The beauty and wellness industry is one of the fastest growing industries in Asia, specifically in India. In 2005, the personal care product market in India was worth more than US $950 million, and it is growing at more than 15–20% per year.1 In recent years, the demand for organic, natural and nature-identical products has rejuvenated the importance of plant-based raw materials for personal care products rather than fossil fuel-based materials, which have received bad press.

Vegetable oils and their derivatives occupy a large share of these plant-based raw materials and a large quantity of them in their natural form are used in hair care. In India specifically, hair oils are popular products and one of the leaders on the market is coconut oil. In fact, the branded virgin coconut oil market alone in India accounts for better than US $260 million.2

The application of hair oil is an Indian tradition passed down through generations and spread nationwide. For 6,000 years, the country’s indigenous medicinal system of Ayurveda has instructed women to maintain their long tresses by heating various herbs in coconut or vegetable oils and massaging the mixture vigorously into the hair. This exercise, if conducted daily as a pre-wash conditioning step, has been said to lower the incidence of scalp conditions ranging from simple dryness, flakiness and itchiness to Tinea capitis and psoriasis.3 This exercise is also said to help keep the hair shaft soft and supple, thus reducing hair loss from combing or brushing.4 A typical hair oil used is shown in Formula 1.

Blended Oils

Less than 20 years ago, as more Indian women entered the workforce, they found the traditional use of hair oil to be time-consuming, cumbersome and messy, mainly due to the oily and sticky feeling of most vegetable oils. To address these concerns, blended vegetable oils were introduced to deliver the benefits of vegetable oil in a shorter time and without the mess.

As a result, the demand for blended vegetable oils benefited hair oil manufacturers since they could dilute vegetable oil with less expensive and synthetic substitutes like light liquid paraffin or white mineral oil. On average, light liquid paraffin or white mineral oil cost approximately US $1,504/ton whereas groundnut oil averages US $1,970/ton.

Initially the blends were nearly 80% vegetable oil and 20% light liquid paraffin but as more manufacturers began diluting oils, the blend was almost reversed.

While consumers generally were happy with the sensorial attributes of the diluted vegetable oil, they were not aware of the reduced efficacy caused by this dilution. A number of published reports document the ineffectiveness of light liquid paraffin as a skin or hair emollient or conditioner, mainly due to its inability to penetrate the scaly structure of the hair shaft or the skin barrier.4 Although vegetable oil alone can penetrate hair and skin, once it is blended with liquid paraffin, it becomes difficult to deliver skin or hair benefits, especially with high amounts of light liquid paraffin vs. small amounts of vegetable oil.5,6 Interestingly, one study found improved skin penetration with the use of coconut oil rather than liquid paraffin.7

As an alternative to light liquid paraffin, some manufacturers have used silicone oils as diluents. Silicones oils lower the surface tension of vegetable oils to enhance spreadability on the skin. This enhanced spreading was consumer-perceivable in a study comparing silicone/vegetable oil blends with pure vegetable oils.8 However, silicone oils are more expensive—costing approximately US $6,423/ton compared with US $1,970/ton for groundnut oil. In addition to cost, silicone oils have other limitations, including their synthetic and polymeric nature as well as low biodegradability.9 Yet, despite these challenges, they have been used successfully in personal care applications for nearly 50 years.

Vegetable Oil-based Esters

Besides light liquid paraffin and silicone oils as vegetable oil dilutents, vegetable oil-based esters provide an additional alternative and these will be the focus of the remainder of this article. Vegetable-based esters are capable of delivering the same benefits as light liquid paraffin and silicones, including the ability to lower the surface tension and viscosity of vegetable oils.

Vegetable oils, also referred to as natural lipids, are triglycerides derived from plant sources. The vegetable oils used in personal care have been mechanically expelled from the seeds of plants and can therefore be considered 100% natural. Triglycerides are esters composed of one glycerin molecule bonded to three fatty acids—long chain carboxylic acids in which the alkyl chain contains six or more carbons. This structure is depicted in Figure 1, where R1, R2 and R3 are fatty acids.

The three fatty acids in a triglyceride can have equal or different chain lengths, and their carbon chain can be saturated or unsaturated. For example, the fatty acid composition of triglycerides derived from coconut are rich in lauric acid—i.e., saturated C12 fatty acid, while those from palm are rich in palmitic acid, saturated C16 fatty acid.

