Cosmetic products composed of natural ingredients have been gaining popularity for some time. In relation, commercial body and dusting powders containing natural starches, e.g., corn, potato, rice and tapioca, have been launched, as several patents reveal.1, 2 Another natural ingredient for application in powder products can be found in the wetland forests of southern Thailand, where sago palms (Metroxylon sagu Rottb.) are plentiful.

Sago palms can be harvested at anywhere from 7 to 15 years’ maturity prior to their flowering, at which point they produce fruit and perish. When harvested, their piths are filled with a fine, white, powdery starch that is nearly pure carbohydrate.3,4 This sago starch can be used as the main component in perfumed and cooling body power formulations, as will be shown here. Additional benefits of sago starch are its biodegradable properties, which reduce respiratory risk potential from accidental inhalation. Also, the use of sago starch can further support local wetland forest communities, thus promoting sustainability of this natural resource.

The objective of the present study was to examine the physicochemical properties of sago starch and sago starch-containing body powders to determine whether they possess skin irritation potential, and to characterize their properties according to the Thai Industrial Standards (TIS) for Cosmetics: Skin Powders (TIS 443-2525). The authors also investigated consumer satisfaction of sago starch-containing body powders by comparing prepared samples with two commercial perfumed and cooling body powders.

Preparation of Starch and Powders

Two sago palms, aged respectively 8 and 15 years, were harvested from Nakhon Si Thammarat Province in Thailand. Sago starch was produced from the palms by the traditional method: first, splitting the trunk, removing the pith, and crushing and kneading the pith with water to release the starch; then screening the starch through a cloth filter to separate the starch from the fibrous residue. The raw starch suspension was collected in a settling container and washed with water until a white starch was obtained. Finally, the starch was placed in an oven at 50°C until completely dry.

Perfumed and cooling body powders were prepared, comprised of sago starch as the main component (60% w/w) and talcum, light kaolin, zinc oxide and perfume, mixed in appropriate amounts using a blender. In the cooling body powders, 1% menthol and 1.5% camphor were combined for a eutectic mixture, then added to the formula as cooling agents. These cooling agents are acceptable under the TIS 152-2539 general specification.5

The fragrances used in the perfumed and cooling body powders were sweet and spicy, respectively. All chemicals included in the powder formulations were pharmaceutical grade and used without further modification. Each powder type was assessed via a primary perception survey and the most admirable formulations, as rated by the assessors, were chosen for further examination. The obtained mixtures were screened through a sieve with a 150-micron aperture and packed in plastic powder containers.

Physicochemical Properties

Each sample’s particle size and surface morphology was measured in triplicate by laser diffractiona. The samples were coated with a thin layer of gold for observation using a scanning electron microscope (SEM)b at 1000x magnification (see Figure 1). Applying gold or platinum to a sample allows researchers to hit the samples with the SEM’s electron beam to obtain their conductivity properties. Secondary electrons are knocked loose from the samples’ surfaces, and a detector then counts these electrons and sends signals to an amplifier to build up an image of the electrons emitted from each spot on the samples.

The roundness index of the sago starch, indicating the ease with which a sample rolls across the skin’s surface, is calculated by dividing particle length by width. These parameters were measured under an optical microscopec with an ocular scale calibrated with an objective micrometer. Particles are spherical when their roundness index is calculated as being equal or close to 1; if the roundness index is higher than 1, the particles are oval. In this case, the particles were oval-shaped, indicating the need to include other ingredients in the formulation to improve their slip on the skin—for instance, talcum. This factor is described in more detail below.

The bulk density of the samples was measured in triplicate by the three-tap method.6 A powder sample of approximately 20 mL was introduced into a 100-mL graduated cylinder. The cylinder was placed on a jolting apparatusd and tapped at 2-sec intervals onto a hard surface three times from a height of 1 in. The final volume was defined as the bulk volume. The bulk density was calculated as the mass of the sample divided by the bulk volume.

The flowability of the samples also was investigated by measuring the angle of repose, or α, in triplicate.7 The bottom of a glass funnel was positioned on a stand above the center of a fixed base (radius = r) with a fixed height. Each sample was poured to flow through the funnel’s orifice. A conical pile of discharged sample was formed on the base and its height (h) was measured for calculating the angle of repose as follows:

tan(α) = h/r Eq. 1

The apparent pH of the samples, 10% suspensions of the powders in distilled water, was measured in triplicate by a pH metere at 25°C. To determine their water and oil absorption, 5 g of each sample were titrated dropwise with water and mineral oil, respectively, until a damp mass was observed. The titration was carried out in triplicate.

