*Editor’s note: Sometimes, a second look is all it takes to reinvent an old favorite or uncover hidden answers. Cosmetics & Toiletries has therefore dusted off its bound volumes to give readers another look at this December 2001 article on flexabrasion for measuring hair strength.

Tensile test methods have been successfully used to demonstrate improvements in the mechanical properties of hair, however they assess only one aspect of the physical processes of hair fracture that the consumer normally uses to evaluate the strength of hairs on the head. A more realistic test would involve all the elements—fiber bending (flexure), abrasion and extension—encountered in normal hair fracture. This paper provides background about a test method that does measure an amalgamation of these three elements, and gives examples of its use to evaluate a new ingredient for hair products that increases the strength of bleached hair.

Tensile Strength

The need for claims substantiation: In addition to the paramount need to ensure product safety, the cosmetics and toiletries industry is under increasing pressure from various authorities to justify advertised claims, particularly new ones. This is to ensure the protection of manufacturers from competitors who might otherwise gain an unfair advantage in the marketplace by false or unsubstantiated claims of benefit. There are two main routes to meeting this need for product claim substantiation, presented individually or, on occasion, presented in mutual support. The more difficult and expensive route analyzes panelists’ reactions to the use of the product. Recognized and reliable methods of experimental design and of statistical analysis are employed to seek out the significance of the particular benefit.

The other main route for claim substantiation is by laboratory instrumental evaluation. This route is the focus of the present paper. The advantage of this route for the product developer, particularly where isolated strands of hair are tested, can be in the ability to rapidly screen experimental materials and finished products for their effectiveness.

Whatever method is deployed, it must be in realistic accord with the conditions under which normal hair breakage occurs.

Lack of realism: A common dictionary definition of strength is the quality of “not being easily broken.” Such is the concern of consumers in the everyday cleaning and styling of their hair when the fibers break more frequently than they regard as acceptable. Through the development of suitable products, however, the hair toiletries industry can target this problem and advertise its products with an associated claim for increased hair strength.

It is in many ways unfortunate that the focus of attention amongst most toiletry manufacturers, aided and abetted by instrument makers, has been upon the tensile properties of hair fibers as a measure of their strength. This makes use of an apparatus in which a segment of the fiber, fixed at either end, is subjected to increases in extension during which the load is continuously monitored.

Several parameters might be derived from such load-extension curves for treated hairs that, in comparison with those for untreated fibers, show the particular treatment has increased their tensile strength. Unfortunately, some of these parameters are not very realistic in relation to the physical conditions to which hairs are normally subjected on the head during cosmetic processing and manipulation. Thus, parameters such as “load to break” or “the post yield modulus” are often measured under conditions that, were they to have occurred on the head, would have extracted the hair from its follicle.

Other mechanical stresses: There is another reason for not recommending the exclusive use of load-extension methods for measuring the hair’s ability “not to be broken easily.” The mechanical stresses leading to hair breakage are not merely tensile. The consumer is most aware of hair breakage during combing. Thus, for evaluating hair strength, it is preferable to choose a laboratory test method that reproduces, as far as is practicable, the physical stresses prevailing during combing.

One of the [present] authors, over many years, has investigated the way in which hairs break. These investigations began in 19751 with observations on the combing of tangled hair. A scanning electron microscope was used to look at miniature hair tresses in which tangles had been produced by teasing. Records on videotape, in which the movement of hairs could be likened to a seething sea of snakes, showed several key events:

- Hairs were forced to bend over each other in tight radii of curvature (in some cases to the curvature of the contacted hair).

- There was intense frictional interaction between the hairs as each moved toward its tip end to be released from the tangle, with occasional stripping away of fragments of cuticle.

- The bend in each hair was propagated toward the tip. During this propagation, longitudinal spliting and even breakage sometimes occurred.

While the force for these processes was provided by the comb, it was noticeable that more damage tended to be inflicted upon the hairs through fiber-fiber interaction than between the fibers and the tines of the comb.

These experiments showed that the major stresses leading to hair fracture during combing were flexure (or bending), abrasion and tension in the individual fibers. Of these, flexure was established as most important and the initiator of all the subsequent events culminating in hair breakage.

Flexabrasion

Roots in the textile industry: The repetitive drawing of single hairs under load, backwards and forwards over a wire at 90 degrees (Figure 1), reproduces all the elements of stress (flexure, abrasion and tension) under which hairs normally break on the head. Consequently, this is an ideal laboratory test for evaluating hair strength. A method that counts the number of cycles required to break the fiber was originally developed for use in the textile industry under the name flexabrasion test.2

Variability between hairs: In 1995, Leroy et al.3 were the first to report using the test to evaluate human hair. For any given hair fiber, they measured the fracture lifetime, which is the number of cycles before fracture occurred. Then, using Weibull statistics, they analyzed their results from approximately 100 hairs for each treatment being evaluated.

