* Adapted from T Evans and RR Wickett, Advances in hair styling, in Practical Modern Hair Science, Allured Business Media: Carol Stream, IL USA (2012).

Inherent hair factors including variations in the morphology and mechanical properties of hair impact styling. For instance, thicker hair is more difficult to style and the style is more difficult to retain. Cuticle edges are another factor; hair with less frequent cuticle edge intervals is more flexible and easier to bend and manipulate, which has a significant influence on the durability of a hair style. Hair shape itself also influences the ease of styling, with spherical-shaped hair being more difficult to style than elliptical shaped hair. While these characteristics are important considerations, the cosmetic chemist obviously can only control external factors such as the features of products or functional ingredients applied to hair.

Styling products take on a myriad of forms. One level of differentiation is whether they are applied to hair as a thickened liquid or a spray. With aerosols, the product is atomized either mechanically using specialized pumps or with pressurized liquefied propellant gases such as propane. Other products include clear to translucent gels, cream gels, low viscosity lotions, pomades, taffies, stringing pomades, light-airy soufflés and clays and waxes.

In some cases, there is an overlap between aerosol technology and products that do not require atomization. For example, aerosol mousses rely on a propellant as part of the delivery mechanism to produce foam. There are also foam mousses produced mechanically using a special actuator. Spray gels require mechanical breakup as non-aerosols but the product form in the container is a gel.

Formulation Variables

All formulations start with a framework; styling gels consist mainly of the fixative resin and the gellant, whereas aerosol mousse includes the propellant, resin solution and a foaming agent. The essential components can be adjusted to obtain the correct viscosity, flow and foaming but on top of these frameworks are added auxiliary ingredients to fine-tune the formula with respect to aesthetics, added benefits and compliance to quality, such as the use of preservatives. The main type of ingredient added to styling product vehicles is the fixative resin. Here, usually a high molecular weight and water-soluble polymer dries into a resinous film that imparts the desired mechanical properties of stiffness and elasticity to the hair fibers or fiber assemblies. The chemistry of these polymers has evolved over the past 50–60 years and new monomer combinations with various functional groups have increased the features and benefits these polymers provide.

The film qualities of a resin can be modified with auxiliary ingredients such as plasticizers. The addition of a polyhydric alcohol such as glycerin or an ethoxylated nonionic surfactant or emollient such as PEG 75 lanolin will tend to soften the film on the hair. This is due to the disruption of the interactive forces of the polymer molecules in the resinous film, increasing film pliability. The result is reduced flaking during combing, a problem with some homopolymers such as PVP, and improved smoothness properties. The negatives, however, may be a compromise of other fixative properties, such as hold under humid conditions and reduced stiffness. This is the case with most cream gels that have a certain amount of oil, whether it is organic, petroleum- or silicone-based, dispersed in the gellant. These gels compromise fixative properties for other benefits such as anti-frizz effects, which require the addition of silicone. Examples of commonly used silicones include low and high molecular weight dimethicone and dimethiconol, and phenyltrimethicone. A typical cream gel designed for normal and undamaged hair contains a small oil phase so that the oil does not weigh the hair down and negatively affect hair volume and body, while providing enough oil to enhance hair shine, condition and styling.

The level and type of neutralizing agent for fixative polymers that require neutralization, e.g., those with a carboxylate group, will tend to affect film properties as well. Organic amines such as aminomethylpropanol (AMP) and triethanolamine (TEA) will have more of a plasticizing effect than an inorganic alkali such as NaOH. Organic amines may reduce film hardness and, in some cases, high humidity curl retention.

Besides the fixative, fixative modifying and gelling ingredients, other components may include preservatives, chelating agents, UV absorbers, fragrance and fragrance solubilizers, feel modifiers and color. One could get the impression from this that formulating a fixative product could get quite complex—and the formulation challenges become magnified when the product format contains a novel texture. A guiding principle or formulation strategy to keep in mind is to be specific on the profile of the product with respect to both aesthetics and performance, and to choose ingredients appropriate for these outcomes. During formulation development, performance must always be evaluated in parallel with aesthetics. Many a formulator has spent too much time getting the right type of foam in a mousse or feel in a cream only to discover that the added foaming or feel modifying agents lowered the required performance efficacy.

