Microsphere refers to a spherical microparticle between 1 and 1,000 microns (μm) in diameter (see Figure 1). Also known as spheres, balls, beads or micro-balloons, microspheres are manufactured from a variety of raw materials. The most common types are solid and hollow glass or polymer microspheres, as well as ceramic. Each type is designed in different grades depending on the application and quality requirements. The quality of the microspheres ranges from monodispersed microspheres produced under tight specifications, to microsphere grades with variations in particle size and sphere uniformity.

Glass, polymer and ceramic microspheres are well-known in the cosmetics and personal care industry for advantages such as sensorial benefits and optical effects, among others.1 Their spherical shape and smooth surface create a low friction ball-bearing effect that gives formulations an elegant, silky feel. This ball-bearing effect promotes better blending on the skin and a more natural finish due to the enhanced slip, glide and omnidirectional spreadability, imparting a cream to powder texture. Outstanding roundness also provides lubrication during application, which enhances the tactile experience of a cosmetic product.

In addition to enhancing the feel and appearance of skin, the appropriate microspheres can minimize the appearance of fine lines and uneven skin tone. This is achieved due to microspheres’ ability to scatter light, an effect referred to as optical blurring or soft focus. Skin imperfections are visible due to high contrast. However, spherical particles have the capacity to optically reduce this contrast and hide imperfections on the skin surface by scattering or diffusing light. Since the microspheres optically blur lines and imperfections using light, the skin remains natural-looking.2

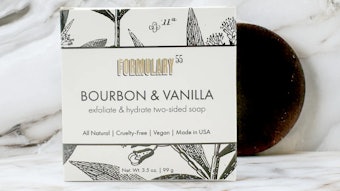

Microspheres are also used as gentle exfoliators in facial scrubs. Round particles are known to be less irritating to the skin than irregularly shaped, abrasive exfoliants with sharp edges such as apricot kernels and walnut shells. The roundness and smoothness of microspheres therefore makes them gentle and effective exfoliating agents to remove dead cells without harming the skin.3, 4 In addition, microspheres are commonly used as fillers/texture enhancers in pressed and loose powders, foundations, concealers, lipsticks, mascara, skin lotions and variety of other applications; a sample wrinkle and line minimizer is shown in Formula 1.

Colored Polyethylene Microspheres

A line of colored, solid polyethylene microspheres was recently developeda via a proprietary process to produce polymer microspheres that are smooth, highly spherical, non-soluble in water and most solvents, and that withstand temperatures of up to 100°C. These spheres can be manufactured with specific gravities from 0.96 g/cc to 1.3 g/cc, which provides for optimal suspension in a solution. Solid polymer microspheres incorporate pigments and additives to achieve colorful fillers that serve multiple functions in a cosmetic formula by acting as colorant, opacifier and texture enhancer simultaneously.

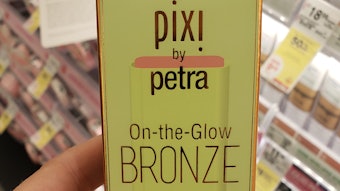

Color: As noted, solid colored microspheres add color to a cosmetic formula without the need for other pigments or dyes. Solid polyethylene microspheres can also be manufactured in most colors, including flesh tone, clear, gray, fluorescent (see Figure 2), glow-in-the-dark and multicolor, among others, which suggests several options for color effects as well as an array of color-matching possibilities (see Figure 3). The described polyethylene microspheresa are unique in that they can be color-matched to the requirements of a given product, and they can be used to add saturated color, a hint of color, or just a sparkle to a formula.

The use of colored microspheres simplifies cosmetic formulations by replacing pigments that are difficult to disperse and sometimes hazardous. Typically, pigments of particle sizes smaller than 1 μm are used for increased tint strength. However, powders of pigment particles in the submicron size range are difficult to work with because they tend to clump together and, as a result, do not disperse properly in solution. In addition, powders under 5 μm are considered respirable by OSHA because they are small enough to penetrate the nose, upper respiratory system and the lungs, which poses a health hazard for workers regularly exposed to the dust.

Colored microspheres therefore enable formulators to achieve saturated colors or desired color effects with larger particles, which are not respirable. In addition, they are designed as a free flowing dry powder, ensuring a simpler formulation process, and since larger microspheres tend not to agglomerate as easily as submicron pigments, the challenge of pressed powder agglomeration is greatly reduced.

Opacity: Solid polyethylene microspheres can be designed as transparent and invisible to the eye, partially translucent, or opaque, providing maximum hiding power. Generally, when light strikes an interface between two substances, some of the light is reflected, some is absorbed, some is scattered and the remainder is transmitted. An opaque substance transmits little if any light and therefore reflects, scatters or absorbs most of it. The opacity of the microspheres can be quantified in many ways, including viewing the spheres under a microscope with a backlight and measuring the reflectance of the monolayer spheres on white and black backgrounds.

