The term medical device often elicits mental images of solid, fabricated objects such as coronary stents, replacement joints, surgical sutures or adhesive bandages. Nonetheless, the term can also refer to fluid, formulated products. Personal lubricants (PLs) are a prime example of such formulated medical devices. Not only are PLs an important accessory to the practice of medicine, they also are the cornerstone of the rapidly growing intimate health or intimacy enhancement category in the over-the-counter (OTC) consumer health care marketplace. The purpose of this article is to provide a general review of PLs and to demonstrate how polymer science is essential to enabling innovation in this unique class of medical devices.

Personal Lubricants

Lubrication is defined as the separation of moving surfaces to prevent them from coming into contact with each other; the benefits of lubrication are the reduction of friction between the surfaces and the prevention of mechanical wearing of the surfaces.1 Thus, a lubricant is any material that performs the function of lubrication. PLs are fluid lubricants intended to reduce the friction associated with contact between human tissue and another moving surface; e.g., the surface of a medical device or other human tissue. PLs are also referred to as surgical lubricants or patient lubricants.

PLs are typically used in medical settings to enhance patient comfort during internal examinations, for example digital prostate exams in men or pelvic exams in women. PLs also facilitate the insertion of diagnostic and therapeutic devices into body orifices; examples of such devices include vaginal specula and urinary catheters.

Outside of the clinic, PLs are sold as OTC products and used by consumers to relieve symptoms of vaginal dryness and to lubricate medical devices such as condoms, tampons and rectal thermometers. However, PLs are becoming increasingly popular in the consumer marketplace because of their ability to enhance the comfort and pleasure of intimate activities.

Regulatory Classification

In most countries around the world, government regulatory agencies classify PLs as medical devices. For example, in the United States, the US Food and Drug Administration (FDA) applies a three-level, risk-based classification system to medical devices.2 In this system, PLs are classified as either Class I or Class II Medical Devices according to their intended use and indications for use. PLs usually fall into the lowest risk category, Class I.3 These devices must be manufactured with documented general quality controls but they typically do not require a 510(k) submission to the FDA.4, 5 However, if a PL is indicated for use with a condom—i.e., a condom-compatible claim is made, then the PL is elevated to Class II device classification since it is then considered an accessory to a Class II device (the condom).6

The Class II PLs are regulated more stringently. In addition to general quality controls, the devices must meet performance standards or special controls to demonstrate safety and efficacy.2 In the case of Class II PLs, condom compatibility must be demonstrated using a test such as ASTM D-3492, Standard Specification for Rubber Contraceptives (Male Condoms). For Class II PLs, a 510(k) approval is required before the device can be marketed in the United States.

A Brief History

Since ancient times, a variety of materials have been employed as lubricants, including animal fats, vegetable oils and other plant extracts; e.g., resins. The ancient Romans were known to have used animal fats as lubricants1 and there are numerous biblical references to anointing the body with oils, which are indeed lubricants. Though it is not explicitly documented, it is not unreasonable to envision that such materials were used in the same manner as modern PLs are used today. In the modern era, castor oil was reported in 19th century medical literature as a surgical lubricant.7

The birth of the oil refining industry in the mid-1800s gave way to a new generation of hydrocarbon lubricants derived from petroleum.1, 8 These new lubricants would eventually find use as PLs, with petrolatum and mineral oil being the two petroleum-based products most commonly employed as PLs. Although they provide the benefit of lubrication, the hydrocarbon lubricants exhibit several deficiencies when used as PLs, including poor aesthetics, i.e., an unnatural, greasy feel; difficult clean-up due to lack of water-solubility; and most importantly, incompatibility with latex rubber condoms—hydrocarbons compromise the integrity of the condom by plasticizing and weakening the rubber.

The first modern, water-soluble lubricants were introduced in the early 20th century. These formulas were generally sterile aqueous solutions of naturally occurring polysaccharides and glycerin.9–1 1The benefits of these lubricants included a tremendous improvement in lubrication comfort because of their more natural aesthetics and more lubricious formulas, nonstaining and easier-to-clean-up formulas due to water-solubility, and compatibility with latex rubber condoms.

Widely recognized in personal lubricants, the K-Ya brand dates back to 1904, when suture maker Van Horn and Sawtell first began marketing its “Antiseptic Nonfatty and Soluble Lubricating Jelly” under the trademark, which was officially registered in 1906.12

The brand was then acquired by Johnson & Johnson in 1918 when the company purchased the Van Horn and Sawtell business.

