability in that the compression test mode is used. Results also are similar with the exception that withdrawal of the probe from these samples is not relevant.

This demonstrates the various mechanical tests possible with one texture analyzer device and various fixtures. Such tests provide a practical QC approach for validating product physical properties before shipment to end users.