Consumers place a significant emphasis on hair strength as one of the primary indicators of its health. In the first part of this column series,1 the use of conventional tensile testing experiments was described to generate stress-strain curves that serve in characterizing the structural integrity of individual hair fibers. It was shown that wear and tear associated with various everyday treatments and conditions does affect these properties, and physically weakens hair strands. However, it was also noted that this approach does not necessarily represent a realistic simulation of the stimuli experienced by fibers on a daily basis, nor does it seem to represent the manner by which consumers judge “hair strength.” Instead, this consumer perception likely arises from some self-appraisal of the tendency for their hair to break—for example, by noticing broken fibers in a brush or comb after grooming, or perhaps in the base of the shower after washing.

When hair is groomed, individual fibers are repeatedly exposed to the application of relatively minor forces as opposed to the one-time catastrophic deformation imparted in conventional tensile experiments. In the mechanical testing world, the tendency for materials to fail under a repeated stimulus is termed fatigue testing, and this article discusses this topic in relation to hair breakage. It will be shown that this alternative testing approach provides considerable insight into the cause of hair breakage, and subsequently allows for the identification of strategies for its minimization; it will also be demonstrated how learning this provides the underlying theory by which anti-breakage and even “strengthening” claims are crafted.

Fatigue Testing

In the previous column, it was shown that healthy, average-sized, 70-µm hair fibers require the one-time application of approximately 80 g of force to induce breakage at 60% relative humidity. It may therefore seem reasonable to presume that breakage would not occur unless everyday grooming habits and practices produce conditions that exceed this threshold. However, this is not correct, and it is well-recognized that materials will break in a predictable manner upon repeated application of stresses and strains considerably below the “break point” identified by stress-stain experiments. This happens because all materials fail at their weakest point; therefore, the presence of any structural flaw represents a nucleation site that can be propagated by a repeating external stimulus. In short, any chip, crack, or asperity in the hair structure will be progressively worsened by the repeated action of grooming and other mechanical manipulation until breakage ultimately occurs.

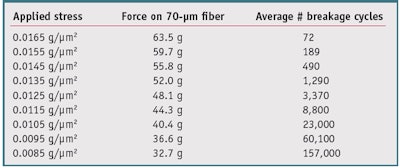

In the laboratory, single fiber fatigue experiments can be conducted using a commercially-available instrumenta. Individual hair strands are prepared in the same manner used for conventional stress-strain testing.1 The test fibers are then repeatedly exposed to a user-defined stress until the fiber breaks.2 Recall that stress is the applied force divided by the cross-sectional area of the hair fiber. A convenient means of expressing data from this testing involves an S-N Plot, where the magnitude of the repeating applied stress (S) is plotted against the number of cycles (N) required to induce breakage. An S-N Plot for healthy Caucasian hair tested at 60% relative humidity (RH) is shown in Figure 1.

In the previous column, it was noted that stress-strain curves under these same conditions yield a break stress of around 0.021 g/µm2. However, as has been outlined, breakage occurs under the repeated action of considerably lesser values. As anticipated, the tendency for breakage is related to the magnitude of the applied stress—with the repeated action of higher stresses resulting in fewer cycles to fail. Yet the logarithmic nature of the y axis indicates an exponential relationship between these two variables. This is emphasized in Table 1, which shows the average number of cycles to fail as a function of a repeating stress for this hair type under these specific conditions. It is not easy to conceive an experiment that can measure the forces encountered by individual fibers during grooming, although Figure 1 shows how conditions that produce higher fatiguing forces will lead to exponentially faster breakage. Conversely, an ability to reduce grooming/fatiguing forces will produce an exponentially lower tendency for breakage. The primary purpose of conditioning treatments is to lubricate the surface of hair and so promote manageability and improve the hair feel;3 therefore, the cosmetics industry is presented with a means of attaining this goal.

Repeated Grooming Testing

A dramatic illustration of the described theory at work can be obtained by performing repeated grooming experiments, a version of the fatigue test. As the name implies, testing involves repeatedly brushing or combing hair tresses, then counting the resulting broken fibers. In principle, such experiments can be performed by hand-grooming tresses, although an automated device is likely more reproducible and less arduous. Figure 2 shows a custom-built device that consists of a hollow rotating drum-like assembly, where four combs or brushes are mounted at 90-degree angles, allowing one complete drum revolution to brush (or comb) a tress four times. This entire set-up is duplicated three times in a horizontal direction to comb four tresses simultaneously. Collection plates are located under each tress to save broken fiber fragments, while spacer plates on the rotating drum prevent cross-contamination.4

The magnitude of the repeating stress in this fatigue experiment is not known, but it seems reasonable to presume an analogy to real-life occurrences. Moreover, as previously outlined, the ability for conditioning treatments to reduce grooming forces would be expected to yield less breakage. Figure 3 shows typical results from repeated grooming testing and illustrates the sizable benefit associated with conventional conditioning products. Notably, testing was performed on chemically damaged hair, as a chemical treatment generally leads to increased grooming forces that subsequently produce a higher tendency for breakage. Therefore, the benefits of conditioning products are exacerbated when testing on a more vulnerable hair substrate. By this method, it is typical for traditional rinse-off conditioners to reduce breakage by 70-80%, while a leave-in conditioner may produce benefits as high as a 90%.

