Improved combing, softness, shine and suppleness are but a few examples of the properties silicones have long provided in hair care. More recently, their benefits have expanded to include fast-drying effects, reduced frizz, color protection and hair repair. As is well-known, an emerging application of silicones has been to help protect hair from damage associated with heat styling; e.g., from tools including hair dryers, curling irons or straightening plates.1 Appliances of this type can reach temperatures as high as 230°C (446°F), which denatures keratin and causes hair damage.2 Today’s consumers are increasingly conscious of these issues and therefore seek heat protection solutions for hair.

Consumers view heat styling differently. Some use heat appliances more often or at higher temperatures than what’s recommended. Others are careful not to over-use heat appliances or excessive temperatures. Still others avoid any form of heat treatment.3 Using test methods to emulate consumer habits, researchers examined the ability of silicones to protect hair during heat styling and compared them with other industry benchmarks and untreated hair, described here. Also discussed are the mechanisms through which different silicones contribute heat protection.

Test Materials

In previous studies, the authors demonstrated that heat-damaged hair is typically dull, less smooth and slippery, and more difficult for consumers to run their fingers through, leading to a perception of dryness. Heat-damaged hair also is more difficult to comb, less flexible and exhibits more flyaway.4 Thus, the objective of this study was to determine which silicones help defend against these effects and to compare them with other formulated materials, benchmarks and untreated hair.

While the study evaluated the company’s entire portfolio of silicones, three are profiled here; referred to throughout as silicones A, B and C:

A) a novel cationic emulsion of amine functional silicone polymera, i.e., amodimethicone (and) cetrimonium chloride (and) trideceth-3 (and) trideceth-15;

B) an (AB)n silicone copolymerb, i.e., bis-diisopropanolamino-PG-propyl dimethicone/bis-isobutyl PEG-14 copolymer (and) polysorbate 20 (and) butyloctanol; and

C) an amino siloxane hydroxy/methoxy end-blocked polymerc, bis-hydroxy/methoxy amodimethicone.

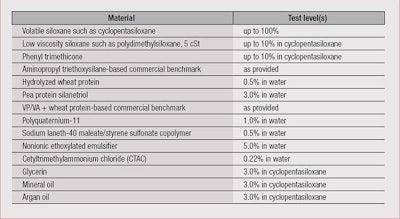

The effects of these materials were compared with those listed in Table 1. In addition, high molecular weight polydimethylsiloxane gum (dimethiconol) was used with three carriers, since dimethiconol is the market silicone reference for heat protection. These blends are referred to throughout as silicones D, E and F:

E) a volatile blend of hydrocarbon and low molecular weight dimethiconee, and

F) a low viscosity (5 cSt) dimethicone fluidf.

Test Methods

The tests performed can be broken into three stages: i) identifying the best candidate ingredients for hair heat protection capabilities; ii) applying the best candidates in a test formula to assess their effects in situ; and iii) assessing one of the top candidates to determine its mechanism(s) of action. These are explained in more detail later in the article.

Sample preparation: To assess difficult-to-straighten hair, three tresses of Caucasian frizzy virgin, Caucasian slightly bleached or curly Latino virgin hair prewashed with 9% SLS solution were used to test each material. Each tress was treated with 100 µL of 3% active silicone solution per gram of hair (unless otherwise specified) diluted in water or cyclopentasiloxane, depending on its solubility. Samples treated with the test materials shown in Table 1 were applied in the same manner. These test dilutions were used to determine the best candidates, which were applied in an illustrative leave-in conditioner cream and evaluated under the same test conditions.

Hair drying: To replicate damage caused by heat drying, tresses were dried in a 70°C ventilated oven for 20 min.

Hair damage: To simulate hair straightening equivalent to 5.5 months of daily flat-ironing (or 166 cycles), tresses were subjected to a 130-230°C oven, carefully controlled by thermocouples, for 1 min and 50 sec. This approach was used to omit friction and pressure, and to gain a fundamental understanding of only the effects of temperature. To achieve consistent results, 12 tresses were tested simultaneously and three untreated tresses always were included as a standard reference.

