All microorganisms need sufficient water and nutrients to grow. The concept of controlling water activity to prevent this growth is as old as time, and the practice of using water activity to prevent spoilage began with honey. Honey would appear to be the ideal growth medium for microorganisms—it contains water and sugar—but it is in fact an excellent example of a self-preservating product because the sugar ties up the water molecules, making the water unavailable for microorganism growth. This is a simple example of the very important difference between water content and available water, alsoknown as water activity.

Water activity is written as aw and is defined as the ratio of the water vapor pressure of the product compared to pure water at the same temperature, where P is the vapor pressure of the product, Po is the vapor pressure of pure water, n1 is the number of moles of solute, and n2 is the number of moles of water:

aw = P/Po = (n2/(n1 + n2))

Eq. 1

Pure water has an activity of 1.00 while something considered “bone dry” is 0.00. It is numerically equivalent to 1/100 of the relative humidity (RH) generated by the product in a closed system. RH can be calculated from the direct measurements of partial vapor pressure or dew point, or indirect measurements by sensors that are altered by being exposed to RH. Thus, the relationship between water activity and the equilibrium relative humidity (ERH) is:

ERH (100%) = aw x 100

Eq. 2

Although it is possible to calculate water activity, measurements are significantly more accurate when taken instrumentally. The food industry has used water activity for many years to determine the need for preservatives.

Measuring Water Activity

There are several ways to measure water activity, including: vapor pressure manometry, electric hygrometry, hair hygrometry and dew point. The Association of Analytical Communities (AOAC) officially recognizes the dew-point/chilled mirror method.

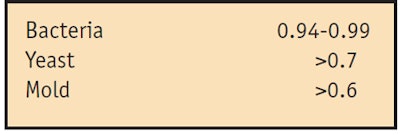

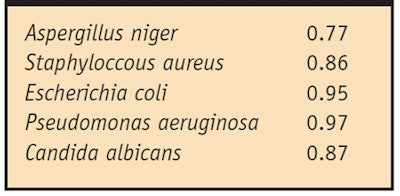

The approximate water activity needed for growth of various micro-organisms has been published and these amounts are generally recognized as the minimums needed for growth (see Table 1). The specific water activity needed for growth of the five common test organisms is shown in Table 2. It should be noted that some molds can grow with water activities as low as 0.7; therefore, it is a good rule of thumb that water activity be kept below 0.7.

Robert Friedel published one of the earliest papers on the use of water activity to determine the requirements for preserving topical products.1 This work showed how water activity could be measured using a dew-point/chilled mirror instrument to obtain accurate and reproducible resultsa. Among the examples given were creams, gels, anhydrous lip balms and ointments.

Water activity has become a valuable tool to determine the potential for growth in raw materials. Since microbiological specifications are required by the European Union for all cosmetic ingredients, assuring whether the water activity of a product is below 0.7 determines the need for micro-testing of ingredients. Equally of value is determining the activity of the finished formulation before adding preservatives. If it is found that only mold or yeast can grow in the product, there is no need to add preservatives that are active only against bacteria.

There are certain ingredients that have been shown to lower water activity—salts, such as Dead Sea salts; glycols and polyols, such as glycerin, propylene glycol and polyethylene glycol; a series of commercial mixturesb that, at 15–20%, may make a product self-preserving—however, there appears to be no linear relationship between specific levels of these ingredients and water activity. Models have been published to predict the effects of adding water-binding ingredients to lower water activity, but due to the complex nature of cosmetic formulations, these models do not predict the outcome accurately. Measurement by instrumentation is the best way to achieve accurate results.

Attempts have also been made using high amounts of glycols to lower activity so that no additional chemical preservative is needed; however, the esthetics of the resulting products were unacceptable.

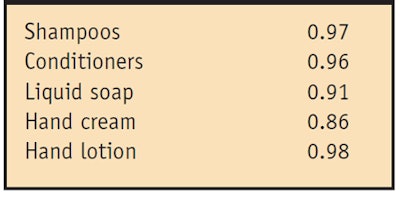

Measuring water activity is especially useful for formulations that are atypical, such as: w/o emulsions, low-water content products, anhydrous products such as lipsticks and powders, and water extracts where the addition of high levels of glycols, even as extracting solvents, can be used to lower the water activity below 0.7 to avoid the need for additional preservatives. Some typical water activities of various personal care products are shown in Table 3.

It is critical to understand that water activity is not cidal, meaning it does not kill microbes; it only prevents growth. Therefore, it can only be applied to products that are already free of contamination. As water activity can only be determined by measurement, hazard analysis critical control point (HACCP) is an important concept applicable to both raw materials and finished formulations.

HACCP

The concept of HACCP was originally developed for the space industry to assist in producing food for astronauts. The purpose was to provide a high degree of quality and microbiologically safe foods. Hazard analysis identifies critical control points (CCP) and relates to contamination. HAACP is currently mandatory in the food industry; the US Food and Drug Administration (FDA) is also encouraging its use for the drug industry. It is very useful for the production of cosmetics.

CCP can be used in every process and design during the manufacture of cosmetics. It is used to identify locations where contamination could occur. If manufacturers choose not to incorporate traditional active preservatives or rely on water activity or other non-preservative methods, HACCP is a valuable tool to ensure quality.

It has been a general belief that the purpose of preservatives is to make a cosmetic remain in its “clean” condition under normal consumer use and to protect products from consumer contamination. In reality, preservatives or preservative systems should prevent contamination from occurring during production. Formulators never know for certain if the production of a clean cosmetic was achieved by strict adherence to current good manufacturing practices (cGMP), or whether the preservative system prevented incidental contamination.

To illustrate the point, consider the following: When a batch is produced and found to be contaminated, this is referred to as a “preservative failure.” The FDA does not permit post-manufacturing treatment by external means like radiation, heat sterilization or pressure to reduce contamination to acceptable levels. When products are challenge-tested to determine their adequacy of preservation, they are usually challenged with pure cultures. Also strongly recommended is the introduction of house isolates to be certain that the system is strong enough. But how could a consumer possibly contaminate a cosmetic with a manufacturer’s house “bugs”? Or with a pure strain of bacteria? The focus needs to be on controlling and preventing microbial contamination during manufacture, thereby removing the onus of enforcing regulations from the formulator.

References

1. R Friedel, The application of water activity measurement to the microbiological attributes testing of non-sterile over-the-counter drug products, Pharmacopeial Forum 24 2 (Mar–Apr 1998)

2. J Kabara and D Orth, Preservative-free and self-preserving cosmetics and drugs, Dekker (1997)

3. G Borovian, HACCP application in the manufacturing of drugs and personal care products: microbiological testing centered on prevention, presented and published at Preservatech USA (Chicago) (1999)

4. M Easter, Implementing HACCP in the manufacture of personal care products, presented and published at Preservatech (Paris) (1996)

5. ILSI Web site, A simple guide to understanding and applying the hazard analysis critical control point (HACCP) concept, available at http://europe.ilsi.org/file/ILSIHACCP3rd.pdf (Accessed Jan 4, 2007)

6. InHouse Trainer, Technical Consultancy Services Web site, available at www.techconsult.com.au (Accessed Jan 4, 2007)