Today’s sunscreens must prove, more than ever, their efficiency and safety since, among all other products, they are the object of crucial health-related regulations. Sunscreen product companies must therefore give consumers a reliable sun protection factor (SPF). To determine SPF, an in vivo test should be used (per ISO 24444)—i.e., creams tested on the backs of volunteers.1 However, such tests present several inconveniences, including cost and ethical concerns. For all these reasons, companies and the European Commission turned toward the development of in vitro methods.

The most common in vitro method consists of applying the cream to polymethylmetacrylate (PMMA) plates, forming a thin layer. UV radiation attenuation is then determined by passing radiation through the cream and measuring the transmission spectra by spectroscopy. The results are then converted into a protection factor mathematically.2, 3 The problem arises in persistent differences between in vivo and in vitro results, as well as reproducibility difficulties inter- and intra-laboratories.4, 5 Aberrations also are noted according to the nature of the cream and spreading procedure.

Numerous studies have been carried out on the effects of the roughness of the plate,6 the plate surface temperature7 and the technique by which the sample is spread.8, 9 These show that roughness control enhances the correlation between in vitro/in vivo results and limits their variation rate.10 The physics and properties of chemical surfaces and interfaces are engendered by parameters such as the substrate roughness, morphology and precise structure form or its constitution.

Connected with the problem of different cream behaviors on the plates, it is conceivable that surface properties are the origin of measurement difficulties. Therefore, an in-depth study of PMMA substrates was carried out to characterize each type of plate. Analyses were performed to highlight surface phenomena and their consequences on the SPF in vitro measurement.

Outlined here are surface characterizations of the substrates by Fourier Transform Infrared (FTIR) Spectroscopy, goniometry, profilometry and zeta potential techniques, both initially and at the SPF measurement, using different creams and protocols. The results suggest an ideal in vitro test substrate does not exist. Future in vitro SPF methods should therefore be based on two types of plates.

Materials and Methods

Plates: Numerous PMMA plate models have been proposed for in vitro measurements. They generally differ by average roughness and manufacturing process. Seven types are characterized in this study, including: three molded with a roughness of 2 μm (HD2)a, 5 μm (HD6)b and 12 μm (JCIA)c; and two each (four total) with a roughness of 2 μm and 5 μm, sandblasted by water (WW2, WW5)d or air (Europlast)e. In addition, HD6 plates pre-treated by the surfactant cocamidopropyl betaine (CAPB) were used.11 Ten plates for each type were tested.

Plate characterization, FTIR: Infrared (IR) measurements were performed within the Surfaces and Interfaces group of the University of Sciences of Nice Sophia Antipolis, with a spectrophotometerf equipped with an attenuated total reflectance (ATR) device. All the plates were tested to compare their IR spectra.

Plate morphology analysis: Non-contact, surface topographic analyses were conducted internally using a work stationg. The parameters analyzed were those of the control chart established in a previous study.10 The following ten parameters were used to control each batch of PMMA plates (molded or sandblasted):

- Ra, Sa: Average roughness

- Rp: Maximum height of peaks

- Rv: Maximum valley depth

- Rsk: Skewness

- Rdq: Root Mean Square Gradient

- Rku: Kurtosis

- A1: Equivalent Triangle Area for peaks

- A2: Equivalent Triangle Area for pits

- Ssc: Mean Summit Curvature

- Vvv: Volume of void in the valleys

For every plate, the measurements were carried out on five, 10 mm x 5 mm areas. All substrates were tested.

Goniometry: A goniometerh was used at the University of Sciences of Nice Sophia Antipolis. All measurements with pure water (ν = 0.072 N/m) were performed with a 2-μL drop. The contact angle was measured 10 sec after depositing the drop. Nine drops were placed on each plate. As plates have a roughness on the order of micrometers, researchers were interested only in the value of the contact angle and not the surface energy, which is more adapted to smooth surfaces.

In order to maximize the information collected, three methods were used:

Method I: Deposit pure water on the untreated plate. This examines the hydrophilic character of the raw plates.

Method II: Deposit pure water on plates pretreated by a surfactant; this method has been shown internally to improve in vitro/in vivo correlation.

Method III: Deposit diiodomethane on untreated and pretreated plates, in order to study the lipophilic character of the substrate and the treatment influence.