Advances in Fixative Polymers

In the 1950s, the first synthetic resin promoted for hair styling was polyvinylpyrrolidone (PVP).1 PVP has excellent water solubility and compatibility with gelling agents such as carbomers and forms a resin on hair that imparts stiffness. Very early in PVP’s career, many drawbacks to its resinous film became evident, such as poor humidity resistance and flaking.2 This sparked an evolution of modified polymers to overcome these drawbacks. The strategy was to copolymerize two or more monomers with various functional groups to make copolymers. Over several decades, a whole family of polymers based on vinyl pyrrolidone (VP) have been created incorporating features for improved performance. Initially VP was copolymerized with vinyl acetate (VA) to increase hydrophobicity and to improve high humidity hold. Derivitization with such monomers as dimethylaminopropylmethacrylate (DMAPMA) to improve flexibility and film smoothness as well as humidity resistance followed. Alkylated monomers imparted hydrophobicity, which improved mechanical durability under high humidity. Quaternization provided greater substantivity, especially from rinse-off applications.3, 4

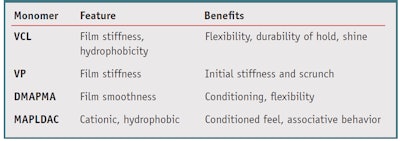

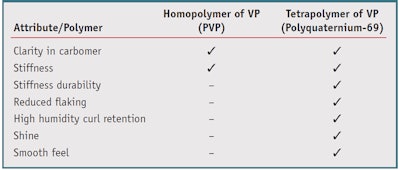

Terpolymers were made with not only the aforementioned class of monomers, but also with acrylic acid derivatives and vinylcaprolactam. An advanced styling polymer derived from VP homopolymer is the tetrapolymer polyquaternium-69. The structure of this polymer is illustrated in Figure 1 and structure-function relationships of the components are listed in Table 1.5 It can also be seen in Table 2 how the derivatization of VP adds important hair attributes that the VP polymer cannot achieve alone; besides film stiffness, the tetrapolymer provides stiffness under mechanical stress or durability of stiffness, high humidity curl retention, and reduction in flaking, to name a few.

An approach to making a VPtype polymer more hydrophobic is copolymerizing with hydrophobically modified acrylates (AA), as is evident in VP/acrylates/lauryl methacrylate copolymer;6 this structure is depicted in Figure 2. The VP and AA moieties of the polymer provide for the primary stiffness and water solubility properties of the resin. The hydrophobicity provides multifunctional benefits such as enhanced hold at high humidity, low tack and flaking, and association with hydophobically modified gellants.

VP has also been copolymerized with vinyl imidazole and its derivatives. An example of an advanced styling polymer in this case is VP/methacrylamide/ vinyl imidazole copolymer, which is reported to have good setting properties under high humidity conditions and low tack, yet to still preserve clarity in polyacrylate type thickeners.7 This structure is illustrated in Figure 3. Besides using VP as a basis to create advanced styling polymers, monomers from other chemical families have been used. These consist of acrylates, maleic anhydride, polyurethane and naturalbased polymers and their derivatives. They can be categorized into their respective chemical classes in order to help in organization and selection for specific applications.

Polymer Synergies

Polymer modification strategy is guided by the blending of different monomers to achieve a particular benefit or benefits. As mentioned above, stiffness, high hold in humid conditions, mechanical durability and gel clarity are important attributes. Also popular, based on consumer trends, are volume/body, shine, curl management, fiber alignment and anti-frizz effects. If a particular polymer with a blend of monomers cannot achieve a multibenefit effect, the formulator usually resorts to physically blending polymers together to achieve an additive effect, where one polymer can supplement another to overcome deficiencies. Consequently there are many styling products on the market where PVP is still used as the primary fixative resin but in combination with a secondary resin at a lower level to help with one or more hair attributes.

One strategy to obtain the correct blend of polymers for multifunctional benefits is to use an experimental mixture design technique. An example of this was demonstrated by Philbin et al.8 Polyvinylformamide and two viscosity grades of polyvinyl alcohol were blended at ratios specified by a design of experiment (DoE) computer program. After data collection of the key hair attributes and multiple regression analyses, the optimal range of ratios of the three polymers was identified to provide the best clarity of gel, curl compression, high humidity curl retention, and reduction in flaking compared to PVP. The identification of this “sweet spot” was an alternate way of obtaining the correct multifunctional benefit by using a resin blend instead of blending the appropriate monomers in a newly synthesized copolymer. The formulator can utilize this blending technique to not only achieve a full range of performance properties, but also to help with compatibility, reduce the cost of a formula by blending more expensive ingredients with other materials, or add properties to a polymer in which it is deficient.

