Optimization of the sensory properties in emulsion systems is an ongoing challenge for formulators. Here, the authors present a tool designed to simplify the process. This visual tool called SensiMap assists formulators in selecting the right combination of specific crosslinked acrylic rheology modifiers and specialty emollient esters to match the desired formulation aesthetic profile. Rheology modifiers impact the texture element of sensory, particularly during the initial application (rub out) and emollient esters enhance sensory through to after feel.

Rheology Modifiers: Carbomer and Acrylates/C10-C30 Alkyl Acrylate Crosspolymer

Carbomers and acrylates/C10-C30 alkyl acrylate crosspolymer rheology modifiers are known for their ability to modify flow and texture while stabilizing emulsion systems. In addition to these properties, they have potential for enhancing other attributes such as sensory, which has never been fully explored by the industry.

Rheology modification and stabilization are accomplished through a space-filling mechanism. When dispersed in water, polyacrylic acid begins uncoiling. Neutralization of it with a base creates negative charges along the backbone and these repulsive forces uncoil the polymer into an extended structure. Thus, the crosslinked acrylic polymers occupy the entire aqueous phase of the formulation.

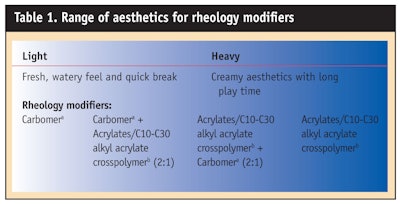

Certain self-wetting carbomersacan convey aesthetics of lightness and freshness, whereas a specific self-wetting acrylates/C10-C30 alkyl acrylate crosspolymerbimparts richness and creaminess. It is important to note that specific grades of rheology modifiers were used in the present formulating tool concept and that they are referenced here by their INCI names; however, INCI names alone do not indicate sensory performance.

Rheology Modifier Contribution to Sensory

Gel or emulsion formulations containing certain carbomersabreak quickly on a salt-containing substrate such as skin. This quick break delivers a high degree of wetness, a light and spreadable touch and a fresh feel. Formulations containing a specific acrylates/C10-C30 alkyl acrylate crosspolymerbretain greater structural integrity in the presence of electrolytes and therefore deliver richer, creamier aesthetics with extended playtime.

Figure 1 shows a range of electrolyte tolerance in gels using a specific carbomeraand acrylates/C10-C30 alkyl acrylate crosspolymerband blends of the two polymers used at a level intended to reach a target viscosity of 25,000–30,000 mPa·s (RV, 20rpm).

Figure 2 illustrates the correlation of electrolyte tolerance to sensory properties using test data generated by 13 trained external sensory panelists. Testing was performed by a modified procedure given by ASTM International,1 where 0.03mL is dispensed in the approximate center of a 40-mm diameter circle; RH = 50 ± 5%; temperature = 23 ± 1.5°C.

Attributes were evaluated using a forced ranking test. Friedman’s analysis of variance2 was used to determine statistical significance. A 95% confidence interval for difference is represented. Results clearly indicated sensory differences between the two polymers and the respective blends, and those differences were consistent with the electrolyte tolerance previously described.

The panel tests further suggest that the influence of these crosslinked acrylic rheology modifiers on sensory properties may extend into after feel aesthetics as well. After feel is the final stage of the sensory experience immediately after the formulation has dried. Clearly, crosslinked acrylic rheology modifiers delivered differentiated sensorial properties.

A visual depiction presented in the simplified terms of “light” and “heavy” is shown in Table 1, which demonstrates the range of aesthetics for the tested carbomer and acrylates/C10-C30 alkyl acrylate crosspolymer.

Emollient Esters

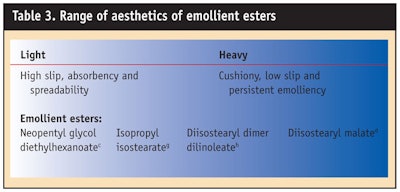

Within a range of complex emollient esters, richness, spreadability, slip and persistence of emolliency can be tailored to deliver the tactile performance required for formulations. Light esters such as neopentyl glycol diethylhexanoateccan provide a soft feel with high slip and fast absorbency, while heavy esters such as diisostearyl malatedcan convey richness and elegance.

Absorbency is the gradual dissipation of sensory intensity, while spreadability describes the application of a product across the skin.

Emollient Contribution to Sensory: Complex Esters

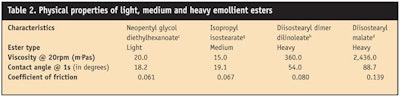

Emollients that are low in viscosity are included in the light category of emollients and generally have greater absorbency. Light esters have a low contact angle and therefore spread easily onto skin. The contact angle is the angle formed by a liquid on a solid surface at the air-solid-liquid interface, indicating the ability of a liquid to wet or spread on a solid. Measurements were taken with esters on synthetic skineusing an optical angle devicef.