Zeta potential: A zetameterj from the University of Sciences of Nice Sophia Antipolis measured the zeta potential for each type of plate every 0.3 pH unit, from 3.5 to 9.5. The electrolyte used was a potassium chloride (KCl) solution at 10-3 mol/L. Moreover, in order to vary the concentration, the device was equipped with hydrochloric acid (HCl) and sodium hydroxide (NaOH) at 10-1 mol/L.

The plates with greater roughness encountered difficulties during the cell assembly because this method is more adapted to smooth surfaces. These problems can be surmounted, however, either by using poly(terephthalate ethylene) (PET) layers, which hold the sample more strongly; or by modifying the program parameters, i.e., increasing the rising time or decreasing the pH steps. JCIA plates having a roughness of 12 µm still caused difficulty, so less data was collected.

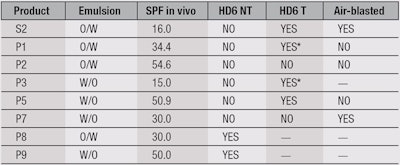

SPF measurements: For SPF measurements, eight creams were studied; four w/o and four o/w. In addition, to take into account the potential influence of SPF value, two SPF 15, three SPF 30 and three SPF 50 samples were chosen according to their good or bad correlation SPF in vivo/in vitro. Internal results, obtained using the 5 μm roughness of: the molded PMMA platesb pretreated with cocamidopropyl betaine (“HD6 T”), untreated molded PMMAb plates (“HD6 NT”), and the air-blasted plates, allowed for the selection of a panel of diversified creams—i.e., where at least two gave good results on each of these supports.

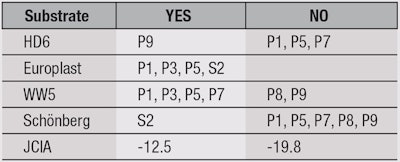

Table 1 summarizes the main characteristics of the chosen formulas. A result was “good” when the difference between the in vivo and in vitro SPF value was lower than or equal to 25%. It was considered “bad” if the difference was greater than 50%. Further, “YES” indicated good results and “NO,” bad ones. “YES” followed by an asterisk (*) specified the difference was lower than 50% but higher than 25%.

The composition of each cream also was studied: UV filters, surfactants and other common raw materials were listed, to consider any possible influences on the measurements. Products were spread onto substrates by an experiment operator. The initial amounts used correlated with those established following previous studies.10, 11 The method consisted of applying 1.3 mg/cm² of cream onto the HD6, WW5 and Europlast plates; 0.75 mg/cm² on the Schönberg, WW2 and HD2 plates; and 2 mg/cm² on the JCIA.

Furthermore, a fingercot was required for JCIA application. The SPF was calculated on nine areas of each plate. Moreover, the plated were weighed before the addition of the product, then before the measurement in order to know the quantity during manipulation. For SPF measurements, a transmittance analyzerk was used. SPF measurements were performed on all the supports except the WW2 and HD2, due to a lack of plates.

Results: FTIR

The plate spectrums (see Figure 1) showed the same peaks for all support types. The surfaces had the same functional groups, as evidence by carbon group peaks at 850-700 cm-1 and 3000-2950 cm-1; the ester carbonyl at 1720 cm-1; and two peaks at 1235 cm-1 and 1145 cm-1 for the C-O. These spectra are in agreement with the well-known PMMA structure shown in Figure 2. Thus, the FTIR analysis did not discriminate between supports.

Results: Profilometry

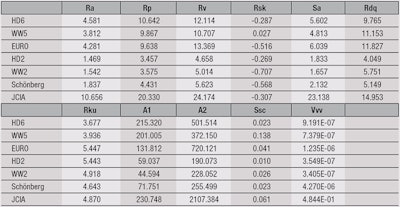

Profilometry was used to examine several morphological parameters, with the aim of differentiating plate types. The results shown in Table 2 are the averages of the five areas measured on each plate, using ten plates per type.

To determinate factors differentiating the plates, a discriminant analysis was performed on the data. Due to the strong correlation between parameters, the Partial Least Square–Discriminant Analysis (PLS-DA) was preferred to a classic discriminant analysis. The calculations were run through software analysism.