Quantifying protection: To quantify protection benefits, after drying and straightening, heat-damaged tresses were wetted and detangled until no broken hair was collected. Broken hairs were dried and weighed, and the resistance to breakage each treatment provided was expressed as percent improvement versus untreated hair.

Quantifying cuticle integrity: To further assess the silicone’s ability to protect cuticle integrity, optical microscopy was employed to verify single fiber cuticle damage.

Hair fiber alignment: The alignment of hair fibers was observed visually and photographed. Additionally, quantitative tests were performed by measuring hair ballooning after combing, representative of flyaways.

Silicone deposition: Scanning electronic microscopy (SEM) coupled with an energy-dispersive x-ray (SEM EDX) spectroscope was used to characterize silicone deposition.

Hair temperature: The effects of the test ingredients on hair temperature after heat exposure (oven or straightening iron) were measured using an infrared camera.

Thermostability: Thermogravimetric analysis (TGA) was used to measure any loss in mass as a function of heating rate of neat materials.

Facilitating straightening: After drying in the oven simulator at 70°C, hair was left to equilibrate in a climate-controlled room for at least 1 hr at 20°C and 50% RH. Tresses were straightened by passing a 200°C flat iron over them from one to 10 times. Photographs were taken after each pass. The facilitated straightening was evaluated by 18 panelists, who ranked the treated and straightened tresses along with one untreated tress straightened five times. Three tresses per tested product were used and the percent reduction in number of passes was calculated.

Breakage-resistance Results

Surprisingly, the diluted or formulated materials shown in Table 1 did not provide protection from heat. Additionally, 3% glycerin, mineral oil and argan oil resulted in up to 61% more damage than untreated tresses (see Figure 1). A possible explanation for these effects is discussed later in this article.

When hair was pre-treated with the benchmark 3% active dilution of silicone E, its resistance to breakage increased by 33% (see Figure 2). This set the standard against which the other silicones were compared for heat protection benefits. Indeed, among the other tested silicones, a 3% active dilution of silicone C, silicone A and silicone B provided outstanding heat protection benefits: up to 71%, 80% and 86%, respectively (see Figure 2). Silicones A and B performed similarly to the commercial heat-protection benchmark, providing 82% improvement versus untreated hair (data not shown).

To show that heat protection can be achieved on other types of hair, curly Latino virgin hair also was tested. In this case, silicones A, B, C and E preserved hair resistance to breakage from 93% to 98% (see Figure 3).

Application: Leave-in Conditioner

Once the best candidate silicones were identified, i.e., A, B and C, they were formulated into a leave-in conditioner (see Formula 1) for additional testing. The samples were applied to tresses using the same procedure as the neat materials but not diluted, as the formulas contained 3% active. Silicones C, A and B reduced the breakage of slightly bleached Caucasian hair by 61%, 74% and 82%, respectively, compared with the same formulation without silicone (control) (see Figure 4). These silicones performed significantly better than the benchmark silicone E, which showed a 21% improvement in hair breakage.

The same formulation without silicone (control) did not provide improvement compared with untreated hair, which demonstrates the direct benefits of silicones to hair. Figure 5 shows how the leave-in conditioner containing these silicones (left) helped to maintain hair health despite its exposure to heat, compared with an untreated tress (right). In addition, treated hair strands remained more aligned and supple.

Hair Cuticle Integrity

Next, the cuticle integrity of hair pre-treated with silicones B or E was assessed by optical microscopy and compared with glycerin pre-treated hair as well as untreated hair. Results showed that 3% active silicone B preserved cuticle integrity, protecting it from cracks and erosion (see Figure 6); similar observations were made with 3% silicone E (not shown). In contrast, untreated hair and hair treated with 3% glycerin showed damage including cracks and eroded areas.

