Underlying the increasing debate among photoprotection chemists, regulatory bodies and end consumers around the effectiveness and safety of sunscreen ingredients is the assumption that in vitro testing for sun care is accurate and undifferentiated among the world’s development laboratories. In fact, this is not the case.

Sunscreen works by “hiding our skin” from the sun’s UV radiation. It is common sense that a sunscreen’s hiding power is dependent on coverage thickness. If you have ever attempted to paint a wall, you can appreciate that paint’s power to hide is related to consistent coverage thickness rather than the total weight of paint piled on the wall. Therefore, if a testing method cannot guarantee a reproducible level of thickness, the results can vary widely. Significantly, the most common testing devices prescribe the amount of sunscreen used, not its thickness.

Further, common sunscreen testing platforms use a substrate that has been purposely roughened to mimic human skin—but human skin is a complex structure that is not easily reproduced. Instead of mirroring human skin, the roughened testing substrates make accurately quantifying sunscreen film thickness impossible.

Many have attempted to create more reliable alternatives for sunscreen testing. One laboratory recently proposed robot-like machinery that allows testers to move away from simply rubbing material samples on substrates with their fingers. But even using robot arms, rubbing samples on substrates still cannot provide precise and known thickness. Without reproducibility and reliability, there can be no meaningful correlation between in vivo results. This current method is, at best, an artistic process rather than a scientific one.

Hallstar’s response to the need for more scientific in vitro photoprotection testing was to develop Solasure™, a brand-new full-solution platform for both pre- and post-irradiation performance testing that is now available for purchase. The differences between Solasure™ and the common testing method are extensive in ways that have the most impact on reproducibility and reliability:

- The innovative polished quartz substrate of closely controlled thickness (1200 μm) allows for precise, reproducible, and known sunscreen thickness by avoiding the impact of roughness on film thickness.

- Patented film deposition mechanics enable precise control of sunscreen deposition and the associated film thickness, guaranteeing a uniform and known thickness layer of testing sample.

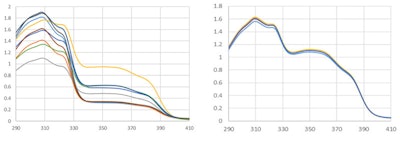

- Adjustable application sample amount can guarantee perfect absorbance in 290-400 nm range, thus maximizing the sensitivity of the UV spectrophotometer used for sun protection measurement.

- A unique dilution system reduces operational standard deviation without influencing testing results.

In addition, Solasure™ is cost-effective and very easy-to-use. View the video below of Solasure™ in action:

The new Solasure™ delivers a reproducible, quantifiable, cost-effective and easy-to-use sunscreen testing method, providing both formulators and end consumers with the confidence they deserve – confidence that their products’ perceived actual performance will correspond to the efficacy claimed.

The new Solasure™ delivers a reproducible, quantifiable, cost-effective and easy-to-use sunscreen testing method, providing both formulators and end consumers with the confidence they deserve – confidence that their products’ perceived actual performance will correspond to the efficacy claimed.Do you want to learn more about the Solasure™ Sunscreen Testing Platform? Contact Hallstar Beauty at [email protected].

Disclaimer:

The above paid-for content was produced by and posted on behalf of the Sponsor. Content provided is generated solely by the Sponsor or its affiliates, and it is the Sponsor’s responsibility for the accuracy, completeness and validity of all information included. Cosmetics & Toiletries takes steps to ensure that you will not confuse sponsored content with content produced by Cosmetics & Toiletries and governed by its editorial policy.

!['[Sunscreen] developers will be able to innovate more efficiently while maintaining high standards of quality and safety for consumers.'](https://img.cosmeticsandtoiletries.com/files/base/allured/all/image/2024/06/woman_outside_using_sunscreen_on_face_ISO_test_standards_AdobeStock_783608310.66678a92029d9.png?auto=format%2Ccompress&fit=crop&h=191&q=70&rect=62%2C0%2C2135%2C1200&w=340)