Light esters also have a high degree of slip and lubricity, as evidenced by their low coefficients of friction. This attribute is measured using a Cameron-Plint reciprocating rig configured as described in the literature.3

Heavy esters have a higher coefficient of friction, indicative of a rich application experience with low slip. Esters such as isopropyl isostearategand diisostearyl dimer dilinoleatehare used when more moderate sensory properties are desired, or in blends with lighter and heavier emollients to provide a uniform transition between contrasting sensory properties.

Light-medium-heavy distinctions in emollients are demonstrated through physical property measurements in Table 2 and are further supported by sensory panel results in Figure 3.

For simplicity, these interrelated attributes can be reconciled into a single easy-to-read range, shown in Table 3. In the range of complex aesthetics for esters, neopentyl glycol diethylhexanoatec and diisostearyl malatedare depicted here as the opposite ends of the spectrum for light and heavy. The esters isopropyl isostearategand diisostearyl dimer dilinoleatehare shown to have properties in between.

The Sensory Contribution Continuum

The Sensory Contribution Continuum, as the authors refer to it, in Figure 4, provides a fresh perspective on formulation sensory aspects in consideration of all the stages of the sensory experience. This continuum is a graphical representation of the relative perceived sensory effect intensities throughout the stages of o/w emulsion treatments, as contributed by key formulation ingredients. Using this representation, formulators can optimize formulas for specific skin feel and can also target that skin feel for specific stages during application. In the present model, the authors are considering the impact of self-wetting crosslinked acrylic rheology modifiers and specialty emollient esters. Additional ingredient types may be the subject of future studies.

When an o/w emulsion is first applied to skin, the texture has a distinctively wet character. The period during which the wet character persists is referred to as the Rub out I stage. Wetness and spreadability provide a fresh feel when at high levels, or a creamy feel when at low levels, and are expressed during this stage of application. Wetness is defined here as the amount of water content that is perceived while rubbing. These parameters are typically observed in the first three to 15 application rubs.

Sensory properties of Rub out I are dominated by products that reside in the aqueous phase. As a result, crosslinked acrylic rheology modifiers dominate the skin feel during Rub out I, with the contribution of the emollient esters being less noticeable. By selecting a particular grade of crosslinked acrylic rheology modifier, one can then customize the sensory to deliver targeted aesthetics for the initial application stage.

As the emulsion breaks and the water begins to evaporate, wetness subsides but fluidity remains. This stage of application is called Rub out II. Most sensory evaluations do not characterize or measure this stage but it is clearly noticeable from sensory signals. In this stage, the sensory contribution from the nonaqueous phase begins to dominate and delivers the majority of the sensory signals such as slip, spreadability and cushion. Cushion is the sensory perception of material occupying the space between the finger and the skin; it is also referred to as thickness. Selection of the emollient ester, while taking into account the less noticeable but still perceivable rheology modifier impact, can allow the formulator to customize aesthetic features for this intermediate stage of sensory experience.

The after feel stage is signaled by the disappearance of emulsion fluidity and the appearance of dry feel. Within this stage, the sensory properties of the formulation are predominately driven by the emollient choice. The rheology modifier exists in a concentrated form in this stage and will have an impact on sensory perception, although minimal relative to the emollient contribution. The slip imparted by the emollients remains from Rub out II. Emollient esters with lower (longer) absorbency are perceived as providing more persistent emolliency.

The formulator can now select a specific sensory profile for emulsion formulations by combining the sensory properties of seemingly unrelated technologies: crosslinked acrylic rheology modifiers to impact the texture element and initial application stage of sensory; and complex emollient esters to enhance sensory during application through to after feel.

Feeling is Believing

By considering the previously presented ranges of aesthetics for both crosslinked acrylic rheology modifiers and emollients esters, a formulator could visualize a 2 x 2 matrix or Sensory Combination Matrix, as shown in Figure 5.

A light carbomeracombined with a light emollient ester such as neopentyl glycol diethylhexanoatec can provide a refreshing sensory experience. These attributes impart a fresh feeling, ideal for daytime preparations or facial moisturizers such as toners, lotions and milks. This light carbomer, light emollient ester combination (LL) yields a high degree of wetness and spreadability in Rub out I, quickly followed by continued spreadability with high slip in Rub out II. Slip then persists into after feel but overall emolliency is not sustained for extended periods. This combination of sensory helps to reinforce a refreshing experience during the use of a product.

When indulgence is the desired sensory message, the heavy carbomer, heavy emollient ester combination (HH) is recommended. HH formulations exhibit rich, creamy aesthetics through an extended Rub out I stage, further characterized by low wetness and spreadability such as from acrylates/C10-C30 alkyl acrylate crosspolymerb. Richness continues into Rub out II application stage as the impact of the heavy emollient ester dominates and provides cushion and reduced slip and spreading. These aesthetics are ideal for richer products such as night creams and moisturizing masks.