When polymers become structurally more complex, applications research may reveal other features of the resinous film besides styling—either physical properties given to the formulation or new performance attributes. As an example, some fixative polymers have been found to have a dual role of providing fixative as well as rheological attributes. One such polymer is acrylic acid/VP cross-polymer. Like carbomers, it is based on cross-linked polyacrylic acid and it will form clear shear thinning gels that can suspend particles due to its yield value. Also, due to its copolymerization with VP, the polymer has hold properties.9 Another example is polyacrylate-14, which is a lightly cross-linked acrylate copolymer of C1–4 alky(meth)-acrylate, (meth)acrylic acid and a mixed hydrophobe package. This polymer can form clear shear thinning gels and add a host of hair styling benefits including high humidity resistance and hold, along with acceptable aesthetic properties such as no tack and low flaking.10 Dehydroxanthan gum, which also has fixative and rheological properties, has the advantage of being naturally derived and does not require neutralization.11 These three polymers are prime examples of how one can exploit all of the polymer’s features to yield multifunctional benefits.

Regulatory Influences

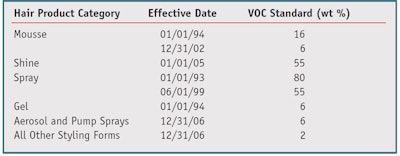

Regulatory changes are a driving force in product modification and adaptation especially with respect to polymer choices, propellant usage, solvents, packaging and components. The California Air Resource Board (CARB), for example, has been aggressive in reducing the levels of volatile organic compounds (VOC) in hair styling products since 1993 (see Table 3).12 Canadian authorities, the US Environmental Protection Agency (EPA), and regional US organizations and commissions such as the Ozone Transport Commission (OTC) have followed the CARB’s lead to some extent. Clean Air for Europe (CAFE) may have a future impact in the European Union (EU), though no specifics are available.

Regardless of the imposed change or limitation, the solution for compliance often requires more than a simple adjustment in solvent level or propellant type to maintain performance, aesthetics and compatibility. Current regulatory constraints focus primarily on VOCs, which are of particular concern due to their reactivity in the lower atmosphere that along with nitrogen oxides form ozone and contribute to smog creation. It is worth noting that VOC limits are currently mass-based, which means all equally regardless of their reactivity in the atmosphere. For example, in a 55% VOC hair spray, 55% w/w of the formula can be comprised of VOCs. The individual ingredients contributing to this amount are irrelevant as long as the mass requirement is no more than 55%. Another atmospheric environmental factor is Global Warming Potential (GWP), the measure of how much heat is trapped by a greenhouse gas in the upper atmosphere relative to carbon dioxide. The identified gases are carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons and sulphur hexafluoride. Currently there are no regulations in the United States limiting GWP gases in hair care products, though there is some activity in the European Union.

Aside from the product form, the target region and/or regions and their respective regulatory environments are a primary factor in hair product development. Solvent, propellant, component and polymeric choices must be made in concert to achieve a compatible and functional system. Understanding which ingredients are considered VOCs or have GWP implications and their interactions, compatibilities and impact on product performance is necessary. Common ingredients used in hair styling products that are excluded as VOCs, due to negligible photoreactivity in the lower atmosphere, include: acetone, methyl acetate, cyclopentasiloxane and hydrofluorocarbon 152a. Typical solvents in hair care products are water and ethanol, the latter of which is considered a VOC. Other solvents delivering enhanced functionality or finding application in more specialized products include methylal, isopropanol, aliphatic hydrocarbons, and as previously mentioned, methyl acetate and cyclopentasiloxane.

Packaging Considerations

In addition to system compatibility, it is necessary to ensure compatibility with components and packaging. There are two basic can types used in styling formulations, aluminum and steel. Although the choice of can is often based on aesthetics such as shape, size and appearance, the interaction of the system should be the primary focus. Often, aluminum can linings can be chosen based on the pH of the system;13 however, cationic surfactants or polymers along with propellant interactions may present incompatibilities. Dimethyl ether, for example, is only compatible with a polyamideimide lining.

Compatibility within tin-plated steel systems can also be controlled through pH maintenance but is dependent upon the amount of water contained and the other ingredients within the system. Inhibitors such as sodium benzoate, ammonium benzoate, cyclohexylamine ammonium benzoate, and combinations of borates and ammonium hydroxide are often employed.14, 15 Can corrosion screening methods are available and can be very useful in the selection of polymers, inhibitors and additives, as well as the resultant use levels.16, 17 Long-term stability testing of the final system should be performed over a series of time intervals and temperatures.

