Welcome back to a continuing discussion regarding the new Registration, Evaluation and Authorization of Chemicals (REACH) regulation and its impact on chemical testing. As discussed in the previous column,1 regulation No. 1907/2006, or REACH, is in effect in the European Union (EU) and safety information must now be provided on all chemicals that are either sold, manufactured or imported into the EU in a quantity greater than or equal to one ton per year.

Current estimates indicate that the REACH regulations will apply to more than 30,000 existing chemicals, and the effort to screen all of the materials could result in the deaths of several million animals if animal testing alone were used in the screening process.2

To avoid the use of such a large number of animals, the REACH regulation has mandated that in vitro alternatives be used to replace animal testing whenever possible. While the list of currently validated in vitro alternative methods is alarmingly short, there are many new methods in the process of validation that could be introduced in the very near future. It is the purpose of this series of articles to provide an overview of these existing validated in vitro methods, as well as new methods that are being considered for validation.

Reviewing Alternative Methods for Corrosion Testing

As mentioned, this is the second column in a series discussing in vitro testing alternatives; the first column discussed alternatives to replace the Draize rabbit test to assess skin corrosion potential. The in vitro alternatives described were based on human skin tissue equivalentsa,b that were grown in culture and that met the Organization for Economic Co-Operation and Development (OECD) guidelines for an acceptable in vitro epidermal model.3

Briefly, the guidelines for an epidermal model to screen materials for corrosion potential stated the following:

• The model should be constructed of human keratinocytes that have been cultured to form a three-dimensional structure similar to human skin;

• The model should have a functional stratum corneum (SC);

• The barrier function should be similar to human skin; and

• The model should be grown in a manner where materials that are applied topically can only access the viable lower layers of the tissues by penetrating through the SC and not flowing around the edges of the epidermal model.

Functionally, the epidermal models should be sufficiently sensitive to distinguish between materials of differing corrosive potential.

These same guidelines can be applied to in vitro alternatives to screen materials for irritation potential because skin corrosion and skin irritation are similar in that they both involve damage to the epidermal layer of the skin.

Draize Rabbit Skin to Test Skin Irritation

Both skin corrosion and skin irritation potential testing have traditionally been performed using the Draize rabbit skin test.4 Materials are applied topically to the shaved skin of an albino rabbit and the skin response is graded at various time intervals. If the material causes irreversible skin lesions that penetrate into the dermis after less than four hours of exposure, the material is classified as corrosive. If the material does not produce deep lesions but instead produces erythema and edema at the site of application, it is classified as an irritant.

The degree of irritation could be subjectively graded with this model, ranging from a slight to severe irritant, based on the degree of erythema and edemaagain, ranging from slight to severe for both measures.

While this method has been used for more than 50 years, it has long been challenged regarding how accurately it predicts irritation for human skin.5

Using Skin Models to Test Skin Irritation

As an alternative to the Draize rabbit test, two commercial skin models have been validated for skin irritation testinga,b.

Application of test materials: The basic protocols for both models involve the topical application of test materials to the surface of the tissues, culturing the tissues for various time intervals, and then assessing tissue viability at each of the intervals.

Although the general irritation protocol is similar to the in vitro method for corrosive potential testing, it differs in the duration of test material application. Corrosive materials can rapidly damage the epidermal layer of the skin. Therefore, corrosive potential testing is typically performed using two applications of the test material—one for 3 min and another for 1 hr. In contrast, material application for irritation testing can range from less than 1 hr, if the material is believed to be severely irritating, to more than 24 hr if the material is believed to be very mildly irritating or a nonirritant.

Since corrosive materials can rapidly damage the epidermal layer of the skin, typically just a 3-min and 1-hr application of the test material is used for corrosive potential testing. The corrosive testing protocol was detailed in the previous article.1

Assessing tissue viability: Once the material application is complete, tissue viability needs to be determined at each time point used in the study. Tissue viability can be determined using an MTT (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) assay, in which the mitochondria of viable cells will reduce the MTT into purple formazan crystals that are insoluble in aqueous solutions and will remain trapped in the tissues. The purple formazan crystals can be extracted from the tissues using isopropyl alcohol and quantified spectrophotometrically. This spectrophotometric measurement can be used as an index to determine tissue viability.

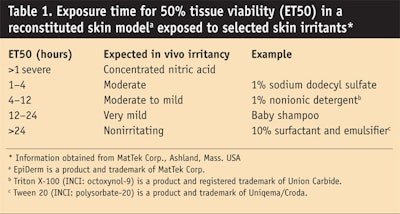

Once the average tissue viability is determined at each time point, a graph can be generated by plotting mean tissue viability versus exposure time for each test material. Once the relationship between tissue viability and exposure time is known, then the time point at which tissue viability is reduced by half (50% tissue viability) can be predicted. This time point is referred to as the ET50 or exposure time for 50% viability, and can be used to determine the irritation potential of the test material. For example, MatTek has established the data in

!['We believe [Byome Derma] will redefine how products are tested, recommended and marketed, moving the industry away from intuition or influence, toward evidence-based personalization.' Pictured: Byome Labs Team](https://img.cosmeticsandtoiletries.com/mindful/allured/workspaces/default/uploads/2025/08/byome-labs-group-photo.AKivj2669s.jpg?auto=format%2Ccompress&crop=focalpoint&fit=crop&fp-x=0.49&fp-y=0.5&fp-z=1&h=191&q=70&w=340)