The heavy carbomer, light emollient ester combination (HL) in the luxurious quadrant offers long play time with a light, silky after feel. These attributes make for good formulations where extended application time is desirable without a heavy persistent after feel, such as spa products or pedicure creams.

Finally, the light carbomer, heavy emollient ester combination (LH) is surprising and perhaps best illustrates the potential of using the Sensory Contribution Continuum to create unexpected and unique sensorial experiences in formulations. The LH combination has a light, fresh initial impression that quickly transforms into a richer substantive feel. This light-heavy combination offers intriguing possibilities for products such as eye creams.

Formulating with the SensiMapj Model

Changing rheology modifiers and emollients esters will shift the shape of the Sensory Contribution Continuum. For various combinations, the shapes of the continua may be shown as indicated in Figure 6, a combined formulating guide.

These shapes were determined through a series of roundtable sensory analysis performed by Lubrizol/Noveon on a global basis, characterized by intensive and iterative evaluations of various compositions in four simple screening emulsions. The figure contains four Sensory Contribution Continua representing the four quadrants from the previously described SensiMap model, the ingredient ranges of aesthetics and simplified sensory data. The result is a simplified sensory tool to help direct ingredient selection to meet aesthetic needs.

For the LL and LH quadrants in Figure 6, carbomeracurves have steeper downward slopes than acrylates/C10-C30 alkyl acrylate crosspolymerb, which is used for HL and HH curves, especially when comparing Rub out I and Rub out II application stages. These two stages are shorter in time for carbomera than for acrylates/C10-C30 alkyl acrylate crosspolymerb. This result is due to acrylates/C10-C30 alkyl acrylate crosspolymerbbeing less sensitive to electrolytic surfaces such as the skin and maintaining its structural integrity during a prolonged Rub out I. The extended rub out stages explain why the HL and HH curves are somewhat longer overall than the LL and LH curves.

The emollient ester curves for the LL and HL quadrants are shown to gradually decrease toward the end of the after feel stage. This reflects the longer persistency properties of the heavy emollient diisostearyl malated, compared with the light, faster-absorbing ester neopentyl glycol diethylhexanoatec.

Identifying and Characterizing Sensory Differences

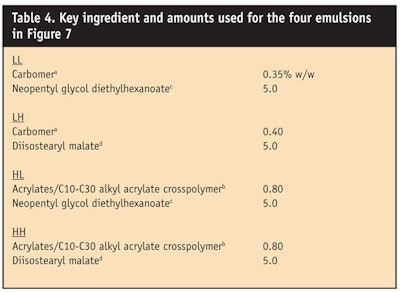

Emulsion samples may be used to demonstrate differences between the various Sensory Contribution Continua. For this purpose, sensory data (Figure 7) was generated using emulsions made with 5% w/w ester and the amount of rheology modifier required to obtain an emulsion viscosity of 25,000–30,000 mPa·s (Brookfield RV, 20 rpm @ 23°C). The key formulation ingredients for the four emulsions are shown in Table 4.

The data provided in Figure 7 further validates the differences indicated in the shape of the curves shown in the combined formulating guide. Wetness and spreadability values for the LL and LH quadrants are much higher than those determined for the HL and HH. Low levels of wetness and spreadability correlate with the cushiony feel imparted by the acrylates/C10-C30 alkyl acrylate crosspolymerb. The rub out characteristic for each emulsion appears to be largely determined by the choice of crosslinked acrylic rheology modifier. This further confirms why the initial sensory contribution curves for initial rub out stage shows the rheology modifier and ester contribution far apart, since the emollients play only a minor role in the initial application sensory. In contrast, the after feel sensory contribution is dominated by the emollient ester, with only a small, less significant contribution from the rheology modifier.

In Figure 7, HH is shown as having greater persistence of emolliency than LH and HL, with LL the least. This further reinforces the finding that acrylates/C10-C30 alkyl acrylate crosspolymerbhas a greater contribution to sensory after feel than carbomera, as was reflected in Figure 6 where the rheology modifier after feel curves were determined to be higher for HH and HL than LH and LL. This difference is further accentuated since it is typically used at higher use levels in simple emulsions.

Conclusion

The SensiMap formulating concept provides simplified tools to help formulators approach sensory with a different perspective. By selecting the right combination of rheology modifiers and emollient esters, a customized aesthetic experience can be obtained delivering sensory at the proper stage of application, eliciting the targeted emotional response from consumers during product use.

References

1. ASTM E 1490-03, Standard practice for descriptive skinfeel analysis of creams and lotions, ASTM International Web site, available at: www.astm.org/snews/may_2003/acte_may03.html (Accessed May 20, 2008)

2. M Meilgaard, G Ceville and B Carr, Sensory Evaluation Techniques 3rd edition, CRC Press LLC, USA (1999)

3. M Truong, K Hughes, V Lvovich, J Woo, B Moran and A Suares, Novel Methods for Emollient Characterization, presented at the IFSCC conference, Florence, Italy (2005)