This analysis disclosed a valuable fact: the fracture lifetime decreased from the root-end to the middle to the tip-end of weathered hairs. It also showed a significant reduction in fracture lifetime as hairs were bleached. Finally, it showed that the fracture lifetimes of bleached hairs could be increased to approximate those of unbleached hair by treating the bleached hair with various acid-containing hair shampoos.

Variability within a hair: A significant improvement in the flexabrasion methods of Leroy et al. was made by Pykett and Swift4 in recognizing that the variability in the number of cycles to fracture would be much less between adjacent short segments within a given hair than between different hairs. This meant that adjacent segments within each hair could be tested, with one segment used as a control and the other segment used to evaluate the experimental treatment. This dramatically reduced the number of hairs needed for flexabrasion testing for a given level of statistical significance in the fracture lifetimes for the experimental and control treatments, as compared with the original methods of Leroy et al.

Pykett and Swift4 demonstrated the expected low level of the within-hair variability as compared with the much higher level of between-hairs variability. By testing a series of 12 segments from within a single weathered hair, they also found a smooth reduction in flexabrasion cycles to fracture from approximately 6,000 at the root end to about 100 at the tip end.

Effect of humidity: [The authors’] investigations of the flexabrasion method have involved the construction of new equipment and new methods for mounting the hair segments. The full details of these modifications have been published recently,5 but it is pertinent to mention that 20 hair segments can be tested at each run (i.e., 10 within-hair pairs; each hair is 14 mm long) and there is full control over relative humidity (RH) and the frequency of flexabrasion cycling.

Using this equipment, [the authors] have reported5 that as RH increases, the number of cycles to fracture for root-end untreated hairs increases gradually to a maximum at 80% RH and then falls off precipitously at 90% RH. [The authors] also found that the number of cycles to fracture for untreated hair was a factor of 2.1 greater for pre-wetted fibers as compared with pre-dried fibers 2 hr after they had been exposed to a forced circulation environment at 60% RH.

In addition, [the authors] established that the cycles to fracture for untreated hair at 60% RH decreased by a factor of 2.7 as the frequency of flexabrasion cycling was increased from 0.25 to 8.0 Hz.

Methods and Materials

To further demonstrate the effectiveness of the flexabrasion test, [here the authors] present results in which a new ingredient for inclusion in hair products is shown to increase the strength of bleached hair.

Research into the performance of this and other cosmetic ingredients is still underway; therefore declaration of the composition of the new ingredient can not be undertaken at this time.

In one set of experiments, the loss in strength was evaluated for the bleaching of untreated hair. In another set of experiments, the flexabrasion lifetimes (i.e., number of cycles to fracture) for simple leave-on and for rinse-off aqueous treatments of bleached segments were compared with the corresponding bleached but otherwise untreated segments. In a final experiment, comparisons were made between bleached hair segments treated with a conditioner base with and without the inclusion of the new active ingredient.

Hair samples: Hair fibers were taken from a single unbound 250-g, 25-cm swatch of virgin brown haira. The hair fibers used were untreated and mounted carefully with minimum handling to prevent any damage that may reduce the fiber flexabrasion lifetimes.

Specimen preparation: Two adjacent 14-mm segments were taken from the root end of the same hair fiber and mounted onto brass tabs using cyanoacrylate glue. One segment was used as a control and the second for the test treatment. The mounting procedure is described in Figure 2.

Flexabrasion equipment: The test equipment was custom built to [the authors’] requirements. It has the capacity to run 20 hair fiber segments at one loading. The equipment moves these 20 hair segments backwards and forwards at right angles over a drawn tungsten wire (0.2 mm diameter), as illustrated in Figure 1. The reciprocating motion has a total linear displacement in each direction of 4 mm and a frequency of 2 Hz. A constant load of 12 g is placed on the hair segments.

The number of flexabrasion cycles is logged through a series of digital counters, one for each hair segment, which stop when the corresponding segment breaks and triggers an electro-mechanical switch. The whole apparatus is placed inside a force circulation temperature- and humidity-controlled cabinet.

Standard bleaching protocol: A flat, pre-bound tress (1 cm width) of the virgin brown hair was bleached using a solution of hydrogen peroxide (6%) and ammonium persulfate (5%) at pH 9.5 for 30 min. The tress was then rinsed under tap water for 3 min. Excess moisture was removed by placing the tress onto a paper towel. The tress was dried overnight under ambient conditions. Adjacent 14-mm sections from individual fibers were obtained and mounted in the manner described above.

Flexabrasion conditions: The flexabrasion tests were all carried out at 60% RH and 23°C using a 4-mm hair displacement at a frequency of 2 Hz.

