There is great interest from consumers for cosmetic products that have substantiated soft-focus claims; i.e., those that demonstrably blur the appearance of fine lines and wrinkles. This should be achieved without the formulation giving too much coverage, which can impart an unnatural appearance. One means to achieve this effect is via the use of an appropriate soft-focus powder.

What determines the appropriate powder? The present paper seeks to answer to this question using a new method to screen powders. The goal is to provide formulators with an additional tool to better ensure target performance.

The Perfect Powder

Guidelines for effective soft-focus powders were previously summarized by Emmert1 and include: minimal light absorption; high total—and mostly diffuse—transmission; minimal specular reflection; and high scattered reflection. Other parameters include particle size and refractive index.

Ideally, a new powder is screened for its performance potential prior to incorporation in a formula and consumer panel testing. If several powder candidates have been identified, other considerations such as oil absorption and cost are considered as well.

Repurposed Approach

Several methods have been described in the literature to evaluate powders for soft-focus potential.2-8 These vary in their optical measurements and instrumentation, and each offers advantages and disadvantages. A preferred method would be to use typical powder loading levels in a carrier and to perform evaluations using lab scale/benchtop equipment. The method proposed here instead uses realistic powder levels and a handheld, multi-angle spectrophotometer to measure reflectance spectra at various angles relative to the fixed illuminant. Further, the test powder is dispersed in a clear film that is prepared by drawdown on a synthetic leather substrate.

A handheld, multi-angle spectrophotometer is commonly used in the color evaluation of films or surfaces with effect pigments whereby the color changes upon observation angle. Analytically, this can be seen as changes in the shape of the measured reflectance spectrum with observation angle. This approach has not yet been used to evaluate the soft-focus performance of a cosmetic sample, since the color of a film with a soft-focus powder is not expected to change with differing observation angles.

Reflection Angles

How does it work? Consider a perfectly glossy, mirror-like surface. It would exhibit high reflectance, i.e., high reflected light intensity, mainly at angles equivalent or close to the specular or “mirror” angle (see Figure 1). This reflectance intensity would thus be lower at other observation angles. Conceptually, then, the comparison of the intensity of the reflectance spectra at different measurement angles would differ between this specular angle and other angles.

On the other hand, a nonglossy surface with good soft-focus characteristics would give less specular reflection and more scattered reflection; two of Emmert’s criteria for soft-focus potential. In this case, the intensity of the reflectance spectrum should therefore be similar at all the different measurement angles so that the curves obtained from different angles overlap. As such, a comparison of the reflectance spectra at various angles should indicate whether the observation angle has a strong effect, which can be correlated to a greater or lesser amount of specular reflection.

In this study, the measurement angle found to give a good indication of soft-focus performance was the “behind-the-gloss,” or trans, angle. This angle is opposite from the specular angle, compared with the illuminant (see Figure 1). For effect pigments, this angle has been shown to be an important part of color characterization; in fact, it is incorporated into ASTM standards.9 Note that cis and trans measurement angles yield different results.

Several commercial instruments can measure reflectance at a “behind the gloss” angle; the instrument used here is a portable spectrophotometera. The measurement angles relative to the illuminant and the angle designation nomenclature used are shown in Figure 1.

Materials and Methods

Substrate selection: In this work, drawdowns were prepared on an artificial leather substrate rather than glass plates or transparencies, which commonly are used. This substrate is more similar to skin and since it is textured, the soft-focus effects of the applied film can more easily be visualized. For the following measurements, the powder concentration used was 10%, which is close to a typical use level in formulations; similar results also were observed with a 5% loading.

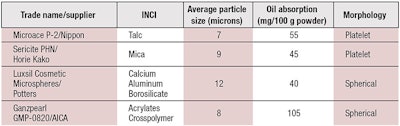

Powder materials: Four cosmetic grade powders were used in this study: jet-milled talcb, sericite micac, calcium aluminum borosilicate glass beadsd and a macroporous hydrophobic acrylates crosspolymere. Some physical characteristics are given in Table 1.

Two of these powders, talc and sericite, were used for comparison as they often are used as bulking agents in cosmetic powder formulations but are known to not improve soft-focus performance. The other two powders, calcium aluminum borosilicate glass and acrylates crosspolymer, have proven performance in both soft-focus10 and SPF-boosting capabilities.11 This SPF-boosting effect would be expected, since soft-focus performance acts via a similar mechanism of diffuse reflectance.

