Throughout the many (40) years I have been in the personal care industry—and more specifically, working with silicone polymers (30 years)—an article written in 1984 is, I believe, one of the best articles I have ever read written about PEG/PPG dimethicone compounds; even being 34 years old and written in the early silicone-era days.

The article was written by Steven Vick, Ph.D., of what then was Union Carbide. What makes the article so great is that it provides real, timely (despite being 34 years old) and useful information that can help the formulator immediately.

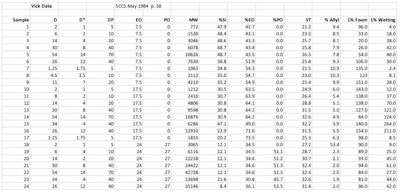

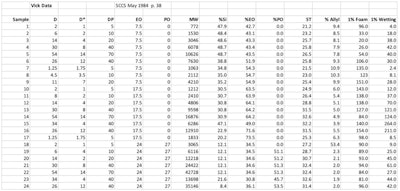

A very "busy" table from the referenced paper (see Table 1) reveals the entire structure, molecular weight, surface tension of a 1% solution, foam and wetting data of PEG/PPG dimethicone. In short, at a glance, it shows all the data a chemist really wants to know. These materials, all water-soluble, are described in a way that takes the guess work out of selecting them for a particular function in a formulation.

Table 1. PEG/PPG Dimethicone Properties (click to enlarge)