Results and Discussion

Effect of bleaching virgin brown hair: This experiment was carried out to assess the degree to which bleaching causes a loss in hair strength. The damage was assessed by measuring the change in flexabrasion lifetime between the within-hair paired segments. Untreated virgin fibers were mounted according to Figure 2. The A segments were soaked in water for 30 min and then dried under ambient conditions for one day. The B segments were bleached for 30 min as detailed in the bleaching protocol. These were then allowed to dry under ambient conditions for one day.

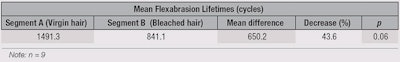

Segments A and B were mounted in the flexabrasion apparatus in the absence of any tensile stress and were conditioned at 60% RH for 1 hr. The hair fiber segments were then lowered into their final position under the 12-g load and the flexabrasion test was carried out. Flexabrasion lifetimes for both segments are recorded in Table 1.

Effect of active applied from aqueous solution: Two experiments were carried out to assess the effect of a hair-strengthening active when applied from aqueous leave-on and rinse-off systems. For each system, a 1% active solution of the hair-strengthening active was used. The solutions were adjusted to pH 5.5 using sodium hydroxide solution.

Hair was taken from a pre-bleached swatch and mounted as described in Figure 2.

The B segments were soaked in the active solution (pH 5.5) for 20 min. In the case of the rinse-off treatment the segments were rinsed with 50 mL distilled water, and for the leave-on treatment, the segments were simply allowed to drain excess solution. These segments were then allowed to dry under ambient conditions for 24 hr.

The A segments were soaked in water for 20 min (pH 5.5) and then dried under ambient conditions for 24 hr.

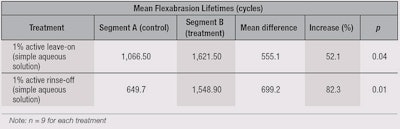

Both A and B segments were then conditioned, without load, at 60% RH for 1 hr before measuring their flexabrasion lifetimes. The results are shown in Table 2.

Effect of active applied from conditioner formulation: An experiment was carried out to assess the effect of the hair-strengthening active from a conditioner formulation (Formula 1). The active was mixed with the conditioner base to a final concentration of 0.25% for the test conditioner. The conditioner base alone was used for the control treatment. Prior to their use, the test and control conditioners were adjusted to pH 5.5 using sodium hydroxide solution.

Hair was taken from a pre-bleached swatch and mounted as shown in Figure 2. The B segments were soaked in the test conditioner (pH 5.5) for 10 min, then removed and rinsed with water (50 mL). This was repeated four times, after which the segments were dried under ambient conditions for four days.

The A segments (control) were soaked in the conditioner not containing the active for 10 min and then rinsed with water (50 mL). This was repeated four times, after which the hair segments were allowed to dry under ambient conditions for four days.

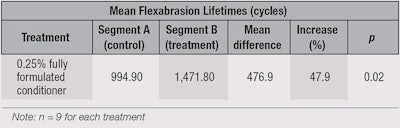

The segments were then conditioned, without load, at 60% RH for 1 hr before measuring their flexabrasion lifetimes. The results are shown in Table 3. Figure 3 summarizes the improvements in strength of bleached hair brought about by the different treatments with the new active ingredient.

Conclusion

The flexabrasion test was used to demonstrate the effectiveness of a new active for increasing the strength of bleached hair by leave-on and by rinse-off aqueous treatments and as incorporated within a fully-formulated conditioner. In each case, the results were obtained by using only nine hair fibers.

References

- JA Swift and AC Brown, Hair breakage: The scanning electron microscope as a diagnostic tool, J Soc Cosmet Chem 26 289 (1975)

- WE Morton and JWS Hearle, Physical Properties of Textile Fibers, The Textile Institute, Manchester, England (1993)

- F Leroy, A Franbourg, JC Grognet, C Vayssie and D Bauer, Flexabrasion: A new test for predicting human hair resistance, poster presented at the 1st Tricontinental Meeting of Hair Research Societies, Brussels (Oct 8-10, 1995)

- M Pykett and JA Swift, Schutz von Haarbruch nachweisen; Ein neues Testverfahren für bessere Datenbasis, Parf u Kosmetik 79 38 (1998) (English title: Demonstrating the protection of hair from breakage: A new test procedure for better data analysis)

- JA Swift, D Coulson and MF Al Bayatti, The intra-fiber flexabrasion test: A powerful method in the evaluation of hair toiletry products, proc 10th Internat Wool Textile Res Conf, Aachen HH-8 1-10 (2000)

!['We believe [Byome Derma] will redefine how products are tested, recommended and marketed, moving the industry away from intuition or influence, toward evidence-based personalization.' Pictured: Byome Labs Team](https://img.cosmeticsandtoiletries.com/mindful/allured/workspaces/default/uploads/2025/08/byome-labs-group-photo.AKivj2669s.jpg?auto=format%2Ccompress&crop=focalpoint&fit=crop&fp-x=0.49&fp-y=0.5&fp-z=1&h=191&q=70&w=340)