Table 3 shows the relative importance of the morphological parameters for every plate. For each plate type within a column, the first number is the regression coefficient of this plate type. A positive value indicates the parameter is higher than the parameter average; a negative one is lower. For example, the highest value above average for Europlast was for A2 (equivalent triangle area for pits); the lowest below average was for Rsk (skewness). The most important is the absolute value whereas the most discriminant and relevant is the parameter. JCIA were eliminated from this study since the values were very different from the others.

The second number, shown in brackets, expresses the percentage of contribution in the discrimination profile. Here, Europlast was mainly characterized by Rsk, A2 and A1 (equivalent triangle area for peaks). Note that for each parameter, its contribution to plate type discrimination could be investigated—here, SSC (mean summit curvature) appears relevant for all the plate types, followed by Rdq (root mean square gradient). In contrast, Ra (average roughness), Rv (maximum valley depth) and Rku (kurtosis) had poor power of discrimination.

Results indicated that molded and sandblasted plates could be differentiated by their Ssc (mean summit curvature), which was higher for the sandblasted, and Sa (average roughness), which was higher for the molded plates. They differed in slopes (Rdq) and curvatures (Ssc), which were higher for the Europlast. These plates were similar at the level of Vvv (volume of void in the valleys), however.

Although both sanded, plates sanded by air and by water differed significantly at the level of the parameters Rsk and A2. Figure 3 represents the contribution of the parameters studied for each substrate type. This clearly shows the difference obtained for the Ssc between sandblasted (in red) and molded plates (in blue).

Results: Goniometry

Surface wettability is an essential parameter in the interface phenomena. Therefore, all substrates were assessed via various methods.

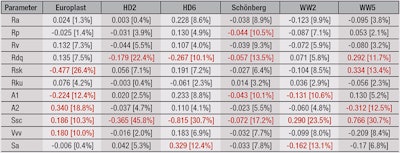

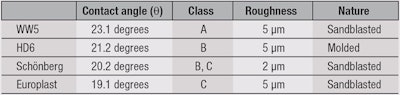

Method I, no pretreatment: Table 4 shows a comparison of average data levels followed by a Tukey-Kramer test. The aim was to classify plates by grouping those that were significantly different. In this case, five classes were apparent at p < 0.05. The WW2 were the least hydrophilic; the Schönberg, the most. Among those having greater average roughness, the Europlast plates were the least hydrophilic. The WW5, HD6 and HD2 plates make up a median class, referred to as Class C; the JCIA plates were the second most hydrophilic (see Table 4). All the plates were noticeably hydrophilic at a contact angle greater than 90 degrees.

For median class C in particular, the wettability was similar for substrates of the same roughness but made via different processes; HD6 and WW5, for example. Wettability was also similar in cases of substrates having different roughnesses but made via the same process, as in the case of HD6 and HD2. In contrast, wettability was different for substrates having the same roughness and made via the same process; i.e., Europlast, WW5 or WW2, and Schönberg. These results demonstrate that surface wettability is independent of the roughness and nature of the plate, i.e., sandblasted or molded.

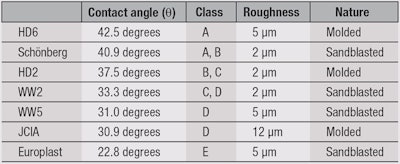

Method II, pretreatment with CAPB: As has previously been shown, a surfactant can be used to pretreat plates for SPF measurements to improve the affinity of the cream to the surface.11 The impact of the surfactant on wettability was tested in this step; Table 5 shows the average contact angles obtained.

The presence of the surfactant reduced the contact angle and increased the hydrophilic character of the substrate. Three classes were observed, which again were independent of the roughness and the substrate process.

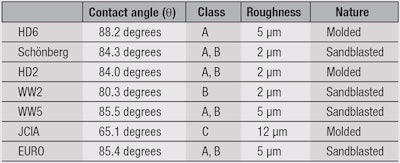

Method III, diiodomethane with and without CAPB: Regarding lipophilicity, a variance of analysis on the results of diiodomethane, applied to substrates with and without CAPB, revealed five classes (see Table 6). The Europlast were the most lipophilic plates and the HD6 (closest to the Schönberg) were the least.

