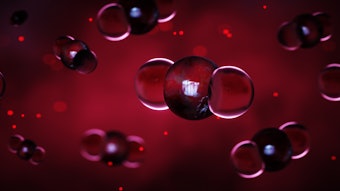

Nanoemulsions are transparent or translucent systems mostly covering the range 50-200 nm. Although they are only kinetically stable, they have long-term physical stability against flocculation or coalescence. This inherent stability is due to steric stabilization produced by the use of adsorbed nonionic surfactants and/or polymers.

The use of nanoemulsions in personal care applications offers several advantages: efficient delivery of active ingredients through the skin; transparency and low viscosity that may give a pleasant skin feel; and uniform deposition on the rough skin. However, one of the main instability problems with nanoemulsions is Ostwald ripening.

In this article, we will report results on the preparation and stabilization of nano emulsions using a novel polymeric surfactant, namely hydrophobically modified inulina (HMI). This polymeric surfactant had previously proved to be an excellent stabilizer for emulsions. It also has limited solubility in water and one would therefore expect it to strongly adsorb at the O/W interface. This will lead to an increase in the Gibbs dilational elasticity, thus reducing the Ostwald ripening rate.

Several oils were used for the preparation of nanoemulsions using a high pressure homogenizer. Both the oil volume fraction and the emulsifier level were also varied.