The protein amount in the samples was investigated using a bicinchoninic acid (BCA) protein assay.8 The excess sago starch (3 g) was vigorously mixed with 3 mL of distilled water using a vortex mixer. Each mixture was allowed to reach equilibrium at room temperature for 3 hr. Afterwards, the mixtures were centrifugedf at 4000 rpm for 5 min. The supernatant (0.1 mL) was added to

2 mL of a 50:1 mixture of bicinchoninic acid solution and copper (II) sulfate pentahydrate (4%) and incubated for 2 hr at room temperature, at which point the reaction formed a purple-colored product.

The obtained samples were measured for absorbance by a UV-visible spectrometerg at 562 nm. The protein amount in the sample was calculated by a calibration curve comparing absorbance versus bovine serum albumin concentration. Validation of the method was performed to ensure that the calibration curve between 100 and 800 μg/mL of aqueous bovine serum albumin solution (standard protein solution) was in the linearity range. The experiment was carried out in triplicate.

Skin Irritation Test

Ten healthy volunteers, ages 22–25, participated in a human skin irritation test. The participants were briefed and gave their informed written consent. Two areas were targeted on their left lateral arms; on the first area, 0.2 g of the cooling sago starch-containing body powder was applied and the second area was left untreated to serve as a control. Both areas were covered with 2.5 x 2.5-cm2 gauze patches. On the right lateral arms, a 0.2 g sample of sago starch and a separate 0.2 g sample of perfumed sago starch-containing body powder were applied; again, both were covered with 2.5 x 2.5-cm2 gauze patches. Each area tested on the same arm was approximately 6 cm away from the other and the patches were fixed with non-allergic adhesive tape.

After 6 hr, the test specimens were washed off by tap water. Subsequently, the tested areas were photographed and compared with their initial appearance. Afterwards, the volunteers returned so that researchers could observe changes in the skin at days 2 and 3. This study was carried out with approval from the Ethics Committee of the Faculty of Pharmaceutical Sciences at Prince of Songkla University in Thailand.

TIS 443-2525: Specific Properties

The scores of specific properties—i.e., slip, covering power, adhesiveness, absorbency, bloom and spreading power—were determined by six independent referees via a blind test. Each referee, while untrained, was informed about each property as defined9 by TIS 443-2525 before performing the test and received samples of: sago starch from an 8-year-old palm, sago starch from a 15-year-old palm, perfumed sago starch-containing body powder, cooling sago starch-containing body powder, talcum, two commercial perfumed body powders and two commercial cooling body powders. All samples were labeled with random codes. After each sample was applied, the referee scored its specific properties according to TIS 443-2525, depending on their opinion. Scoring was conducted based on five ranges of satisfaction level; i.e., very poor (score = 0–30), poor (score = 31–54), fair (score = 55–74), good (score = 75–90) and excellent (score = 91–100).

Consumer Satisfaction

Consumer satisfaction with sago starch-containing body powders was investigated using questionnaires. Individuals were invited to try sago starch-containing powders on their hands and arms, after which they rated their fineness, slip, adhesion, odor and freshness (for the cooling powder) on a scale of 1–5; very poor (score = 1), poor (score = 2), fair (score = 3), good (score = 4) and excellent (score = 5).

Results and Discussion

Sago starch from palms of different ages: The visual appearance of raw sago starch obtained from sago palms aged 8 and 15 years was identical; i.e., a fine and white powder. The particles of both sources were identical as well, and were oval-shaped when viewed by SEM (see Figure 1). The basic physicochemical properties including size, roundness index, bulk density, angle of repose, pH and amount of protein content also were insignificantly different (p > 0.05), as shown in Table 1.

In addition, the protein amount in sago starch was too low to cause skin allergy—the average protein amounts were 0.03% and 0.05% for sago starch aged 8 and 15 years, respectively. No skin irritation was observed in the human volunteers. Therefore, sago starch from either source could be used in body powder formulations.

It should be noted that the oval shape of the particles may impart a low degree of slip on the skin. Therefore, it is recommended that talcum, light kaolin and zinc oxide in appropriated amounts be added to formulations to overcome this problem and to improve product quality. Talcum or talc is a hydrated magnesium silicate possessing a high level of spreadability or slip yet a low covering power. Kaolin provides good absorbency while zinc oxide has astringent and slightly disinfectant effects, thus offering skin protection.10

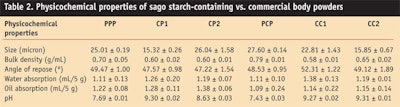

Properties of sago starch-containing powders: The physicochemical properties of sago starch-containing body powders compared with their commercial counterparts are shown in Table 2. Although the particle size of the prepared perfumed powder (PPP) was larger than the first commercial powder (CP1)

(p < 0.05), it was insignificantly different than a second commercial powder (CP2) (p > 0.05). For cooling powders, particles of the prepared cooling powders (PCP) were significantly larger than two commercial cooling powders (CC1 and CC2) (p < 0.05); however, the size difference was only in the range of 3–11 microns. Thus, the overall size of the prepared powders was not evidently different from the commercial powders.