The difference between WW2 and WW5, i.e., created by the same process but with different roughnesses, was approximately 2.3 degrees. The difference between the Schönberg and Europlast was 18 degrees—also created by the same process and having different roughnesses. The sandblasted plates with the lowest roughness had the largest lipophilic value. This comment is reversed for the molded plates because the HD2 are more lipophilic than the HD6, with a difference of 5 degrees. The authors concluded that lipophilic character was independent of the roughness or manufacturing process (molded or sandblasted).

As shown in Table 7, the use of surfactant decreased the variation of wettability between the different types of plates—except JCIA, but strong roughness can cause surfactant spreading. So, by definition, the plates were all hydrophilic in nature and exhibited strong lipophilic character. The surfactant completely modified the surface of the plates and did not allow for their differentiation.

Results: Zeta Potential

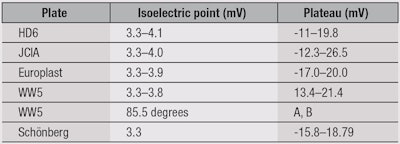

This method is used to obtain information about the surface charge of plates. Figure 4 shows all the results and Table 8 summarizes the values. The purpose of this measurement was to compare values adopted by the different substrates. The most remarkable were the isoelectric point, i.e., zeta potential where pH is equal to zero; and the plateau (in some cases). In the present study, the isoelectric values were not distinguishable per substrate type and for those between 3.3 and 4 mV. In addition, the plates could not be differentiated by the values adopted by the plateau.

These types of curves are characteristic of amphoteric surfaces, i.e., positive and then negative values as the pH levels increase. With all the curves being indistinguishable, the authors concluded the charges on different substrate types were relatively similar and the surface charges were not influenced by the nature of the plate (molded or sandblasted) or roughness.

Summary of Plate Findings

Taken together, the described analyses allowed for the characterization of various substrate types.

While the functional groups and charges were the same for all types, goniometry and profilometry introduced some discriminating parameters. The contact angle with pure water, for example, highlighted five groups within the seven types of plates. Interestingly, the nature of the plate—i.e., sandblasted or molded; or low or high roughness—did not form groups.

The Ssc (mean summit curvature) and Vvv (volume of void in the valleys) were relevant to discriminate plates, and the Rdq (root mean square gradient) and Ssc enabled the differentiation of molded and sandblasted plates. With the plates characterized, in vitro measurements were taken next to determine whether correlations could be made between the surface characteristics of the plates and the SPF in vitro values.

Results: SPF Estimates

Since SPF performance is related to the correlation between in vivo and in vitro SPF values, differences between the two were studied. In vivo results were taken from the normalized in vivo SPF tests (ISO 24444) of 10 volunteers. The average difference was considered according to the type of emulsion (see Table 9). The SPFs of w/o emulsions were, on average, underestimated using HD6, JCIA and Schönberg plates. O/W emulsions also were underestimated using HD6 and JCIA plates. Table 10 highlights the products leading to “good” or “bad” results, as indicated with “YES” or “NO,” in the same way as Table 1.

Surface Morphology

The present work demonstrates that each type of plate has its own characteristics and there are no interactions between functional groups, roughness, the nature of the plates, wettability or surface plate charges. The next step was to determine whether a common morphological parameter led to the same results for a product. This was accomplished by referencing Table 3 and Table 10; specifically the Rdq, Ssc and Sa parameters, per previous profilometry findings.

As was observed, plates could be differentiated based on their Rdq, Ssc and Rdq values, specific to their molded or sandblasted nature. Unfortunately, inconsistencies were found, for example in products P1 and P5, which gave a bad in vivo/in vitro correlation on the Schönberg plates, but a good one on the Europlast and WW5 plates; all three of which are sandblasted. At the same time, products P1 and P5 gave a bad correlation on the sandblasted Schönberg plate and the molded HD6 plate.

Conclusions were similar for the other data; i.e., no results could validate a morphological parameter as influencing the variations in SPF results. In the end, it seemed that some creams were influenced by morphological parameter whereas others were not.

Surface Wettability

The same observations were found for the study of hydrophilic/lipophilic plate characteristics and their influence on SPF measurements. While product P8 gave favorable results on HD6T plates, it did not on the WW5 or Schönberg plates. And while hypotheses could be drawn, they are refuted when examining results for products P9, P1 and P5. P1 gives favorable results on HD6T, Europlast and WW5 plates; and HD6T plates have very different wettability from Europlast plates.

