Lead and bismuth salts have been used for years in the United States to produce progressive hair dyeing solutions,1 which are more socially acceptable hair coloring processes than one-step dyes, and offer merchandising potential.

Due to its slow and gradual change, graying hair often goes unnoticed at first, until it eventually becomes obvious and pronounced. Once an individual becomes aware of their graying hair, they typically desire a hair color treatment but fear the attention that surrounds immediate and dramatic color restoration. This is particularly true of men, since women tend to begin coloring their hair at earlier stages of graying, thereby preventing and avoiding exposure to the public. In addition, target hair coloring, a specific and more radical color change, is considered a female cosmetic gesture. This process generally is only exercised by men when the truth can be kept secret.2

In an ideal world, the graying process could be reversed. The individual could control the reversal, reducing the number of years that the graying process takes and making it gradual so that a psychological advantage may be gained, in terms of peer awareness.

A gradual approach to coloring hair—a person’s best method in a non-ideal world—should be incomplete in its ultimate effect so that the process can be stopped with subsequent maintenance, or continued with successive and sequential color build-up; the result should be permanent and resist easy removal.

The application of the hair coloring product must be convenient and simple. Therefore, shampoo is considered the preferable choice of application.

Theory

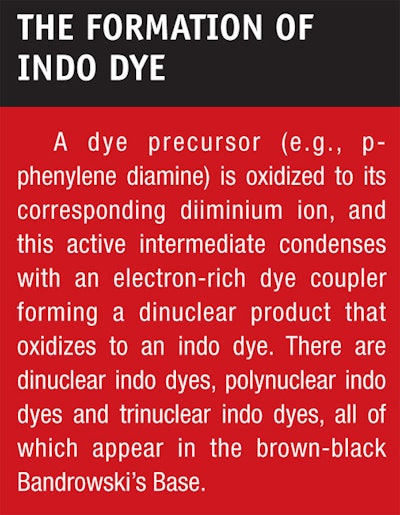

The most controllable color reaction on hair is that which employs oxidation-type dyes. According to Brown and Pohl,3 the oxidation process, in its simplest form, proceeds in three distinct steps. First, the primary intermediate is oxidized to a reactive imino compound. Second, this reactive imine couples with nucleophiles in the solution to give the dye precursors that are oxidized in the final step to the dye. This can be best demonstrated by the reaction of para phenylene diamine (p-Phenylenediamine) with an oxidizer to form Bandrowski’s Base (Figure 1).

It has been proposed 4 that p-Phenylenediamine diffuses into the hair fibers and is oxidized to diamine, which in turn condenses with p-Phenylenediamine to form Bandrowski’s Base, a brown-black indo dye.

The formation of Bandrowski’s Base is consistent with the following: The polymerization process of color bodies in the hair fiber depends on the concentration of dyes and oxidizing potential of the oxidizing agent. This seesaw effect can be advantageously exploited to give variations of color intensity, which are controllable by the use of pre-measured quantities of oxidizing agent. The oxidizing agent of choice is urea peroxide, since it can be tableted and/or solubilized in a mutual solvent such as glycerol for easy dispensing by an untrained individual. The color reaction would be as is shown in Figure 2. 5

Since color couplers do not produce colors by themselves when oxidized, but only in the presence of oxidized dye, a measurable control can be realized from adjustment in dye concentration. In addition, the adjustment of oxidation quantity can be appreciated as a second measure of possible control. These two variables in the reaction mechanism can together produce a product that suits the stated parameters.

In order to ascertain the feasibility of this method, two separate variables must be investigated. The first concerns the 5-min time period that the oxidation dyes take to work. All commercial hair dyes are formulated to operate between 30–45 min. This dyeing time would have been impractical for any potential marketing concept.

All commercial hair dyes are formulated to operate with equal parts of 6% hydrogen peroxide. That is, to every ounce of shampoo/color, an equal ounce of 6% hydrogen peroxide is added. This is determined to be a high concentration for practical purposes. Rather than a ratio of 1:1, it is deemed necessary to have a maximum ratio of approximately 1:0.17 because in the former case, there was potential for excessive skin staining, harsh color rendition and possible hair damage.

As an additional requirement, low levels of total dye are maintained. A subjective concentration of half the quantity of most oxidation hair dyes will be selected in order to avoid skin staining, harsh color rendition and hair damage.

Therefore, a range of 2–3% of dyes is chosen. In doing so, it is believed that the color uniformity associated with commercial hair dyes, which often gives an artificial appearance to the finished hair color, may be avoided.

Method

In order to test these premises, it was felt prudent to use a standard oxidation hair dye system. The variables were kept at a minimum without introducing uncertainties and a standard base formula was employed (Formula 1).

Due to the unpleasant odor of ammonium hydroxide, it could be replaced with a fixed alkali of similar partial ionization, such as monoethanolamine. The detergent system could be modified for better shampoo (foaming) performance by introducing salts of fatty alcohol sulfates. The formula for the oxidizing medium varied from the base formula (Formula 2).

Of course, hydrogen peroxide and its other salts can be considered for this application. The most important aspect of urea peroxide is its stability in the oxidizer formula.

