In today’s ultra-competitive personal care market, developers of personal care products must be at the forefront of technology and innovation to meet consumer demand. In the hair care market, as elsewhere, manufacturers with brands that fulfill customer needs are more likely to succeed in a crowded marketplace. To help meet this challenge, marketers seek solutions that differentiate their products, while giving multiple benefits from a single raw material technology. Multifunctional ingredients like silicones allow product manufacturers to simplify formulations while maintaining or improving product performance.

Silicones are one family of materials that help meet changing consumer needs. They have been important ingredients in hair care products since the 1950s, first appearing in hair sprays to lubricate nozzles and help keep them from blocking. In the 1970s, the hair conditioning properties of silicones began to play a significant role in products such as colorants, permanents and conditioners. Because bleached hair is easily damaged, many products designed to treat it depend on the conditioning properties of silicones. Silicones first appeared in shampoos in the 1980s, and played a major role in the development of two-in-one shampoos in the 1990s.

Today, these versatile ingredients are available as fluids, emulsions, resins, elastomers, waxes and blends. Their long history of use in hair care is due to benefits such as conditioning, shine, manageability, improved wet and dry combing and reduced fly-away. The newest silicone technologies also offer heat and color protection, provide body, improve straightening and impart flexible styling properties. This article reviews some novel properties and traditional conditioning functions of silicone materials for hair care applications.

Multifunctional Conditioning Agents

Hair damage can result from a number of environmental and chemical factors. In addition, frequent use of hair dryers and heated curling or straightening appliances contributes significantly to hair damage. Frictional forces of shampooing, brushing, frequent washing, towel drying and hair ties, combined with poor general health and diet, can have a compounded effect on the level of hair damage and the resulting appearance and feel of hair.

Proper conditioning can help protect hair from further damage and maintain a more healthy appearance. While damaged hair typically requires intensive conditioning, normal hair may require only light conditioning. The chemical structure of silicones and addition of functionality allow for a variety of materials that can meet hair conditioning needs.

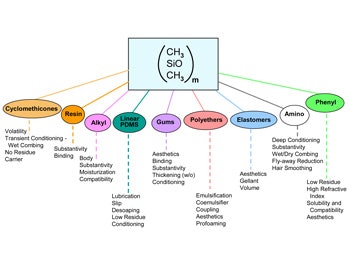

In addition to their role as conditioning agents, a number of silicone materials have multifunctional properties in hair care formulations. These materials range from basic cyclic or linear polydimethylsiloxane (PDMS) to polyether- and amino-based fluids and silicone resins. Figure 1 shows some of the families of silicone materials used in hair care applications and their functions.

Figure 1. Functions of silicones in hair care products.

Linear PDMS, also known as dimethicone, illustrates the basic structure of silicone, based on a backbone of Si-O groups with methyl pendants. It is available in a range of molecular weights and viscosities, and it is commonly used in hair care products to reduce combing force, add slip, impart a soft and dry feel, and add shine. PDMS gives a lubricating feel without greasiness or tackiness, and it has a desoaping effect on formulations.

The solubility parameters of PDMS are significantly different from those of water and many organic materials. PDMS polymers are highly water resistant, and except for certain low molecular weight species, they are incompatible with organic ingredients. The solubility characteristics of these materials can contribute to barrier effects and substantivity; the same properties make them effective agents in reducing the tackiness of formulations.

PDMS is typically used in opaque products, where it can be emulsified to provide increased formulation flexibility. Various viscosities of PDMS can be blended to provide specific formulation attributes such as evaporation rates, spreading qualities and sensory benefits.

Cyclic polydimethylsiloxanes or cyclomethicone fluids are characterized by ring structures typically containing three to six Si-O groups per ring. They reduce wet combing force and provide transient gloss to hair, without leaving residue or buildup. Because of their volatility, the effects of cyclomethicones are transient, a significant advantage in products designed for daily use. They help decrease drying time, which is helpful because the ongoing combination of combing and dryer heat are damaging to hair. Volatility also allows these materials to be used as carriers to facilitate deposition and spreading of active ingredients. Cyclomethicone fluids are compatible with a wider variety of ingredients than linear PDMS, and they can serve as good carriers for high molecular weight silicones that would otherwise be difficult to handle.

Silicone gum/fluid blends are composed of very high molecular weight PDMS supplied in low to medium viscosity linear PDMS fluid or cyclics for ease of formulation and improved compatibility. These materials offer a high level of substantive conditioning while imparting a soft, dry and lubricious feel to hair. They can also be used for their thickening effect in water-and-oil systems.