Facilitated Straightening

One key consumer demand in hair care is immediate and long-lasting styling benefits but frizzy hair with flyaways undermines such effects. Thus, for optimum styling it is not only critical to lubricate hair, but also to eradicate flyway and frizz. In response, the styling benefits of silicones A, B and C were examined for effects including hair alignment, straightening and long lasting hold. Results indicated the silicones better aligned the frizzy Caucasian virgin hair with less frizz after blow-drying and before hair straightening (see Figure 7, left column; right column shows untreated and treated hair straightened after five passes with the flat iron).

In addition, flat-ironed hair treated with 3% silicones was straightened using half as many passes as untreated hair (see Figure 8). In other words, treated hair could be straightened twice as quickly as untreated hair. Furthermore, fewer passes with a heat appliance reduces the exposure time to heat, reducing the chances of damaging hair.

Finally, frizzy Caucasian virgin hair treated with the silicones and straightened 10 times was exposed to a controlled humidity room (20°C, 50% RH) for 24 hr. The silicones provided longer-lasting styling, up to 24 hr, while controlling frizz (data not shown).

Mechanisms for Heat Protection

Given that silicone B was one of the best candidates, its protective nature was observed in greater depth using SEM EDX mapping. The silicone was found to preferentially deposit on damaged zones and cuticle edges, acting as a protective agent for heat-sensitive zones (see Figure 9). This is due to the amino groups of the silicone being attracted to the damaged zones of hair, which tend to be further negatively charged.

In addition, using an infrared camera, the temperature of hair tresses treated with silicone B and exposed for 1 min in an oven at 200°C, or to five passes of a 230°C straightening iron was found to decrease as much as 20°C, compared with untreated hair. To understand the physics behind these observations, consider the following hypothetical mechanisms.

Mechanism I: Thermal Insulation

The film created by a silicone is thin compared with the radius of the hair, so the impact of its thermal insulation on one fiber is very small. An in-house mathematical model was built and showed that a 70-µm diameter, single hair fiber treated with a continuous, rather “thick” 5-µm silicone layer and exposed in an oven for 5 sec at 150°C will only experience a 10°C temperature decrease, compared with an untreated fiber.

Even if silicone possesses a rather low thermal conductivity (0.2 watt/meter Kelvin or W/m. K) and so plays the role of a thermal insulation layer, low layer thickness makes heat conduction very fast. In addition, as the total mass is small, the total thermal capacity assuming silicone’s specific heat (1.205 KJ/g. K) is small and the film will quickly reach the temperature of the surrounding environment. Therefore, no silicone treatment covering the hair fibers—even if they form a rather thick layer—protects hair against damage via thermal insulation; the silicone layer surrounding the hair fiber is simply too thin compared with the hair fiber dimension.

Mechanism II: Bound Water

Another in-house mathematical model was built, combining heat conduction and water diffusion. It showed that a single untreated fiber containing 10% bound water and exposed for 5 sec in an oven at 150°C will experience a reduction of 25°C, compared with the outcome of a mathematical model where water evaporation is not considered. The reason is the latent heat of evaporation is a very efficient cooling mechanism since it consumes a good amount of energy. As a consequence, any hair treatment that will affect the water evaporation process will influence the temperature evolution in the hair fiber.

Experiments utilizing this model showed that hair tresses treated with silicone B and ironed with three passes at 230°C lost all its bound water content (~8%), as did untreated hair. In other words, water vapor-permeable silicone treatments had a limited impact on the kinetics of water loss in the hair.

In the case of mineral oil, the amount of water lost by diffusion and evaporation was less than in silicone-treated hair or untreated hair. Mineral oil has known occlusive properties,5 which may explain the difference in the rate of water loss measured experimentally. However, as the mathematical model showed, water evaporation at the hair surface was an efficient cooling mechanism, so occlusive effects would lead to more damage or degradation. Furthermore, the silicone layer formed on hair is hydrophobic and does not affect bound water vapor release in the way glycerin does, which keeps water on the hair by its hygroscopic properties.