Vegetable oil esters are obtained from vegetable oil triglycerides or their fatty acids by reacting them with short chain linear or branched chain aliphatic alcohols, with the chain length ranging from C2 to C4. Certain esters are already listed by the Personal Care Products Council as being cosmetically acceptable materials,10 and their role in personal care products ranges from improving emolliency and moisturization, to enhancing penetration and restoring the barrier function of the skin.

Overall, the presence of esters in cosmetic formulations improves the feel of a formulation on the skin and hair.11

Relating Viscosity with Oil Spreadability

As noted, consumers often perceive vegetable oils as tacky or sticky, and these attributes are associated with the surface tension and viscosity of a vegetable oil; in turn, these parameters impact the spreadability of an oil on the skin and hair. In order to establish the relationship between viscosity and oil spreadability, the authors examined three vegetable oils that are common in India—coconut oil, sunflower oil and groundnut oil—and blended them with vegetable oil-based esters in varying amounts to take several measurements.

Since palm oil and its derivatives are economical raw materials and easily obtainable in India, the esters used for the study were derived from the acid catalyzed esterification of palm fatty acid distillate (PFAD) with isopropyl, butyl and isobutyl alcohol. Each of these oils was blended in different ratios with isopropyl ester (IPE), n-butyl ester (NBE) and isobutyl ester (IBE), and their viscosities and spreadability were tested. The chemical structures of these compounds, respectively, are:

R1–CO–O–CH–(CH3)2

R1–CO–O–(CH2)3–CH3

R1–CO–O–CH2–CH–(CH3)2

where R1 represents the fatty acid component present in the PFAD.

Measuring Viscosity

Viscosity is the measure of a fluid’s resistance to flow. It describes the internal friction of a moving fluid. Therefore, a fluid with large viscosity resists motion since its molecular makeup gives it high levels of internal friction. In turn, a fluid with low viscosity flows easily because its molecular makeup exhibits little friction when it is in motion. Together with high surface tension, viscosity can contribute to tackiness of a liquid. Thus, lowering the viscosity would also improve the spreadability and feel of the vegetable oil on skin and hair.

Since spreadability is associated with fluids in motion, an Ostwald U-tube viscometer was used to determine the kinematic viscosity of the samples. This method is known in the petroleum industry as ASTM D445 or ISO 3104–Determination of Viscosity of Transparent Liquids–Ostwald’s U-Tube of special dimensions. The various dimensions are tabulated in the British Pharmacopoeia, Appendix V H (2003).

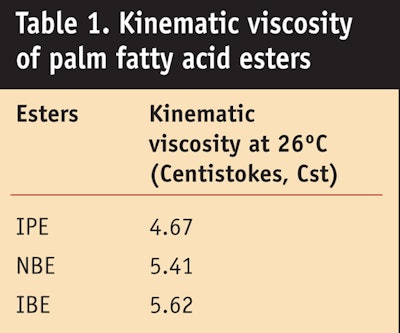

Most esters have an inherent low viscosity (see Table 1) since the carboxylic group, which is blocked by an alkyl group, does not participate in hydrogen bonding. Further, if this alkyl group is branched, as in the case of isopropyl and isobutyl, the non-linearity helps in improving the flow properties.

Measuring Spreadability

The spreading characteristic of cosmetic oils refers to how easily they are applied and distributed onto skin. In general, the more readily an oil spreads on skin, the more pleasant it feels to the consumer. Transparent polyacrylate sheets (210 mm x 297 mm) were used for this test, to which 1 mL of each sample was applied using a 1 mL pipette. The spreadability of the samples was checked using a micrometer scale at 5 min and 30 min. Spreadability was calculated by subtracting the droplet size measured at 300 sec from its size at 1,800 sec, then dividing by the droplet size at 300 sec, as shown here:8

Oil Size at − Size at

Spreadability = 1,800 sec 300 sec

Size at 300 sec

All values for this test were compared at 26˚C and 75% relative humidity. Each value reported was the average of three test results.

Results

The viscosity of the pure vegetable oils was lowered when blended with any of the three palm fatty acid esters, and the relationship between the blend ratio and reduction in viscosity was linear.

Figure 2 depicts the viscosity versus blend ratio of sunflower oil (SFO) and its blends with the three esters. Similarly, Figure 3 and Figure 4 illustrate the viscosities of groundnut oil (GNO) and coconut oil (CNO), respectively.

Whereas the viscosity of the oils decreased by incorporation of the esters, the oil spreadability increased as the amount of esters increased. The oil spreadability versus the blend ratio of SFO and its blends with the three esters is also represented in Figure 2; similarly, Figure 3 and Figure 4 show the spreadability of GNO and CNO, respectively.