Since opaque microspheres do not allow light to pass through (see Figure 4), this means that just a 50 μm monolayer of opaque polyethylene spheres will not transmit light, thus resulting in maximum hiding power in one light layer of makeup. Opaque microspheres are desired in color cosmetic products such as powder, concealer, blush, lipstick, eye shadow, nail polish and others, where uniform color and hiding power of the color beneath is desired.

In general, high levels of opacity become more difficult to achieve in microscopic particles because opacity is proportional to the thickness of the material. Due to the chemistry of glass, it is difficult to create opaque glass spheres. Most colored glass microspheres are made by attaching dyes to the surface of the particle and do not achieve significant opacity. Ceramic microspheres can be opaque but microspheres in a batch usually do not have the same level of opacity, with some being more opaque than others. The manufacturing process for the polyethylene microspheres described enables the incorporation of colorants and opacifiers inside the solid sphere, which ensures that spheres are produced with identical color and opacity.

Specific gravity: As noted, the specific gravity of polyethylene microspheresa can be adjusted to match the specific gravity of water or other external media. Particles that are heavier than the media they are dispersed in will settle at the bottom of the container over time. Particles that are lighter than the media will float to the top and accumulate on the surface. Matching the specific gravity of the microspheres to that of the base solution therefore creates a stable suspension of particles, ensuring uniform distribution in the product and preventing particles from settling out or collecting at the top of the container. This matching is achieved using proprietary additives incorporated into the polymer during the manufacturing process.

Electrostatic charge: Polyethylene microspheres can also be neutrally, positively or negatively charged, allowing formulators to design products that are attracted to or repelled from the skin. Human skin has a highly positive electrostatic charge. Since like charges repel and opposite charges attract, the charge of the cosmetic products can be manipulated to be more attracted to the skin, if the product is designed to be absorbed or remain for a long time, or less attracted to the skin if the product is designed to only remain for a short time on the skin and easily be wiped off. Charged microparticles also enable formulators to control how the various materials within a formula interact.

To create positive or negative charges, proprietary additives are embedded into each microsphere during the manufacturing process. This charge is permanent; it does not dissipate over time and cannot be grounded. The whole microsphere is charged and will respond to electric field. Further, dark-colored or black microspheres can be made magnetic or static-dissipative, and a black magnetic coating on a portion of the microsphere can be used to create functionalized hemispheres (see Figure 5)—i.e., magnetic half-shells that can be manipulated to rotate microspheres with an electromagnetic field.

The orientation of bichromal microspheres in color cosmetics requires further exploration but is an area of potential future development. This trait could potentially be used for creating interesting color-changing effects, to improve effective blending with skin color, or even to provide light-reflecting effects for younger looking skin.

Safety and Ecological Considerations

Eco-friendly manufacturing: Since polyethylene is a thermoplastic material, it can be re-melted without losing its properties. Microspheres that do not meet the particle size requirements are recycled back into the manufacturing process, eliminating waste. In addition, the manufacturing process uses no solvents and does not generate volatiles; as a result, no hazardous materials are released into the environment as a by-product of the manufacturing process.

Safety of polyethylene in cosmetics: The Cosmetic Ingredient Review (CIR) Expert Panel has deemed polyethylene safe for use in cosmetics and personal care products. In addition, the CIR noted that the large molecular size of polyethylene polymers used in cosmetics and personal care products was not anticipated to absorb into the dermis to a significant extent, which would thus limit systemic exposure to polyethylene.5 Also, the US Food and Drug Administration (FDA) allows polyethylene for use as food additive, provided its molecular weight is between 2,000 and 21,000.6 Furthermore, safety tests of cosmetic-grade polyethylene have consistently failed to identify any toxicity. Polyethylene may also be used in cosmetics and personal care products marketed in Europe, according to the general provisions of the Cosmetics Directive of the European Union.7, 8

Polyethylene Myths

Several recent non-technical articles9, 10 have suggested that polyethylene exfoliants could destroy marine life and remain in the environment a thousand years from now. Despite this speculation on the subject, no technical data exists to support these statements and in many cases, these myths are generated by companies distributing natural ingredients and products. Ecotoxicological data on analogous polymeric materials has demonstrated that low molecular weight polyethylene materials exhibit low aquatic toxicity to fish, algae and daphnia. Classification, according to German Umweltbundesamt, Germany’s central federal authority on environmental matters, is nicht wassergefährdend (NWG), or non-hazardous to waters. In fact, under OECD guidelines, this material is classified as an inherently biodegradable material. In addition, the volume of these microspheres used in cosmetics and personal care is small and most of the particles are expected to be removed during sewage treatment. And polyethylene is unlikely to bioaccumulate due to its large polymeric nature and insolubility in water.