During the next half-century, little innovation occurred in PLs and only a few competing generic products such as the Surgilube brandb emerged in the marketplace.

The year 1980 marked a significant milestone in PL history when PLs were first sold as an OTC item, allowing consumers easier access and initiating the mainstreaming of PLs in the OTC health care market.

In the early 1990s, PLs experienced a boom period with the emergence of many new brands such as Wetc, Astro-glided, IDeand Replensf, yet the products remained primarily niche items.

The 1996 launch of a PL liquidaintroduced an aesthetically favorable product to the mass market. Unlike the jelly used in medical settings, this liquid proved more appropriate for intimacy enhancement and gained popularity with consumers for this purpose. The combination of product introductions and changing consumer needs led to the rise of the intimacy enhancement category in the early 21st century. Perhaps the most significant innovation during this recent period was introduction ofself-warminga PLs in 2003.

Water-based PL Formulations

Most PLs are water-based formulations that rely on water-soluble polymers to deliver lubricity, viscosity and distinct rheological characteristics. The chemical and physical properties of the polymers used in water-based PLs play a significant role in determining PL formulation aesthetics and performance.

A water-based PL is a complex matrix of ingredients that must be formulated to meet both stringent performance requirements and consumer expectations. Since PLs are intended for internal use, the formulations must be noncytotoxic, nonirritating and highly biocompatible. Additionally, PLs intended for use as Class II Medical Devices must demonstrate condom compatibility. The products must provide comfortable, long-lasting lubrication that feels natural to the consumer—i.e., the lubricity should mimic that of the body’s natural lubricating fluids. Formulations should be nonstaining to fabrics and also meet ease-of-use requirements, including easy application and simple clean-up.

Basic Elements of Modern Water-based PL Formulations

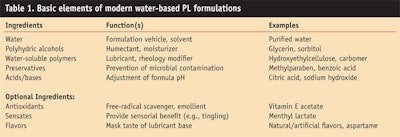

The primary ingredient in a water-based PL formulation is of course water, usually comprising 50–90% w/w of a formula (see Table 1).13–17

Polyhydric alcohols such as glycerin or sorbitol are the second most prominent ingredient in PLs; these components function as humectants to enhance product lubricity and moisturization. Although water-soluble polymers may comprise less than 1% w/w (typical use range = 0.1–3%), they are perhaps the most critical ingredient in a PL formulation. The polymers are responsible for providing lubricity, i.e. slipperiness; modifying product rheology; and ultimately play a critical role in determining overall formulation aesthetics. Depending on polymer selection and use level, product consistencies can be varied from thick jellies to thinner pourable liquids and even low viscosity sprayable fluids.18

As aqueous solutions of polymers are susceptible to microbial growth, preservatives such as methylparaben and benzoic acid are critical ingredients in water-based PLs to ensure product safety. PL formulations are adjusted to physiologically compatible pH values with the aid of common pH adjusters such as citric acid and sodium hydroxide. An example of a water-based personal lubricant composition is shown in Formula 1.15

The ingredients shown represent the critical components of a basic PL formulation. However, to increase consumer appeal and to increase the “wow” factor, formulators can include a variety of optional ingredients to provide additional benefits (see Table 1). For example, PLs may include antioxidants to scavenge free radicals and to provide longer-lasting moisturization.19, 20 Addition of ingredients such as vitamin E acetate is especially common in products designed for vaginal moisturization. Sensates can be added to PLs to provide enhanced stimulation and arousing sensorial benefits, such as tingling or flushing. To mask the flavor of a PL base, a variety of flavors and sweeteners can also be added to the PL formulation.

Water-soluble Polymers

A variety of water-soluble polymers may be employed in aqueous PL formulations (Figure 1).21

These hydrophilic polymers can be categorized into three representative groups based on their electrostatic properties: nonionic (uncharged), anionic (negatively charged) and cationic (positively charged). Nonionic polymers tend to be used most often in water-based PLs (see Figure 1a). Examples of such polymers include hydroxyethylcellulose, polyethylene oxide and polyglyceryl methacrylate. These polymers contain many oxygen atoms, present primarily in hydroxyl (–OH) or ether (–O–) functional groups. Such functional groups readily participate in hydrogen bonding interactions with water and polyhydric alcohols, making the polymers very compatible with the PL solvent matrix.