Additional package considerations include the valve material, gasket and wall thickness of the can used. Generally, it is good practice to use the same metal content for the valve as the can type. The gasket material of the valve should also be checked for compatibility with the propellants and solvents within the system to avoid possible clogging and/or leakage due to swelling, shrinking, or other potential issues. The pressure of the finished system at 54.5°C (130°F) must also be known in order to choose the appropriate can.

The delivery of the product is an important attribute both aesthetically and functionally. Valve selection in combination with the finished system must address sprayability, clogging and evacuation. In general, a 55% VOC hair spray includes 35–40% propellant, based on hydrofluorocarbon 152a low water or anhydrous, or dimethyl ether hydroalcoholic-based systems; propellant blends are used as well. Based on these propellant ratios, the viscosity of the concentrate of the formulation should generally not exceed 25 cP to provide for adequate breakup upon actuation. The polymer or polymers chosen will have a direct impact depending on the molecular weight and use levels. The use of surface active ingredients may aid in lowering solution viscosity as well as improve the wetting of the polymer film once applied to the hair.

The guiding principle in the development of an aerosol system is that there is a sensitive balance between performance, aesthetics and the physicochemical properties of the system, as well as the additional constraint of regulatory requirements. The complete aerosol package is a complex system involving not only multiple components and variables, but also their interaction. Keeping this formulation principle in mind, along with a firm knowledge of the ingredients employed in aerosol systems and options in componentry, the formulation chemist will find success in matching desired project profiles.

Assessing Performance

The basic properties of a polymer film can be studied by simply drawing a solution of the film down on a glass plate and letting it dry. The resultant film can be tested for properties such as clarity, hardness, adhesion to the glass surface and reactivity to water. Some of these properties can be translated to the behavior of the film on human hair. However, evaluation of these film properties and performance benefits on hair is more complex because it involves the added dimensions of film adhesion to the substrate and behavior of the fiber assembly due to film-fiber assembly interaction.

To test this added dimension of the polymer’s behavior on hair, the mechanical properties of polymertreated hair were studied using a texture analyzer on hair tresses formed into what Jachowicz described as “omega loops.”18–21 The physical features of the treated hair were characterized by such properties as stiffness, stiffness durability, durability at high humidity, elasticity and plasticity. Conclusions could then be made as to the benefits of polymer treatments to hair, especially with respect to styling. Examples of two stress-strain curves are depicted in Figure 4 demonstrating a brittle polymer vs. a polymer that is flexible in nature. The brittleness is indicated by the reduction in force as the probe of the texture analyzer continually depresses the polymer-treated omega loop. The elastic polymer portrays a very smooth force vs. distance curve, indicating the polymer and polymer-fiber bonds have not broken in not only the first pass of the probe but also, and most importantly, in subsequent cycles.20

Since the performance of a styling polymer is dependent on the polymer interacting with the hair fiber, it can be deduced that the adhesion of the polymer on the hair is as important a physical parameter as the polymer’s cohesive properties. The polymer therefore must have good adhesion to not just individual hairs but with the hair fiber assembly so it does not detach from the surface during stress. No doubt the polymeric film on an individual fiber contributes to the stylability of hair but it is the inter-fiber connections that provide for an exponential degree in stiffness properties. The polymer-hair fiber assembly structure is a composite, where the strength of the final system is not a mere addition of its components parts. Therefore both the physical properties of adhesion and cohesion are important for the fixative to have good performance.

The importance of considering both adhesive and cohesive properties in the stiffness of polymer-hair fiber assembly composites was demonstrated by Wade-Rafferty.22 The polymer under study in this case was a quaternized natural polymer-based on cassia gum with a range in charge densities. The stiffness of these polymers was measured on polymer-treated hair tresses using a texture analyzer with a three-point bending apparatus. It was found that the peak force was indirectly related to the charge density; i.e., the higher the number of quaternary groups on the molecular backbone of the natural polymer, the lower the stiffness. Rafferty concluded from this that the higher the charge density, the lower the cohesive strength of the polymer and thus the lower the stiffness.

Interestingly, the trend in stiffness for quaternized polymers reverses when tested at a higher humidity. Here, the lower-charged polymer becomes plasticized by the high humidity with a subsequent reduction in cohesion, and the higher adhesion of the higher charged density polymer becomes more discernible. This is a good example of how the polymer’s adhesion to hair and promotion of fiber-fiber linkages, along with cohesive properties of the polymer film, are important to consider.