Mechanism III: Triboelectric Properties

Flyaway fibers standing alone are more prone to damage than when they are assembled, as they protect one another. And it is well-known in the field that silicones reduce flyaways due to their antistatic properties.6 One mechanism is simply by reducing the friction between the hair fibers and styling tool—i.e., a lubricant role. Specialty silicones A, B, or C also tend to be positively charged, reducing flyaways by neutralizing the charge at the hair surface. Therefore, the impact of flyaways on the temperature of a heat-treated hair tress also was studied.

Another in-house mathematical model was developed combining flow dynamic, heat transfer and water diffusion. It predicted that fiber assembly significantly impacts the final temperature of fibers. Per the model, a tress with fibers in close contact would reach a temperature of 77°C after a 5-sec exposure in the oven at 150˚C. On the other hand, moving the fibers farther apart would lead to a temperature of 94°C, and a single fiber would reach a temperature of 115°C. Thus, a temperature difference of 38°C could exist between individual and bundled hair fibers.

This demonstrates how the close contact of assembled fibers behaving like a macroscopic system could significantly reduce the final temperature of a tress, compared with the microscopic system of a single fiber. In fact, fibers in close proximity collectively protect surrounding fibers by more homogenously dissipating the heat carried by hot air.

Dried, silicone-treated tresses were combed three times and their ballooning angles were measured. Hair treated with 3% silicone B exhibited improved fiber contact, eliminating typical flyaway of untreated hair. In comparison, mineral oil provided less flyaway reduction than silicone B, while glycerin did not show any flyaway reduction properties (data not shown).

Finally, to obtain optimum protection, it is also key to treat hair fibers with materials that resist high temperatures of up to 230°C. As TGA demonstrated, the silicones evaluated here were heat-resistant (see Figure 10), losing no mass at temperatures up to 230°C. This is in contrast to organic materials such as glycerin and mineral oil, which show a loss in mass from 150°C (302°F).

Conclusions

Taken together, heat protection for hair is multifactorial. The silicones assessed here optimized heat protection by safeguarding sensitive cuticle zones such as partially damaged areas and cuticle edges.

Considering the possible mechanisms of heat protection, in one instance, thermal insulation by one silicone was disproven. In another instance, non-occlusive silicones did not stop bound water vapor evaporation, which decreased the temperature of flat-ironed hair by the well-known endothermic effect of water evaporation. Furthermore, the silicones ameliorated fiber contacts, resulting in decreased flyway and, in turn, lowering fiber temperatures. The sum of these factors makes the silicones assessed here good candidates for heat protection performance.

This series of evaluations shows that consumers will no longer need to compromise hair health for hair styling, or vice versa. Not all silicones offer heat protection for hair, and none of the organic and inorganic materials evaluated here offered heat protection. In fact, some even furthered the damage.

The results showed that these particular specialty silicones can offer protection from the effects of heat styling appliances, even when formulated in aqueous or anhydrous leave-in conditioners.

References

- www.cosmeticsandtoiletries.com/formulating/category/haircare/premSilicones-for-Hair-Strengthening.html (accessed May 18, 2016)

- D Istrate, C Popescu, M Möller, Nonisothermal kinetics of hard α-keratin thermal denaturation, Macromol Biosci 9:8 805-812 (2009)

- J Hahn, T Dandridge, P Seshadri, A Marconnet and T Reid, Integrating design methodology, thermal sciences and customer needs to address challenges in the hair care industry; proceedings of the ASME 2015 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, IDETC/CIE, Boston, MA, USA (Aug 2-5, 2015)

- Internal Dow Corning hair repair study

- AV Rawlings and KJ Lombard, A review on the extensive skin benefits of mineral oil, Int J Cosmetic Sci 34 511–51 (2012)

- J Jachowicz et al, J Soc Cosmet Chem 189-212 (1985)