Furthermore, P9 and P7 had different behaviors on HD6NT and WW5 plates, while the wettability of the two plate types is comparable. These observations led to the conclusion that SPF results are not directly connected to surfaces properties. Moreover, in cases where products gave poor results without a surfactant, the addition of CAPB gave good results. And in cases where products gave good results without a surfactant, the addition of CAPB maintained those results.

Product Composition vs. Measurement Effectiveness

After studying the tested formulae, no raw material was found to be capable of influencing measurements. In addition, neither the plate wettability nor the plate morphology directly influences the in vitro SPF measurements—only the average roughness, Sa, is known to impact plate measurements. It seems that the dependence of one parameter on any measurement is specific to the product itself. Thus, the in vitro SPF measurement should be product-dependent.

Conclusion

The determination of in vitro SPF consists in converting, mathematically, the UV absorbance of a sunscreen spread onto a PMMA substrate. The method still presents difficulties today. Too many results are variable or poorly correlate with in vivo values. Previous studies have proven that numerous parameters could be influencing SPF: the method of spreading, product composition, and substrate manufacturing process and roughness. Adhesion difficulties especially come up with in vitro SPF measurements, which shows the importance of understanding interface phenomena between the product and PMMA surface. To this aim, the present report begins by studying the different plates used.

In the described measurements, various plates could be differentiated by slope or peaks curvature morphological parameters. Wettability measurements showed that every plate has a specific surface tension, and this property alone does not allow for the differentiation between sandblasted and molded plates, or high and low average roughnesses.

Furthermore, measurements on surfactant-pretreated plates showed the contact angle value harmonized around 20 degrees with pure water, and 80 degrees with diiodomethane. By characterizing each plate, it was possible to study the relationship between their properties and the in vitro SPF results they produced.

Finally, in seeking a correlation between measurement efficiency and plate surface properties, these researchers observed that the influence of one parameter is specific to a given product. Some products are sensitive to hard slope and curvature, while others are not. To find a type of cream that is sensitive to one parameter has not been possible because it depends neither on the emulsion nature, nor the SPF value, nor the UV filter or emulsifying composition.

This study provided key insight into the future of in vitro SPF test methods—namely they must not be based on one specific test plate type, but preferably on two specific test plate types, as described elsewhere,12 since this study clearly shows the ideal substrate does not exist.

References

- ISO 24 444:2010

- BL Diffey and J Robson, J Soc Cosmet Chem 40 127–133 (1989)

- M Pissavini et al, Cosm & Toil 118(10) (Oct 2003)

- M Rohr et al, Skin Pharmacol Physiol 23 201-2012 (2010)

- N Lionetti, C Cartigliani, A Bonfigli and L Rigano, Personal Care 27-31 (2014)

- L Ferrero, M Pissavini, A Dehais, S Marguerie and L Zastrow, IFSCC magazine 9(2) (April/Jun 2006)

- S Miksa, D Lutz and C Guy, Cosm & Toil 128(7) 484-494 (Jul 2013)

- L Fageon, D Moyal, J Coutet and D Candau, Intl J Cosm Sci 1-13 (2009)

- S Miksa, D Lutz and C Guy, Cosm & Toil 128(10) 742-752 (Oct 2013)

- M Pissavini, S Marguerie, A Dehais, L Ferrero and L Zastrow, Cosm & Toil 124 (2009)

- S Marguerie, M Pissavini, A Baud, T Carayol and O Doucet, J Cosmet Sci 63 243-254 (Jul/Aug 2012)

- S Miksa, D Lutz and C Guy, Intl J Cos Sci (2015)

!['[Sunscreen] developers will be able to innovate more efficiently while maintaining high standards of quality and safety for consumers.'](https://img.cosmeticsandtoiletries.com/files/base/allured/all/image/2024/06/woman_outside_using_sunscreen_on_face_ISO_test_standards_AdobeStock_783608310.66678a92029d9.png?auto=format%2Ccompress&fit=crop&h=191&q=70&rect=62%2C0%2C2135%2C1200&w=340)