Evaluation Techniques

Throughout the course of the product development process, various test methods are employed to substantiate efficacy. In early stages, instrumental techniques are used to screen for aesthetics and performance. As the process evolves, and if toxicological assessment has been achieved, then evaluation can commence on human panelists. Salon and consumer use studies are time-consuming and expensive, therefore product evaluation typically progresses from in vitro measurements and trained panel evaluations to screen and develop the formulation against its project profile. For in vivo testing, the project brief is referenced to determine the target market with respect to hair type/origin, degree of damage and hair length, as well as key attributes/claims, e.g., 24-hr hold, protects hair and enhances straightening, and volumizing.

Styling products are applied to hair during different stages of the styling process, thus it is important that the performance evaluations reflect the consumer/styling application. Successful development of the styling product has been achieved when the technical objectives have been met, the claims statistically substantiated, and the performance versus appropriate benchmarks is accepted by the consumer. When the consumer perceives the product as having the claimed benefit, market success of the product is greatly increased.23 Evaluation techniques used in the product development process are outlined in Figure 5. This is meant to provide a cross-section of the typical test methods employed without dwelling on details of test methodology.

Stiffness, flexibility and tack profile: These properties can be measured by a tensile meter such as a texture analyzer under various temperature and humidity conditions and to measure adhesive forces.18–20

High humidity curl retention: Although this is an old method, it is still used today for styling efficacy measurements. It can be adapted for products added to wet hair such as hair gels, and dry hair such as hair sprays. It also can be used to determine the initial curl droop from especially low VOC formulations. Curl retention measurements are taken periodically at intervals up to 24 hr for high hold claims.

Volume: Ring/radial compression methods have been used to measure hair body, in which volume is a key component. In this method, a hair tress is pulled through a ring of different radial dimensions and the force required is presumed to provide a measure of volume or body.24 Further, two advanced methods that have been developed include a controlled mechanical styling component employing the use of laser stereometry,25 and image analysis of two-dimensional spatial arrangements of tresses, mannequin heads or styles from live panelists.

Smoothness: Coefficient of friction of styling product films may be assessed using a slip peel tester, where the movement of a sled over a stationary styling polymer film measures force vs. distance and allows for the calculation of static and kinetic coefficient of friction. More recently, the atomic force microscope (AFM) has become an important tool for studying the micro-/ nano-scale surface architecture of styled human hair.

Shine: In assessing the finished style, shine or matte finish is a key claimed attribute. When testing shine, it is best to conduct the evaluation in a controlled light box where lighting is uniformly distributed and the source for light has several modes, such as daylight or fluorescent.

Thermal protection: Several methods have been developed to characterize thermal damage and to assess the protection imparted by styling treatments.26 Some methods include fiber fragmentation techniques, differential scanning calorimetry (DSC), spectrofluorimetry, FTIR image analysis, and surface techniques such as SEM and AFM.

Trained panel evaluations: In instrumental analysis, a single attribute is evaluated, and while this is objective and easier to quantify statistically, the overall properties are not captured. Tress testing, where a wide range of attributes can be evaluated in a single test, is one step closer to consumer evaluation. Hair attributes judged by a panel include such traits as shine, stiffness, stiffness durability, flaking, manageability and static fly-away. Ideally, panelists are calibrated to score based on a series of known controls so that the assessment of each attribute is more accurate.

Salon testing: When instrumental and trained panel assessments align with the desired attributes and the formulation has been deemed safe to test on human subjects, the process moves to in vivo evaluations with clinical salon testing. The benefit of salon testing is that the product is evaluated in its entirety; from the package, i.e., dispensing of the product, product form and distribution through hair, throughout the styling process including evaluations of the tack phase, ease of styling, compatibility with styling tools, and end result, i.e., stiffness or shine. Evaluations are typically half-head versus a control formulation that may be an internal or commercial benchmark. Full head evaluations may be used for new technology/product concept testing when there is no suitable benchmark.

Consumer home use testing: The last phase of the styling product evaluation is consumer use studies. Data collected up to this point from instrumental, trained panel and salon studies has been controlled with application dosage amount, environmental conditions and designed criteria for evaluation. This step is critical to reflect consumer opinion because results from trained panelists and instrumental analysis are often not the same as are perceived by the consumer, or attributes that have not been measured or evaluated in salon or lab tests are discovered as being key attributes for the consumer.27

Future Scope

Polymer science has seen considerable progress in the last two decades. In the future, the amalgamation of polymer science and other sciences such as colloidal and biotechnology will lead to novel composites. The distinction between product formats is becoming hazier; for example, conditioning treatments and styling products are bridging their respective gaps, thus more demand will be placed on rinseoff products to deliver benefits that are presently offered by leave-in systems. In addition, demands for unique and/ or novel product textures will challenge scientists to create product microstructures that deliver unique sensory and functional benefits.