Phenyl trimethicone is based on linear PDMS with the addition of phenyl groups. The result is a higher refractive index, which is used to increase apparent shine on hair, typically in styling products or cuticle coats. Phenyl trimethicone adds softness with low residue and exhibits greater compatibility with organic ingredients for ease of formulation.

Amodimethicone fluids are recognized for their ability to provide deep conditioning. They are typically based on the replacement of some methyl groups on PDMS with primary and secondary amine groups. This amine functionality results in attraction to the negative, proteinaceous surface of hair followed by cross-linking to form a substantive film, a mechanism that can be used to provide targeted deposition without buildup.

Because of their larger organic groups, amodimethicone fluids can be easier to emulsify into surfactant systems, and they can be useful for making clear shampoos. They can also be used in rinse-off conditioners, semi-permanent and permanent colorants and leave-in conditioning treatments (e.g., detanglers, cuticle coats, hot oils, hair masks and mousses). In addition to softness, smoothness, reduced fly-away and faster drying time, amodimethicone fluids can be formulated to provide color protection for dyed hair and thermal protection from excessive heat from hair dryers, curling irons and other styling devices.

Alkylmethicones are based on the replacement of some methyl groups on PDMS with alkyl chains, resulting in a family of silicone-hydrocarbon hybrids. With variations in viscosities, melt temperatures and rheological characteristics, these materials can help overcome some of the issues related to incompatibility of PDMS with organic materials and water. Alkylmethicones also offer improvements in substantivity and moisturization. They can be used in water-in-oil emulsions to add body and aid stability without contributing negative aesthetics.

Silicone polyethers are a family of water-soluble or water- and alcohol-soluble silicone materials that can be used to reduce aqueous surface tension. The addition of oxyethylene substituents on the siloxane backbone increases hydrophilicity, while the polypropoxylated portion can be added to increase hydrophobic characteristics. The resulting nonionic surfactants reduce the surface tension of aqueous systems and allow good wetting of hair while enhancing foaming.

In addition to acting as emulsifiers or coemulsifiers, silicone polyethers can be used as resin modifiers to aid curl retention. They provide a mild lubricating effect, and some can be incorporated into shampoos and similar products to help reduce eye irritation from organic surfactants or to enhance foam. These materials are commonly used in shampoo formulations designed for daily use, where they provide light to medium conditioning with reduced fly-away. Because they are compatible in aqueous systems, silicone polyethers can be used in clear shampoos. Formulation is easy for both cold and hot processes, without the need for pre-emulsification, solubilizers or suspending agents.

Silicone elastomers offer the recognized properties of silicones, including reduced combing force; enhanced wet slip; soft, silky and dry feel; and reduced drying times. They can also be used to provide thermal protection, protection from color loss in semi-permanent and permanent colorants and improved hair volume.

Silicone Emulsions Make Formulating Easy

Easy, efficient formulating can be aided by silicones delivered in emulsion form, an approach that facilitates incorporation of potentially incompatible ingredients. It also allows simple pouring and mixing, as part of cold processes or with the addition of heat. Developments in emulsions and microemulsions capitalize on the properties of various families of silicones.

Amodimethicone and dimethyl emulsions offer the same benefits of fluids, with the added advantage of easy handling in aqueous systems. These emulsions provide the recognized soft and dry feel of silicone, as well as shine and a range of conditioning levels. When supplied as microemulsions, they can be incorporated into clear products.

Quaternary silicone emulsions can also offer new formulating options such as protection from heat, improved color retention, and enhanced body and volume. The quaternary ammonium functionality provides excellent wet and dry detangling, combing and feel properties. In microemulsion form, a product of this type can be used to create opaque and clear formulations for rinse-off and leave-on conditioners, shampoos and styling aids.

Summary and Conclusions

Consumer demand for hair care products goes beyond traditional washing and conditioning, and in response, chemical companies are creating new, high-performance silicone materials. These versatile and innovative ingredients are designed to treat hair damage caused by heat and color treatments, daily grooming and the environment — as well as to respond to today’s style trends. Recent studies also demonstrate that silicones can enhance hair strength, offering additional specialized solutions.

Silicone manufacturers continue to bring new technologies to the marketplace – with the common factor of development being predominantly market driven. For this reason, silicones will remain an essential ingredient for hair care products that offer consumers better results and provide manufacturers with increased sales and brand loyalty.

—Bethany K. Johnson, Dow Corning Corp.

On behalf of the Silicones Environmental, Health and Safety Council of North America