Ionic polymers or polyelectrolytes are also employed in PLs. Sodium carboxymethylcellulose and carbomer (crosslinked polyacrylic acid) are common examples of anionic polymers found in PLs (see Figure 1b). In addition to lubricity and rheology modification, polycarboxylic acids such as carbomer can also offer a pH-buffering benefit in vaginal moisturizer formulations.22–24 Since the ideal vaginal pH is slightly acidic (ca. pH = 5), these weak acids can function in the vagina as a bioadhesive buffer system to maintain the acidic pH over time. Buffering the vagina to acidic pH promotes the growth of beneficial microflora, e.g., lactobacilli, and prevents proliferation of the alkaline-loving anaerobic bacteria that can lead to bacterial vaginosis. Though less common than their anionic counterparts, cationic polymers are also found in PL formulations (see Figure 1c).Polyquaternium-15 is perhaps the most popular cationic polymer used in PLs, while guar hydroxypropyltrimonium chloride is used to a lesser extent.

While there are many distinct polymer chemistries that can be used to formulate water-soluble PLs, all of these polymers have many chemical and physical properties in common. As shown in Figure 1, the polymers found in water-based PLs contain many polar functional groups and functional groups that are capable of hydrogen bonding; thus, the polymers are extremely hydrophilic and readily bind large amounts of water. The polymers tend to be of very high molecular weight (MW), generally exceeding 1 ´ 106 g/mol. The chemistry of the polymers also renders them extremely biocompatible and thus ideal for application in PLs.

Macroscopically, the polymers readily dissolve in polar solvents; e.g., water or mixtures of water and polyhydric alcohols, to form clear solutions. On the molecular level, the polymers exhibit expanded chain conformations due to highly favorable polymer-solvent interactions. Depending on the polymer chemistry and solvent quality, polymers found in PLs usually exhibit expanded random coil to rigid rod conformations, with Mark-Houwink-Sakurada a values typically exceeding 0.7.25 Because of their high MW and expanded chain conformations, these polymers possess extremely large hydrodynamic volumes and can entangle to form semi-dilute solutions at relatively low polymer concentrations; i.e., the polymers exhibit low values of critical overlap concentration, C*.26

Thus, it is possible to achieve high solution viscosities in PL formulations with relatively low polymer concentrations, and rheology modification is achieved in an efficient manner. Collectively these chemical and physical solution properties play an important role in the mechanisms of lubrication exhibited by water-based PLs.

Lubrication Mechanism

The principle mechanisms of lubrication include hydrodynamic lubrication, elastohydrodynamic lubrication and boundary lubrication.1,27,28 Water-based PLs exhibit a hybrid lubrication mechanism that is a composite of these classical mechanisms, referred to as mixed film lubrication. The primary mechanism exhibited by PLs is hydrodynamic lubrication (see Figure 2a).

In this mechanism, friction between the two surfaces is prevented by a fluid film of the PL. The two surfaces glide past each other with the fluid film separating surface asperities and preventing them from coming into contact. On the microscopic level, the fluid film is composed of an entangled network of polymer coils that are swollen with the mixed aqueous-polyhydric alcohol solvent. The polymer network acts as a cushion and viscosifies the solvent to maintain the integrity of the fluid film in contact with the surfaces. Additionally, the polyhydric alcohols in the PL formulation lower the surface tension of the fluid, enabling efficient wetting of both surfaces by the fluid film.

Elastohydrodynamic lubrication is a variation of hydrodynamic lubrication where one surface undergoes an elastic deformation (see Figure 2b). In this case, the surfaces remain separated by the PL, but the fluid film transfers the force exerted by the device surface into the tissue surface, which then deforms and recovers when the force ceases to be exerted.

Boundary lubrication represents the case when the fluid film becomes so thin that the surface asperities of the device and the tissues begin to contact each other (see Figure 2c). However, lubrication is still achieved because a layer of PL only molecules thick separates the surfaces to prevent actual contact and wear. Boundary lubrication is less likely to be observed in actual PL use. As the solvent is squeezed out from between the surface asperities, the polar functional groups of the polymer would be attracted to both surfaces and the polymer would begin to exhibit adhesive properties. Macroscopically, this would be perceived as tacky, draggy aesthetics and the user would either rewet the PL or apply more PL, once again enabling hydrodynamic lubrication.

