Traditional preservation methods have provided efficacy and affordability in countless cosmetic formulations. Traditional preservation methods typically involve the addition of biocidal or fungicidal compounds to a formulation to eliminate any microbes that exist after compounding the cosmetic product, and to protect the product from microbe proliferation after consumers insult once the package is opened.

Recent findings have suggested that many of the commonly used traditional preservatives such as parabens, isothiazolinones and formaldehyde donors may cause acute and/or chronic adverse effects when the products that include them are applied topically. In a digital age, this information is freely available to consumers and quickly disseminated. This has caused increased awareness and negative attitudes toward traditionally preserved products. Consumers now seek products that contain lower levels of traditional preservatives, and optimally, no traditional preservatives at all.

Hurdle Technology

The concept of “hurdle technology” for the preservation of products has been used in the food industry for many years. Hurdle technology is a holistic formulation approach that assesses the impact of multiple factors on the ability of a formulation to support microbial growth.

The name hurdle technology comes from the analogy to a hurdler, having to avoid multiple barriers over the course of a race, each time becoming more tired. This typically involves the selection and inclusion of one or more ingredients that have multiple functions during formulation development, and importantly, the use of good manufacturing principles to avoid any bio-burden prior to packaging. Some methods that are consistent with this approach are the inclusion of certain diols (alone, or in combination,) organic acids and chelating agents. Basic factors such as formulation pH and water activity can also play an important role in the hurdle method.

Caprylhydroxamic Acid

INOLEX has developed and patented innovative systems that utilize hurdle technology to allow formulators to create products that reduce or avoid the use of problematic traditional preservatives. These INOLEX systems incorporate a novel chelating agent, caprylhydroxamic acid (CHA), which has been proven to work synergistically with other ingredients such as medium chain (C6-C10) terminal diols/esterdiols/etherdiols and aromatic alcohols. These systems have already found wide uses in virtually all cosmetic forms. One significant advantage of these systems is that they are effective in higher pH formulations (6.0 and higher.)

Hurdling Wet Non-Woven Substrates

A particular challenge has been the identification of ingredients that can be used in the hurdle technology approach for solutions and emulsions in non-woven substrates. Typical applications are baby wipes, moisturizing wipes, makeup remover wipes, and the increasingly popular moisturizing facial masks. In addition to the need for cold processability, there must be no adverse interactions between the hurdle technology components in the solution and the substrate. Some of these interactions are the destabilization and deactivation of the components after application to the substrate, component fractionation in the wipes stack (the “chromatography effect,”) and substrate discoloration over time.

INOLEX has commercialized two cold-process alternative preservation systems, Spectrastat OL (INCI: Caprylhydroxamic Acid (and) Capylyl Glycol (and) Propanediol) and Spectratstat OEL (INCI: Caprylhydroxamic Acid (and) Caprylyl Glycol (and) Ethylhexylglycerin (and) Propanediol), that are optimal for non-woven applications and are based on CHA technology.

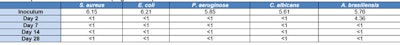

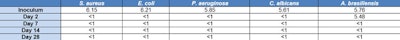

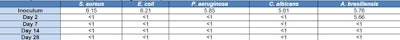

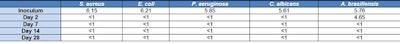

These systems have been thoroughly tested by applying a test formulation containing a simple nonionic, high water content surfactant system typically employed for baby wipes (see Formula 1) to the most popular non-woven substrate types. Exemplary results are provided below on Airlaid (80% wood pulp, 15-17% PE/PET Bico fiber, 3-5% latex adhesive) in Table 1 and Table 2 and Spunlace (35% viscose, 65% PET) non-woven substrates in Table 3 and Table 4. The methodology used was challenge testing, as specified per the Personal Care Product Council's M-5 guidelines. The results show that these formulations pass all common criteria for preservation efficacy.

INOLEX currently provides a variety of alternative preservation solutions for the most challenging problems, and provides formulation assistance as well. Connect with us! For more information on current products and new product releases, please visit www.inolex.com or email us at [email protected].

Disclaimer:

The above paid-for content was produced by and posted on behalf of the Sponsor. Content provided is generated solely by the Sponsor or its affiliates, and it is the Sponsor’s responsibility for the accuracy, completeness and validity of all information included. Cosmetics & Toiletries takes steps to ensure that you will not confuse sponsored content with content produced by Cosmetics & Toiletries and governed by its editorial policy.