Formulating with Microspheres

It is important that formulators select the right microsphere for the intended application. The defining factors become specific gravity, melting point, solvent resistance, crush strength, colors, additives and specific customization requirements. Detailed knowledge of the application, the technical judgment of scientists and engineers on the project, and sometimes simple trial and error are often relied upon to select the right microsphere for the job. Questions to consider include: What is the maximum temperature the formulation must withstand? Polyethylene microspheres are usually stable up to 100°C but glass microspheres withstand 500°C and higher. Also, what is the density/specific gravity requirement? As noted, if the microspheres must be suspended, matching the specific gravity of the particle and the solution might become a critical factor. Solid glass and ceramic microspheres have specific gravities greater than 2g/cc; however, polyethylene microspheres are available in specific gravities of 0.96g/cc to 1.3g/cc, close to that of water.

Another aspect to consider is: Will the microspheres be exposed to strong mechanical pressures? If the microspheres will go through an aggressive mechanical process, solid glass microspheres may be required since hollow glass or polymer microspheres could be crushed. Also, the color of the microspheres—i.e., colored, opaque or clear—is an important aspect. Since creating an opaque glass microsphere is nearly impossible, colored polyethylene microspheres are preferred for high color, opacity and superior coverage applications. However, glass microspheres are preferable if maximum clarity of the sphere is desired, for example, for soft-focus effects.

What particle size distribution is acceptable? Typically, monodisperse microspheres are the most desirable but also the most expensive. In general, the wider the particle size distribution, the more affordable the spheres. The requirements of each unique formulation must be investigated to find the most economical solution. While high quality microspheres tend to be more expensive, some lower-cost microspheres may have limitations to watch for, such as poor uniformity or consistency between batches, wide particle size distribution, dust, debris, and oblong and non-spherical particles, which will negatively impact the texture, appearance and feel of the finished product.

It is also important for the formulator to work with a supplier that thoroughly screens microspheres to prevent dust, debris and non-spherical microparticles. Depending upon the requirements of the formulation, the specification on the maximum amount of unacceptable particles must be determined and communicated to the supplier. For example, with luxury cosmetic applications, most formulators will look for high quality identical polymer spheres with excellent uniformity.

Conclusion

Ultimately, consumers will decide whether they prefer cosmetic products with exclusively natural ingredients or those incorporating synthetic materials such as polyethylene microspheres, which provide many advantages and functionalities. High quality solid polyethylene microspheres are now commercially available in a wide variety of colors and with controlled opacity, specific gravity, particle size distribution and even electrostatic charge, which presents more possibilities for interesting uses in cosmetic formulations. Moreover, new manufacturing processes have enabled the customization of the solid polyethylene microspheres to each cosmetic product’s unique specifications. Solid polymer spheres incorporate colorants and additives to achieve colorful fillers that serve multiple functions in a cosmetic formula by acting as colorants, opacifiers and texture enhancers at the same time.

References

Send e-mail to [email protected].

- AO Barel, M Paye and HI Maibach, Skin care products, in Handbook of Cosmetic Science and Technology, Third Edition, Informa HealthCare USA, Inc: New York, NY ch 34 (2007)

- P Delrieu and Y Shao, In vitro Method for Quantification of Soft Focus Effect of Particulates, Kobo, NYSCC Scientific Meeting, New York (Dec 8-9, 2005)

- M Houston, MD, How to Help Restore Your Youthful Appearance, Hypertension Institute and Vascular Biology, Saint Thomas Medial Group (Mar 30, 2009)

- D Grose, Importance of Skin Exfoliation, available at http://blog.asapskinproducts.com/2008/12/importance-of-skin-exfoliation.html (accessed Feb 11, 2010)

- Final Report on the Safety Assessment of Polyethylene, Intl J of Toxicol 26(1) suppl, 115-127 (2007)

- Food Additives Permitted for Consumption, FDA Web site, available at www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=172.615&SearchTerm=polyethylene (accessed Feb 10, 2010)

- Final Report on the Safety Assessment of Polyethylene, Intl J of Toxicol 26(1) suppl, 115-127 (2007)

- Consolidated Text of the Cometics Directive, available at http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:1976L0768:20080424:en:PDF (accessed Feb 10, 2010)

- H Rosner, Scrubbing Out Sea Life, available at www.slate.com/id/2193693/ (accessed Feb 11, 2010)

- J Layton, Are my bath habits destroying marine ecology? available at http://science.howstuffworks.com/bath-habit-marine-ecology.htm (accessed Feb 11, 2010)