A color shampoo treatment was made by mixing 1 oz of (Formula 3) (blonde) with 1g of Formula 2 (urea peroxide). Three hair swatches were placed in this color bath for 5 min at room temperature. The hair swatches were then removed and rinsed with lukewarm water until the rinse water ran clear.

The color results were barely perceptible in the first swatch. The two remaining swatches were next placed in a color bath containing 1 oz of blonde and 2 g of urea peroxide, again for 5 min at room temperature. After 5 min, the swatches were removed and rinsed. By visual assessment, the rendered color was almost twice the depth in the second phase.

Finally, the last hair swatch of the series was placed in a 1 oz color shampoo bath containing 4 g of urea peroxide for 5 min at room temperature. Again, the swatch was removed and rinsed. The rendered color was deeper than the result of phase two, and it was therefore observed that a progressive and linear relationship in color value existed between the three hair swatches.

Indeed, the color relationship appeared to be almost geometric in performance and controllable by concentration of oxidizing agent.

In order to confirm this hypothesis, another color of the opposite spectrum was employed—black (Formula 4).

The same series of experiments was repeated with the black color. It became immediately evident from the results of the second group of hair swatches that the same linear relationship in color rendition existed for the black color as for the blonde color. It is a notable fact that in both blonde and black color cases, the results show a pragmatic approach to a formulation system for a progressive hair color product.

Results

It is clear from the blonde and black color shampoo experiments that the following relationships exist to produce a progressive color rendition per color category:

• 1 oz of color plus 1 g of oxidizer yields barely perceptible color.

• 1 oz of color plus 2 g of oxidizer yields definite color.

• 1 oz of color plus 4 g of oxidizer yields target color.

This would be true in the four major categories of hair color: blonde, red, brown and black, as well as their subcategories.

Discussion

The results of the color shampoo tests are not intended to directly represent marketable items; they are to be considered only for their scientific value and as proof of a feasible concept. The desirability of a product that could overcome natural graying in sequential applications has been one of the long-standing goals in development of commercial hair dyes. The purpose of such a progressive color system is to minimize the attention surrounding such a marked change in appearance and avoid perceived embarrassment by the recipient.

Holmes6 has discussed the theoretical aspects of the diffusion of dye molecules into hair fibers and concludes that the mechanism can be explained by passage of a molecule across a porous barrier. In this dyeing system, the key ingredients—ammonia, water, hydroxyl ion, peroxide, p-Phenylenediamine, resorcinol and p-Aminophenol—are small molecules that can penetrate the hair fiber readily, where, within a designated time, they polymerize to form large molecules of predetermined color.

The suggested mechanism of increasing coloration on hair by increasing oxidation potential has shown an ability to satisfy marketing needs. The idea of varying the dye bath concentration with a fixed—as opposed to varying—amount of oxidizing agent, while a possibility, could potentially cause gross untidiness or an almost artificial- looking color rendition, which appears harsh together with skin staining and hair damage and likely would not be commercially feasible.

Product technology has always sparked new consumer interest in hair coloring. Those who had never considered coloring their hair before are now giving it a try, enticed by new product formulas and application types. Because it is easier to apply and requires less color commitment, a color shampoo method can be marketed to all groups and sexual categories as a low-risk, high satisfaction cosmetic accessory.

Oxidation dyes are permanent dyes in that they are not easily removed until the hair grows out at an approximate rate of one half-inch per month. Color shampoo makes use of this permanent property, which is not available in semi-permanent ionic dyes such as acid dyes and basic dyes, or metallic ingredients such as lead or bismuth salts.

The composition and dyeing conditions of oxidative hair dyes consist of the following: 7

1. Dye precursors, which form active intermediates;

2. Dye couplers, which condense with the active intermediates;

3. An oxidizing agent (usually a peroxide); and

4. the reactions are carried out at an alkaline pH.

The results of the above experiments are based on a preliminary investigation. Therefore, the discoveries found should be used to guide further research. The work proposed in this disclosure indicates rather succinctly that progressive dyeing is possible through control of the oxidizer moiety of oxidative dyes. It is for the researcher with general experience to bring this idea to a complete conclusion.

References

1. US Pat 4,583,986, Catalyzed Bismuth Dye System for Human Hair, H Lapidus and A Shansky (Apr 22, 1986)

2. Hair Colorants, Chapter 27 in Harry’s Cosmeticology, Seventh Edition, JB Wilkinson and RJ Moore, eds, New York: Chemical Publishing, (1980) pp 521-554

3. KC Brown and JF Corbett, The role of meta difunctional benzene derivatives in oxidative hair dyeing, II reactions with p-amino phenols, J Soc Cosmet Chem, 30(3), 191–211 (1979)

4. KC Brown and S Pohl, Permanent hair dyes, Soc Cosmet Chem Monograph, 1–10 (1996)

5. R Heald, Solvent Assissted Dyeing Systems, American Perfumer and Cosmetics, 78(40), 1–8 (1963)

6. HW Holmes, The Theoretical Aspects of the Diffusion of Dye Molecules Into Hair, J Soc Cosmet Chem, 15(20), 595 (1964)

7. CR Robbins, Chemical and Physical Behavior of Human Hair, New York: Van Nostrand Reinhold Co. (1979) pp 113