Three-dimensional (3D) printing is literally popping up in many fields, including in cosmetics and personal care product development. First observed by Cosmetics & Toiletries in the packaging concept departments of major R&D manufacturers, 3D printing has hit the mainstream. But is its use feasible? Perhaps for packaging mock-ups, but not likely to "print out" quality cosmetics at home.

On April 2, 2014, the in-cosmetics event in Hamburg featured a presentation by Antoinette van den Berg, founder of Future-Touch, on 3D printable technologies for cosmetics—especially novel packaging concepts from Marketing. Also, just a few weeks later, at the Society of Cosmetic Scientists' April Symposium, company Active 3D presented how 3D printing works, in consideration of its potential for personal care.

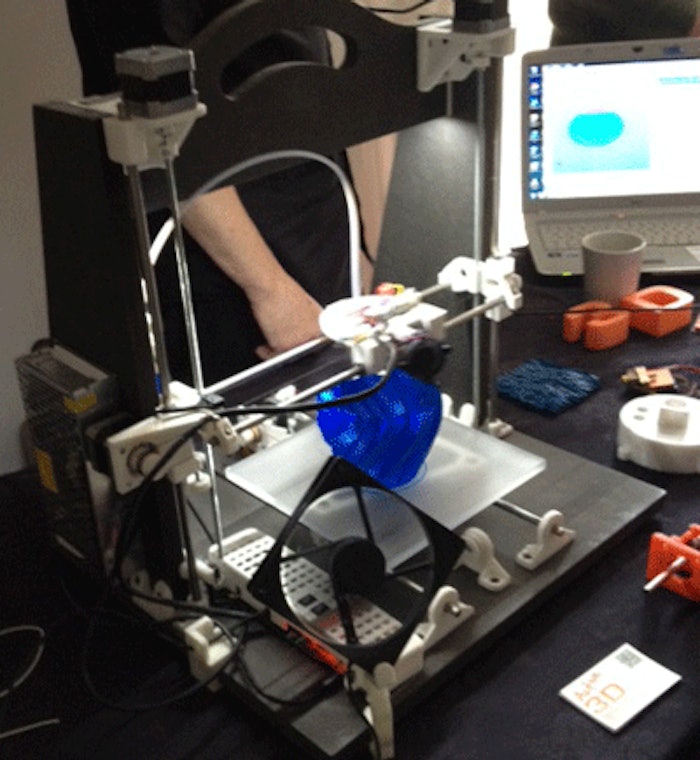

According to the company, to say a 3D printer "prints" is a difficult concept to understand until one is seen in action. Most printed items have until now been in 2D; e.g., a letter, which has a width and height. With 3D printing, of course, there is also depth.

"Imagine your current 2D printer, printing the same letter over and over, onto the same piece of paper," states the company website. "If the ink were to dry before each next print cycle, the text on the letter would eventually get thicker and thicker, turning into some kind of 3D letter. That’s what 3D printing is, except using other materials than ink, such as plastic, wood and metal."

The company's printer layers materials such as plastic to form a solid object. It melts a plastic filament, then draws with it in a very fine layer, and builds another layer of plastic on top, over and over, following the 3D design from the bottom up until the object is complete and ready for use.

At an upcoming SCS event, "Packaging Unleashed," to be held June 17, 2014, in Bristol, UK, a 3D printer will be operated throughout the day by HK Holdings to demonstrate this. Such a technology is suggested to assist in the design of cosmetic packaging, benefiting companies in speed to market, prototyping and short-run production, saving development time and even wasted materials.

In relation, at an event called TechCrunch Disrupt, held in New York on May 5-7, former Harvard Business School student Grace Choi presented an idea for a device based on 3D printing, which she calls Mink. Mink reportedly can print color cosmetics such as eye shadows, blush, etc., in any color using existing computer software onto various substrates. Choi noted that by inputting the hex code for a color into Photoshop or Paint and clicking "print," a product is developed; she added that Mink costs less than $200, and she plans to launch it later in 2014.

This story created some buzz, and consumer magazine Harper's Bazaar picked up on it in its May 9 story, "Why You Can't Print Quality Cosmetics." In it, Joyann King interviewed Jim Hammer, a cosmetic chemist of Mix Solutions Consulting, who stated, "I think it is far from actual implementation because Choi does not have a cosmetic chemist's grasp of the underlying technologies required to make this work." He explained how the colorants used in cosmetics are often insoluble powders and not the same as inks used in typical printers.

While Choi's concept may at first seem too idealistic and expensive for consumer adoption, it could in theory simplify some basic formulation work in R&D labs; although this would certainly seem to smash any hope for mentoring a new generation of skilled formulators.