Further, the personal care industry has seen growth in not only the number of methods to evaluate hair damage and the effects of cosmetic treatments, but also in their sophistication. Methods now map the topography of the surface of the cuticle, form a profile of chemical components throughout the cross-section of the fiber, and measure the micro-mechanical properties of polymeric resin on hair. These methods will illuminate not just the features of new polymers, but explain in fine detail the exact mechanism of how they work to provide advanced styling and conditioning benefits.

Acknowledgements: The authors would like to express their thanks to Millie Asencio, R&D department, Ashland Specialty, for her expert help with the manuscript.

References

- Polymers in Hair Care, Spray Technology and Marketing (1995)

- R Lochhead, The History of Polymers in Hair Care (1940–Present), Cosm & Toiletries 103 (1988)

- SC Johnson, Acetylene-Derived Polymers, Cosm & Toil 99 (1984)

- S Martiny, Acetylenic polymers for hair styling products, Intl J Cos Sci 24 125–134 (2002)

- R Rigoletto et al, A new fixative polymer with advanced styling benefits, Cosm Sci Tech (2007)

- R Rigoletto et al, Styleze 2000: A new fixative polymer for gels-Formulation and processing guide parts I and II, Soap & Cosmetic 7–9 (2001)

- C Wood and P Hoessel, Luviset Clear—A new styling polymer for crystal clear hair gels, Cosm Sci Tech (2004)

- M Philbin et al, Advances in hair styling technology for clear hair gels, IFSCC Journal (2010)

- J Albanese et al, Ultrathix P-100: A new multifunctional rheology modifier. Part one: Hair care, Cosm Sci Tech (2006)

- Fixate Plus Polymer, Noveon Technical Data Sheet TDS-331 (Oct 23, 2007)

- J Woodruff, Hair care 2009, SPC (Autumn 2009)

- Final regulation order—Regulation for reducing emissions from consumer products, California Air Resource Board, available at www.arb. ca.gov (Accessed Mar 13, 2012)

- Spray Technology and Marketing (2003)

- M Pfaffernoschke, Intl J for Aerosol, Spray and Packaging Technology (2005)

- DC Streuli and LC Foltis, Low VOC optimization for hair styling products, Spray Technology and Marketing (2004)

- J Dallal and CM Rocafort, Hair and Hair Care, Marcel Dekker, Inc, NY

- Consumer Reports 638 (1988)

- J Jachowicz and K Yao, Dynamic hair spray analysis. I. Instrumentation and preliminary results, J Soc Cosmet Chem 47 73–84 (Mar/Apr 1996)

- J Jachowicz and K Yao, Dynamic hair spray analysis. II. Effect of polymer, hair type and solvent composition, J Cosmet Sci 52 281–295 (Sep/Oct 2001)

- J Jachowicz and R McMullen, Mechanical analysis of elasticity and flexibility of vergin and polymer-treated hair fiber assemblies, J Cosmet Sci 53 345–361 (Nov/Dec 2002)

- J Jachowicz and J Smewing, Using texture analysis to substantiate hair care claims, Cosm & Toil 121(9) (Sep 2006)

- DW Rafferty et al, The mechanics of fixatives as explained by polymer composite principles, J Cosmet Sci 60 251–259 (Mar/Apr 2009)

- H Moskowitz, Consumer testing and evaluation of personal care products, in Cosmetic Science and Technology Series, vol. 14, CRC Press: NY (1996) pp 393–423

- Y Kamath and H-D Weigmann, J Soc Cosmet Chem 47 256–259 (1996)

- R McMullen, F Zisa and J Jachowicz, Measurements of hair volume by laser stereometry, J Cosmet Sc 60 171–185 (Mar/Apr 2009)

- Y Zhou Et al, The Effect of various cosmetic pretreatments on protecting hair from thermal damage by hot flat irons, J Cosmet Sci 62 265–282 (Mar/Apr 2011)

- L Aust, Cosmetic claims substantiation, in Cosmetic Science and Technology Series, vol. 18, CRC Press: NY (1997) pp 21–68