The bulk density of the prepared powders was significantly higher than the commercial powders (p < 0.05) due to the density of the sago starch (0.80–0.89 g/cm3, see Table 1), which was quite high. The angle of repose of all studied perfumed powders was insignificantly different (p > 0.05); however, the PCP measured significantly smaller than the CC1 (p < 0.05) while it was insignificantly different from that of the CC2 (p > 0.05). Therefore, it could be assumed that the flowability of the prepared and commercial powders was not different.

An insignificant difference (p > 0.05) also was found in the water and oil absorption studies. Perfumed and cooling sago starch-containing body powders possesed an average pH of 7.69 and 7.43, respectively, and the TIS 443-2525 indicates that body powders should measure in the range of 5.5–10.9

The particle shapes of prepared vs. commercial powders were different, as shown in Figure 2 and Figure 3. In the prepared powders, sago starch was used as the main component and therefore, the oval structure was more prominent under SEM. However, since the commercial powders primarily contain talcum, a sheet- or flattened-shaped structure mainly was observed under SEM.

Skin irritation: No skin irritation from sago starch or sago starch-containing body powders, which were applied for 6 hr to the arms of volunteers, and no skin changes—i.e., redness, itching, fluid-filled bumps or blisters—were observed during the studies.

Properties according to TIS 443-2525: Scores of the raw sago starch from both sources for specific properties including slip, covering power, adhesiveness, absorbency, bloom and spreading power, according to TIS 443-2525, were insignificantly different (p > 0.05), as shown in Table 3. As expected, the scores of the prepared powders were lower than those of the commercial powders since talcum possesses a higher degree of the specified properties than sago starch. However, the scores of the prepared powders registered higher than the raw sago starch and achieved good ratings. Specifically, the average score for slip was greater than 70% for both formulations, indicating passing results for TIS stipulations of body powders.9

Therefore, it was deemed highly feasible and within acceptable ranges to use sago starch in the preparation of body powders. The scores for the other properties also were high (see Table 3), implying the potential to adapt the formulation of perfumed sago starch-containing body powder to loose face powders.9 Moreover, starch in face powders can provide bloom and a smooth surface on skin.10

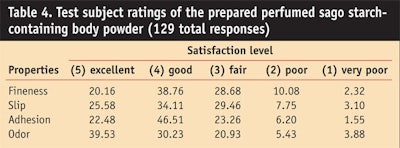

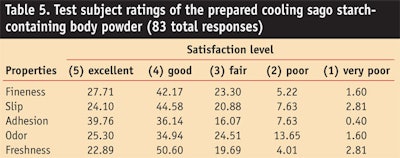

Consumer satisfaction: Consumer responses to sago starch-containing body powders were gathered from the 129 and 83 questionnaires administered for perfumed and cooling powders, respectively, indicating most customers were satisfied with both products, as is shown in Table 4 and Table 5.

Conclusions

In the present study, sago palms ages 8 and 15 years yielded sago starch with physicochemical properties identical to one another. The physicochemical properties of sago starch-containing body powders were found to be similar to commercially available perfumed and cooling body powders. In addition, the prepared sago starch and sago starch-containing powders did not cause skin irritation. The specific properties of the prepared powders were acceptable according to TIS 443-2525; in addition, consumers rated sago starch-containing body powders as satisfactory.

Therefore, the researchers conclude that sago starch can be used as the main component in perfumed and cooling body powders, thus fulfilling the need for natural, sustainable ingredients for cosmetic formulations.

References

1. US Pat 4,568,539, Body powder compositions, WH Ashton, RS Russell and DC Zajac, assigned to Johnson & Johnson Baby Products Co (Feb 4, 1986)

2. US Pat 6,143,285, Body powder composition, JR Howard, assigned to Combe Inc (Nov 7, 2000)

3. M Flach, Sago palm Metroxylon sagu Rottb.: Promoting the conservation and use of underutilized and neglected crops, Rome: Institute of Plant Genetics and Crop Plant Research (1997)

4. S Abd-aziz, Sago starch and its utilization, J Biosci Bioeng 94 526–529 (2002)

5. TIS 152-2539, Cosmetics: General specification, Bangkok: Thai Industrial Standards Institute (1996)

6. A Martin, Physical Pharmacy, PA: Lea and Febiger (1993)

7. The United States Pharmacopeia 30 and the National Formulary 25 (USP 30 and NF 25), MD: The United States Pharmacopeial Convention (2007)

8. PK Smith et al, Measurement of protein using bicinchoninic acid, Anal Biochem 150, 76–85 (1985)

9. TIS 443-2525 (in Thai), Cosmetics: Skin powders, Bangkok: Thai Industrial Standards Institute (1982)

10. ML Schlossman, Decorative products, Handbook of Cosmetic Science and Technology, chp 54, AO Barel, M Paye and HI Maibach, eds, New York: Marcel Dekker (2001) 645–683