In addition to the instrumental analyses described, visual observations were used to confirm whether the incorporation of these powders in a cosmetic formulation could blur fine lines and wrinkles.

Comparing reflectance spectra at various angles reveals whether observation angles matter, which can be correlated to reflection and/or scattering abilities.

Carrier and substrates: The carrier used in this work was a commercially available, water-based finish that gives a high-gloss, highly transparent filmf. This transparency is important because the goal is to choose a powder that causes blurring but does not impart coverage to skin. Further, if the carrier were opaque, it would be difficult to discern whether the powder is covering rather than blurring. Similarly, if the film is matte, it would be difficult to evaluate the contribution of the powder.

This carrier was chosen rather than nail lacquer, which has been used in many of the previously studies cited in the literature. The water-based carrier additionally avoids the flammability and odor hazards associated with lacquer. For some evaluations, a blend of hydrocarbons was used as the carrier, for comparison purposes.

Since the refractive index of the water-based film was not available from the manufacturer, it was measured using a refractometerg and found to be between 1.506 and 1.516; similar to the refractive indices of the powders used in this work.

The drawdown substrates used were different shades of faux leatherh. This material is a urethane-based thermoplastic elastomer with polyester and cotton, and is lightly textured with a matte finish. The substrate was chosen since its gloss and texture are closer to that of human skin, compared with substrates used in other soft-focus literature studies, such as rigid glass plates, high-gloss drawdown cards or transparencies. The shades used were Camel (941), a lighter brown; Mojave (954), a darker brown; and Tuscon (933), a red. Multiple shades were examined to evaluate the applicability of the proposed characterization method on different substrate colors.

Test Protocol

Dispersions of 10% powder in the commercial carrierf were prepared using a stir bar. Drawdowns were prepared using a 10 mm drawdown bar and allowed to dry overnight before measurements were taken. The resulting films were transparent.

Additional dispersions of 15% powder were prepared in a hydrocarbon blend, for comparison. The hydrocarbon blend consisted of 18% polyisobutene and 82% isododecane; the refractive index of the blend was 1.434; as such, the films were not transparent due to their differing refractive indices. Reflectance spectra were measured using the aforementioned spectrophotometera equipped with softwarej. Four readings were taken for each sample, and the average result was used.

Results: Untreated Substrates

The reflectance spectra for the three different colors of faux leather substrate, untreated, at different measurement angles, are shown in Figure 2. As expected, the spectra overlap fairly well, as no color change was expected with changes in angle and the surface is matte. The exception was the 45as-15 angle, also known as the “behind the gloss” angle. This measurement location is in the trans position described above; as noted, this measurement angle has been identified as useful in the analysis of coatings with effect pigments.9, 12, 13

Results: Carrier and Carrier + Powder

After the highly glossy carrier film without powder was applied, the reflectance intensity was found to be greater at angles closer to the specular angle, as expected (see Figure 3). In the case of drawdown films with powder, measurements were conducted on all three substrates with films containing 10% and 5% powders. The observed results were similar for all substrates at both loading levels; for simplicity, only the results of the red substrate with 10% powder samples are shown. An overlay of spectra collected at the 45as110 angle is given in Figure 4. At this measurement angle, the reflectance spectra overlapped well for all the samples evaluated. Thus, the effect of powder addition on the intensity of light reflection was similar for the four powders evaluated, and the results do not distinguish between a “good” or a “poor” soft-focus powder.

In comparison, an overlay of the reflectance spectra at the 45as-15 angle showed differentiation between the powders, indicating different performance (see Figure 5). Since each powder can slightly change the film’s color and thus reflectance intensity, the powders are better compared by taking the ratio of the reflectance at 45as-15 and 45as110 angles, as shown graphically in Figure 6. This approach of self-referencing within a sample to eliminate the effect of filler on measured optical property values has previously been proposed2 for use with L* values. For all substrates tested and both powder loading levels, this reflectance ratio curve was higher for powders known to not impart soft-focus effects, such as talc or mica. The reflectance ratio curve becomes lower as the powder’s soft-focus performance improves.