Measuring Lubrication

Quantitative measurements of lubrication may be used to evaluate PL performance. Lubrication measurements typically involve determining the dimensionless coefficient of kinetic friction, mk, which is equal to the ratio of the frictional force, F, between two moving bodies and the normal force, N, pressing them together:1

(Eq 1)

PLs that exhibit lower values of mk are considered to be more effective lubricants. The effectiveness of lubrication may also be reported as lubricity, which is simply the inverse of mk.

Simple measurements of mk as a function of time can be achieved by measuring the force required to drag a metal disc of known mass across a glass plate that has been coated with a PL.15 More sophisticated instruments called texture analyzers enable measurement of friction reduction under conditions that are more representative of actual PL use.20 Special friction rigs that attach to the load cell of a texture analyzer have been designed to measure mk. One such rig, consisting of friction sledge that can slide back and forth over a lubricated platform, can be used to conduct measurements of mk in an oscillatory (push-pull) mode over a period of several minutes to simulate PL use under dynamic shear conditions.

Modern Anhydrous PL Formulations

The latest generation of PLs are anhydrous formulations that utilize polymers to provide long-lasting lubrication and unique sensorial experiences. Unlike their petroleum-derived predecessors, the chemistry of these anhydrous formulations renders them safe for use with latex condoms, allowing them to be indicated as Class II medical devices. The unique functional and aesthetic benefits of the modern anhydrous PLs continue to drive their increasing popularity with consumers and growth in the marketplace.

Warming Formulations

The process of mixing anhydrous polyhydric alcohols such as glycols or glycerin into water is exothermic and can release considerable amounts of heat. For example, the values of enthalpy of hydration, DHhyd, for glycerin and propylene glycol are 2.8 kJ/mol and 4.1 kJ/mol, respectively.29 The heat liberated is due to the rearrangement of the hydrogen-bonded water structure to accommodate the polyhydric alcohol molecules via hydrogen-bonding and hydrophobic hydration interactions.30 Self-warming PL formulations take advantage of polyhydric alcohols’ exothermic DHhyd to deliver a warming sensation to the user upon application.31,32 When these anhydrous formulas contact mucosal tissues, ambient water mixes with the formulation, liberating heat that is perceived by the user. This self-warming feature makes such PLs more comfortable to apply and adds a distinguishing “wow” factor to a PL product.

Polymers used in warming PL formulas must be highly soluble in the polyhydric alcohol to ensure adequate lubrication and rheology modification. Because polyhydric alcohols are less polar solvents than water, the polymers employed in warming PLs tend to be more hydrophobic in nature compared to those used in water-based PLs. For example, hydroxypropylcellulose is often used in place of hydroxyethylcellulose (see Figure 3).

Low molecular weight poly(ethylene glycol)s, e.g. PEG 400, are also used in warming PLs due to their miscibility in the polyhydric alcohols and their exothermic values of DHhyd.33,34 Although normally employed in water-based PL formulations, polyquaternium-15 is also found in warming PL formulations; it is likely soluble in the polyhydric alcohol solvent due to the addition of a low level of water as a cosolvent. An example of a anhydrous warming personal lubricant composition is shown in Formula 2.32

Silicone-based PLs

Silicone polymers are well-known as lubricants for a variety of applications.35 Silicone fluids exhibit very low surface tensions and have a strong propensity to spread on surfaces, enabling them to be good hydrodynamic lubricants. In the personal care industry, silicones are routinely employed in skin care products because of their ability to modify surface properties and deliver unique tactile benefits.36,37 Perhaps the most common silicone fluid in the industry, dimethicone (trimethylsiloxane-terminated polydimethylsiloxane, see Figure 4) is frequently used as a skin conditioning agent and a skin protectant because of its emolliency and skin feel.

The lubricity and biocompatibility of silicones has made them attractive polymers for use in PL applications,38–40 and several silicone-based PLs products are currently marketed.21 Most silicone PLs are comprised of dimethicone and dimethiconol (hydroxy-terminated polydimethylsiloxane, (see Figure 4) blended to achieve a desirable viscosity and tactile sensory profile; cyclomethicones (Figure 4) may also be incorporated into the product to modify product viscosity and in-use aesthetics.

