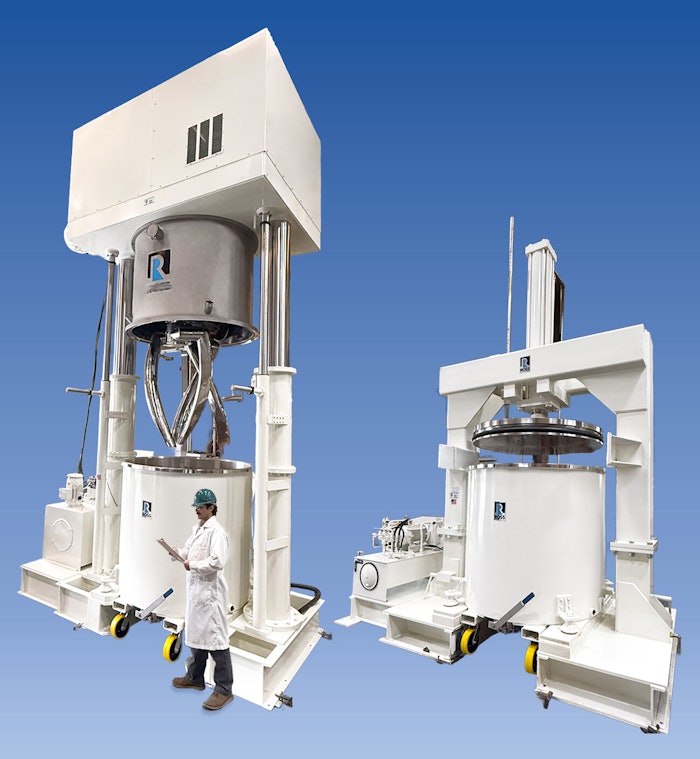

ROSS has announced the completion of the largest Double Planetary Mixer in history, Model DPM-750. This large-capacity mixer is engineered for processing up to 750 gallons of highly viscous materials per batch and is designed to operate within Class I, Division 1, Group D hazardous environments.

Planetary Motion for Viscous, Sticky Substances

The heavy-duty industrial mixing equipment uses a 150 HP inverter-duty motor to drive two high viscosity (HV) stirrers. These stirrers move in a planetary motion, a configuration suited for processing very thick, sticky or dense substances. The unit is also equipped for vacuum mixing up to 29.5 in Hg, which helps produce a void-free final product and can improve dispersion quality.

Additional features include:

- a custom vacuum hood with ports for ingredient charging, exhaust and observation;

- all product contact parts are constructed from stainless steel type 304 with an 80-grit polish; and

- the design incorporates interchangeable mix cans to allow for more flexible batch processing.

Safe Operation and Full Batch Discharge

For operational safety and positioning, the equipment includes a dual-post hydraulic lift powered by a 10 HP explosion-proof motor. This system is fitted with dual hydraulic pumps and integrated locks with proximity switches. Safety interlocks are in place to prevent operation unless both the stirrers and the mix can are correctly positioned. A companion ram-type discharge system is designed for product transfer and cleaning, using a pressure-compensating hydraulic system to maintain 60 PSI under the platen to facilitate the discharge of a full batch.

!['[W]e can predict better ingredients, faster, with our best-in-class models that we have invested in over several years,' says Joshua Britton, Ph.D., founder and CEO of Debut.](https://img.cosmeticsandtoiletries.com/mindful/allured/workspaces/default/uploads/2025/08/debut-biotechnology.c4slA2p7t3.jpg?auto=format%2Ccompress&fit=crop&h=191&q=70&w=340)