Discussion

While blends ranging from 5% to 95% ester in oil were prepared, only those that provided optimum performance are reported here. Blends incorporating ≤ 10% ester were similar to the unblended oil in physical and performance parameters. On the other hand, blends having > 70% ester were similar to the pure ester (see Table 1) in physical and performance parameters. The synergy between the vegetable oils and esters appeared only when more than 10% ester was included and continued up to approximately 70% ester. Beyond this ratio, the synergy was lost. Hence, both ends of the scale were discounted in this study.

The inverse relationship between viscosity and spreadability also is shown in Figure 2, Figure 3 and Figure 4. As can be seen, when the spreadability data is arranged in ascending order, the viscosity data does not follow a linear descending order. This is due to the different viscosity and spreadability parameters of each of the three esters. For example, SFO blended with 30% IPE, had higher spreadability than SFO with 50% IBE, although the viscosity of the 50% IBE blend was much lower than the 30% IPE blend. This is an indication that with just three oils and three esters, a wide palette of permutations and combinations can be created to design products with a variety of tactile properties.

Market Viability of Vegetable Esters

In order to translate these findings into a commercially viable project, the authors compared this data to attributes of the most popular commercial hair oil blends on the Indian market, for which the same parameters of viscosity and spreadability were determined. These results are shown in Figure 5 and Figure 6.

This data indicates that the viscosity and spreadability values of the commercial hair oils are not aligned with those of the pure vegetable oils or their blends with esters. This could be attributed to the addition of silicones to the products since silicones have been reported to lower the surface tension and enhance the spreading of vegetable oils.8 Based on these findings, the viscosity and spreadability parameters of the three commercial hair oils were graphically compared with those of the pure vegetable oils and some selected blends.

Each commercial product was found to match one or more of the tested ester blends in either viscosity or spreadability but not both parameters at once. For example, the spreadability of Product D was similar to GNO 100%, whereas its viscosity matched the SFO blended with 20% IBE. In addition, the viscosity and spreadability of the commercial hair oils did not follow a linear relationship as demonstrated by the ester blends.

Conclusions

The present study illustrates that the addition of 10–30% vegetable oil-based esters to formulas lowers the viscosity of vegetable oils and improves their spreadability. While their application in hair oils were the main focus of this article, Formula 2, Formula 3 and Formula 4 provide examples of the esters in other types of products.

Vegetable oil-based esters are an eco-friendly option for formulators working with vegetable oil blends. The improvement in tactile attributes will satisfy consumers who not only find the use of pure vegetable oils messy, but also demand organic, natural and nature-identical raw materials. These esters can spawn an innovative range of skin and hair care products to deliver novel tactile and aesthetically pleasing attributes.

References

1. P Bhattacharya, India’s Cosmetic Market Ready for Big Leap, Global Cosmetic Industry 174(1) 42–44 (2006)

2. Marico Information Update (Jul 24, 2008)

3. B Fife, J Kabara and C Dayrit, The Health Benefits of Virgin Coconut Oil, Maggie Vandenbrekel e-Publishing (2002)

4. AS Rele and RB Mohile, Effect of mineral oil, sunflower oil and coconut oil on prevention of hair damage, J Cosmet Sci 54(2) 175–192 (2003)

5. K Keis, D Persaud, YK Kamath and AS Rele, Investigation of penetration abilities of various oils into human hair fibers, J Cosmet Sci 56(5) 283–295 (2005)

6. SB Ruetesch, YK Kamath, AS Rele and RB Mohile, Secondary ion mass spectrometric investigation of penetration of coconut and mineral oils into human hair fibers: Relevance to hair damage, J Cosmet Sci 52(3) 169–184 (2001)

7. K Sankaranarayanan, JA Mondkar, MM Chauhan, BM Mascarenhas, AR Mainkar and RY Salvi, Oil massage in neonates: An open randomized controlled study of coconut versus mineral oil, Indian Pediatrics 42(9) 877–884 (2005)

8. A Girboux and E Courbon, Enhancing the feel of vegetable oils with silicones, Cosm & Toil, 123(7) 49–56 (2008)

9. Applied & Environmental Microbiology, vol 65, no. 5 (May 1999) pp 2776–2778

10. Cosmetic Ingredient Dictionary 5th edn (1993) and CTFA Cosmetic Ingredient Handbook 2nd edn (1992)

11. Harry’s Cosmetology, 8th edn (2000) pp 355–356