Silicone-based PLs are notably different from their water-soluble counterparts. The anhydrous silicone fluids offer exceptional lubricity with a long playtime because they do not “dry out” and become tacky. The hydrophobicity of silicone PLs enables them to be effective lubricants in wet environments such as in showers or bathtubs, since they are not easily diluted and washed away; however, the insolubility of silicones in water also makes clean-up of silicone-based PLs more challenging. Since silicones do not interact with latex rubber, the silicone-based PLs are also attractive as condom-compatible lubricants. Nonetheless, the silicone-based PLs tend to be more expensive, premium-priced products compared to conventional PLs due to the higher cost of silicone raw materials, especially for those silicone fluids that are considered medical grade and must meet the requirements set forth in the National Formulary.

Summary

Modern PLs are a unique variety of medical devices that are essential accessories to many medical devices and procedures. Outside of clinical settings, OTC consumer use of PLs continues to grow as more people seek intimate health benefits and as more innovative products appear in the marketplace. As formulated medical devices, PLs rely on polymeric ingredients to deliver long-lasting, aesthetically desirable lubrication, and innovations in the intimate health category are frequently enabled via the creative application of polymer science and technology.

References

1.ER Booser, Lubrication and lubricants, in Kirk-Othmer Encyclopedia of Chemical Technology, Fourth Ed, JI Kroschwitz and M Howe-Grant, eds, vol 15, New York: Wiley-Interscience (1995) pp 463–517

2.Code of Federal Regulations, 21 CFR 860 Medical device classification procedures (2007)

3.Code of Federal Regulations, 21 CFR 880.6375, General hospital and medical use devices, Patient lubricant (2007)

4.Device Advice—General Controls for Medical Devices, United States Food & Drug Administration—Center for Devices & Radiological Health, Available at: www.fda.gov/cdrh/devadvice/363.html (accessed Feb 11, 2008)

5.Device Advice—Premarket Notification 510(k), United States Food & Drug Administration—Center for Devices & Radiological Health, Available at: www.fda.gov/cdrh/devadvice/314.html (accessed Feb 11, 2008)

6.Code of Federal Regulations, 21 CFR 884.5300, Obstetrical and gynecological therapeutic devices, Condom (2007)

7.AE Gallant, VI, Report upon the use of a mixture of castor oil and Balsam of Peru as a surgical dressing, Ann Surg 26(3) 329–339 (1897)

8.DS Morrison, Petrolatum: A useful classic, Cosm & Toil 111(1) 59–65, 69 (1996)

9.MJ Huston, BE Riedel, JR Murray, GA Groves and B Boyle, Formulation of a jelly base and a lubricating jelly, Can Pharm J 82(18) 32, 34, 45 (1949)

10.AL Taylor, Antiseptic lubricant for surgical gloves, Chemist and Druggist 116 192 (1932)

11.G Pegurier, The glycerate of gum tragacanth, Rep Pharm 246 (1912)

12. US Trademark 54,124, An antiseptic non-fatty and soluble lubricating jelly, assigned to Van Horn & Sawtell (Jun 19, 1906)

13. I Adams and SS Davis, Formulation and sterilization of a surgical lubricant gel based on carboxypolymethylene, J Pharm Pharmacol 25(8) 640–646 (1973)

14. I Adams, SS Davis and R Kershaw, Formulation of a sterile surgical lubricant, J Pharm Pharmacol 24(suppl.) 178P (1972)

15. US 5,885,591, Personal lubricant compositions, N Ahmad, GE Koll, SY Lin, R Toddywala and L Wearley, assigned to Johnson & Johnson Consumer Products Inc. (Mar 23,1999)

16. WO 9209256, Water-based human tissue lubricant, MH Gold, assigned to Medical Polymers Inc. (Jun 11, 1992)

17. US 2005158337, Rehydrating personal lubricant, JD Fleming (Jul 21, 2005)

18. US 2007059250, Sprayable personal lubricant comprising polyhydric alcohol, N Ahmad, C-J Cui, M Eknoian, R Walters, J Librizzi, M Morscherosch, B Ison and SJ Mohary, assigned to McNeil-PPC Inc. (Mar 15, 2007)