Strictly speaking, repeated grooming experiments demonstrate the ability for conditioning products to reduce the tendency for breakage, but the sizable benefit that arises is often described by the consumer as “making the hair stronger.” Accordingly, this approach is behind quantitative anti-breakage claims, e.g., “this product reduces breakage by 80%,” but results are often extrapolated into “strength” claims. Again, it is emphasized that the tensile properties of hair fibers have not been altered in any way, and this “strengthening” proposition solely relates to “consumer language” rather than the strict scientific definition.

Modeling Hair Breakage

Additional modeling of single fiber fatigue data further emphasizes the influence that surface friction/lubrication has on the tendency for hair breakage. By borrowing principles from the greater fatigue testing field, it becomes possible to fit a cumulative statistical distribution to the data shown in Figure 3. The intriguing outcome of this transposition involves breakage now becoming a statistical variable as opposed to a mechanical parameter.2, 5 Accordingly, it becomes possible to predict the likelihood for a fiber to break or survive under a specific set of conditions.

The outcome of this analysis is termed a Survival Probability Plot, and Figure 4 shows three such curves that were derived from single fiber fatigue experiments. The plots show the probability that a hair fiber will survive under a given set of fatiguing conditions. The black curve shows a steady decrease in the survival probability of virgin Caucasian hair as a function of increasing applications of a 0.009 g/µm2 stress. The blue curve indicates the lower likelihood for bleached hair to survive under these exact same conditions. Finally, the red curve indicates the dramatically greater effect associated with a 40% increase in applied fatiguing force on virgin hair.

It is well-entrenched in the minds of consumers and hair care scientists that chemical treatments weaken hair and lead to higher breakage. The traditional scientific explanation for this occurrence involves depletion of strength-supporting cystine cross-links within the hair structure. However, it appears that this explanation is only partially true. Conventional tensile measurements show diminished mechanical properties after these treatments but the effects generally are rather minor. For example, a permanent coloring treatment will likely decrease the dry-state break stress by 5% or less. Of course, consumers repeatedly apply such treatments every 4-6 weeks because of new hair growth, and it is well-known that compromised hair is more prone to additional damage. It is still perhaps somewhat surprising that relatively meager changes in tensile strength lead to such large consumer-perceived effects. The data in Figure 4 provides an explanation for this occurrence; that is, chemical damage also increases grooming forces that subsequently translate into higher fatiguing forces and an exponentially higher tendency for breakage. Indeed, this model suggests that the contribution from this increased friction greatly outweighs the compromised tensile properties in terms of exacerbating hair breakage.

Summary

Modeling associated with single fiber fatigue testing experiments provides novel insight into the contributors for hair breakage. For example, much has been stated in this article about the exponential relationship between the applied stress and the tendency for breakage. However, recall that stress represents force per unit area, and so there is also an exponential relationship between the dimensions of hair and the tendency for breakage. In short, it is evident that individuals with fine hair are greatly predisposed to higher levels of breakage. Another especially noteworthy, and rather unexpected, discovery from this work involves the considerable effect of the relative humidity on breakage—where high humidity conditions lead to an especially high tendency for breakage.1, 5, 6

Interestingly, this fatigue approach generally shows larger differences between treatments/conditions than seen when performing conventional tensile testing. For example, a 10% reduction in break stress by the traditional approach may equate to a tenfold decrease in the number of cycles-to-breakage in a fatigue experiment. Consequently, it is entirely possible that the tendency to perform quick and easy stress-strain experiments as an indicator of hair “strength” has led to considerable underestimation as to the effects of deleterious treatments and conditions on the propensity for hair breakage. Nonetheless, the findings described herein also suggest the best means to address this issue. Namely, the use of conditioner treatments that lubricate the hair surface leads to a reduction in fatiguing forces and allows the S-N Curve to work in the formulator’s favor. As such, dramatic decreases in hair breakage are obtained without any alteration of the intrinsic tensile properties.

The drawback of the single fiber fatigue approach, at least in its present form, involves the slow rate of data acquisition. Moreover, a high number of data points are required for suitable confidence in outcomes and consequently, this approach is best viewed as a research tool as opposed to a screening technique. However, repeated grooming experiments represent a dramatic and highly consumer-relevant manifestation of the underlying theories that are more appropriate as a routine testing method.

References

- TA Evans, Measuring hair strength—Part 1: Stress-strain curves, Cosm & Toil 128(8) 590–594, (2013)

- TA Evans, Fatigue testing of hair—A statistical analysis of hair breakage, J Cosmet Sci 60 599–616 (2009)

- TA Evans, Evaluating hair conditioning with instrumental combing, Cosm & Toil 126(8) 558–563 (2011)

- TA Evans and K Park, A statistical analysis of hair breakage. II. Repeated grooming experiments, J Cosmet Sci 61 439–455 (2010)

- TA Evans, Hair breakage, in Practical Modern Hair Science, T Evans and RR Wickett, eds, Allured Business Media, Carol Stream, IL USA (2012)

- TA Evans, A statistical analysis of hair breakage, part III–Modeling the contributors to hair breakage using fatigue experiments, in press