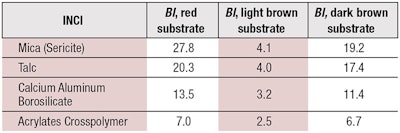

The maximum point of the reflectance ratio curve can be called the blurring index, BI, and used to compare the different powders. The values for BI, for the different color substrates evaluated in this study, are given in Table 2. Although the value depends on the color of the substrate, the same ranking is given for the four powders evaluated, regardless of substrate. To further evaluate the robustness of this method, films of different thicknesses were evaluated, and the additional rankings were obtained (results not shown).

The goal is to choose a powder that causes blurring but does not impart coverage to the skin.

The refractive index of a powder also is known to affect its transparency in a formulation. Since the refractive index of cosmetic carriers varies, it is of interest to evaluate this test method with a carrier of a different refractive index. As such, these same four powders were evaluated when dispersed in a blend of hydrocarbons rather than the aqueous carrier, and similar rankings were obtained (results not shown).

Summary

A new evaluation method is described here for the evaluation of powders for their soft-focus potential. Four powders are compared; two negative controls, known to not impart soft-focus benefits, and two recognized to be good soft-focus powders. In this method, drawdowns were prepared on synthetic leather substrates and the optical performance was characterized using a multi-angle spectrophotometer.

The powder performance, when evaluated in drawdowns in the same carrier on the same color substrate, could be ranked using a blurring index, BI. This ratio is defined as the intensity of the spectrum measured at the 45as-15 angle, relative to the 45as110 angle. While the value of the BI changes with the color of the substrate, the ranking was unchanged for different color substrates, and for carriers of different refractive indices.

Acknowledgments: The author would like to acknowledge David Albrecht, of DCD Technologies; X-Rite for the opportunity to evaluate use of the MA-98 instrument for the development of this soft-focus method; and Tim Mouwe (X-Rite) for useful discussions. In addition, Marie Yednak-Carpenter is to be acknowledged for her work on the hydrocarbon drawdowns used in this work.

References

- R Emmert, Quantification of the soft-focus effect, Cosm & Toil 111(7) 57–61 (1996)

- M Becker, C Schmidt, V Hochstein and X Petsitis, Measuring and pre-selecting functional filler pigments, Cosm & Toil 127(5) 390-396 (2012)

- LM Cukrov, JS Robinson, B Innes and PG McCormick, Measuring soft-focus properties of cosmetic filler particles, Happi (Aug 2003)

- J Leist, R Rojas-Wahl and M Sinha, Soft focus—A tool for advanced skin care formulation, SÖFW Journal 139(3) 1-10 (2013)

- W Benjamin Rogers, M Corbett, S Magkiriadou, P Guarillof and VN Manoharan, Breaking trade-offs between translucency and diffusion in particle-doped films, Opt Mater Express 4(12) 2621-2631 (2014)

- Momentive.com/products/literature/Optical-Effects-of-Particles/ (Accessed May 7, 2018)

- https://consumer.dow.com/en-us/document-viewer.html?ramdomVar=8266884836033087099&docPath=/content/dam/dcc/documents/en-us/catalog-selguide/27/27-15/27-1560-01-dowsil-specialty-silicones-for-soft-focus.pdf (Accessed Oct 31, 2018)

- http://koboproductsinc.com/Downloads/KoboBlur-Complexes-for-SoftFocus-Effect.pdf (Accessed Oct 31, 2018)

- astm.org/Standards/E2194.htm (Accessed Oct 15, 2018)

- US Pat Application 62/480,884, Method of determining optimal powder and formulations for wrinkle blurring compositions, Z Szabados, D Benderly, M Yednak-Carpenter and K Kannheiser, assigned to Presperse Corp (Apr 3, 2017)

- SPF boosting powders, FL SCC Poster Session (2013 Sunscreen Symposium)

- WR Cramer, Reflections on the right angle, Euro Coatings J 4 32-37 (2012)

- E Kirchner and W Cramer, Making sense of measurement geometries for multi-angle spectrophotometers, Col Res Appl 37 186-198 (2012)

!['We believe [Byome Derma] will redefine how products are tested, recommended and marketed, moving the industry away from intuition or influence, toward evidence-based personalization.' Pictured: Byome Labs Team](https://img.cosmeticsandtoiletries.com/mindful/allured/workspaces/default/uploads/2025/08/byome-labs-group-photo.AKivj2669s.jpg?auto=format%2Ccompress&crop=focalpoint&fit=crop&fp-x=0.49&fp-y=0.5&fp-z=1&h=191&q=70&w=340)