19. US 20070243219, Antioxidant compositions for reducing odor in warming lubricant compositions, N Ahmad, C-J Cui, VS Kamat and S Ng (Oct 18, 2007)

20. US 6,139,848, Personal lubricant compositions, N Ahmad, K Patel and M Huseth, assigned to McNeil-PPC Inc. (Oct 31, 2000)

21. MJ Fevola and T Lai, Survey of personal lubricant ingredients, label analysis, Jul 2007 (unpublished data)

22. US 6017521, Use of polycarboxylic acid polymers to treat vaginal infections, JR Robinson and WJ Bologna, assigned to Columbia Laboratories Inc. (Jan 25, 2000)

23. US 20060105008, Acid-containing compositions and methods for reducing vaginal pH, N Ahmad, C-J Cui, A Fu and SY Lin (May 18, 2006)

24. US 20070059278, Anhydrous composition containing an acid-acid buffer system for vaginal odor control, N Ahmad and C-J Cui (Mar 15, 2007)

25. M Kurata and Y Tsunashima, Viscosity-Molecular Weight Relationships and Unperturbed Dimensions of Linear Chain Molecules, in Polymer Handbook, Fourth Ed, J Brandrup, EH Immergut and EA Grulke, eds, New York: Wiley-Interscience (1999) pp VII/1-VII/83

26. FM Winnik, Elements of polymer science, Chapter 1 in Principles of Polymer Science and Technology in Cosmetics and Personal Care, ED Goddard and JV Gruber, eds, New York: Marcel Dekker, Inc. (1999) pp 1–50

27. AE Meyer, RE Baier, H Chen and M Chowhan, Differential tissue-on-tissue lubrication by ophthalmic formulations, J Biomed Mater Res B Appl Biomater 82B(1) 74–88 (2007)

28. J de Vicente, JR Stokes and HA Spikes, Soft lubrication of model hydrocolloids, Food Hydrocolloids 20(4) 483–491 (2006)

29. L Goudard and P Leydet, Heat of dilution of 1,2-propanediol and glycerol, Compt Rend 261(20(Groupe 7)) 4063–4068 (1965)

30. MY Nagamachi and AZ Francesconi, Measurement and correlation of excess molar enthalpy HmE for (1,2-propanediol, or 1,3-propanediol, or 1,4-butanediol + water) at the temperatures (298.15, 323.15, and 343.15) K, J Chem Thermodyn 38(4) 461–466 (2006)

31. US 7,005,408, Warming and nonirritating lubricant compositions and method of comparing irritation, N Ahmad, Y Sun and SY Lin, assigned to McNeil-PPC Inc. (Feb 28, 2006)

32. US 7,285,517, Warming and nonirritating lubricant compositions and method of comparing irritation, N Ahmad, CS Lamb and EC Lonardo, assigned to McNeil-PPC Inc. (Oct 23, 2007)

33. H Schoenert and F Monshausen, Calorimetric measurements on dilute solutions of polyethylene oxide in water, Colloid Polym Sci 258(5) 578–581 (1980)

34. GD Smith and D Bedrov, Roles of Enthalpy, Entropy, and Hydrogen Bonding in the Lower Critical Solution Temperature Behavior of Poly(ethylene oxide)/Water Solutions, J Phys Chem B 107(14) 3095–3097 (2003)

35. B Hardman and A Torkelson, Silicones, In Encyclopedia of Polymer Science and Engineering, HF Mark, NM Bikales, CG Overberger, G Menges and JI Kroschwitz, eds, vol 15, New York: Wiley-Interscience (1989) pp 204–308

36. AJ O’Lenick, Silicones for Personal Care, Carol Stream, IL: Allured Publishing Corp. (2003)

37. MD Berthiaume, Silicones in cosmetics, Chapter 7 in Principles of Polymer Science and Technology in Cosmetics and Personal Care, ED Goddard and JV Gruber, eds, New York: Marcel Dekker, Inc. (1999) pp 275–324

38. US 20070281008, Personal lubricant compositions and kits for providing personal lubrication, SY Lin, L Gentner and M Joyce Dec 6, 2007)

39. GB 2416992, Personal lubricant for contraceptive devices containing tocopherols and silicone fluid, M Hussein, assigned to Britannia Medicare Limited (Feb 15, 2006)

40. US 20050089537, Personal lubricant with silicone polymers, JC Birnholz (Apr 25, 2005)