The U.S. Food and Drug Administration (FDA) has liberalized the compounding of alcohol-based hand sanitizers, where any registered compounder can blend, package and sell these products as long as they follow the published formulas and guidelines for industry.

This move falls under the accord published on March 20, 2020, (reference 21 CFR10.115(g)2) titled, “Policy for Temporary Compounding of Certain Alcohol-Based Hand Sanitizer Products.”

Many personal care product compounders, “registered” or not, are jumping into this market. I like to think most are doing so out of public service, though I suspect profit motive is the impetus for some. In either case, I have noticed formulas and notions posted online that betray the malfeasance of many attempting to do so. Let’s clear up the math, the processing and the final product here to upend the mistakes and mischief.

Mass Conversion

It is telling how many compounders simply do not understand activity and mass conversion factors. This especially glaring since the FDA missive states, on Page 3, “The compounder must take care…to insure the correct amount of active ingredient is used.” The FDA did not make it easier by mandating the concentrations in volumetric measure (% v/v) instead of mass (% w/w), inferring those “registered compounders” will be mixing these solutions in a pharmacy or laboratory, not an industrial compounding facility. To any company that has been compounding with ethanol (SDA) and hydrogen peroxide into sanitizers, mass conversion is the obvious first step.

Most in our personal care industry use 190 proof SDA, which is 95% ethanol, for its lower vapor pressure and safety. We all use the standard 35% hydrogen peroxide FCC (Food Chemical Codex) or CG (Cosmetic Grade) solution. That peroxide activity is actually closer to 34% now that U.S. Homeland Security scrutinizes all companies buying a concentrate greater than 35%, which ruled out the standard 50% solution we used years ago.

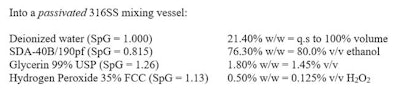

To obtain the published FDA parameters of 80% v/v ethanol and 0.125% v/v hydrogen peroxide, in an actual mass formula, relative densities must be factored. Here is the formula reiterated, rounded to three significant digits:

Formula 1

Formula 1Mix well until a uniform clear liquid. Specific Gravity @ 25°C in range of 0.860 (hydrometer). No assay of ethanol necessary, just check and record that density as a quality control step. My conversion for hydrogen peroxide volume is based on a density of 100% peroxide, which would measure SpG 1.40 if it were safe to do so. Therefore, to gain 0.125% volume: (0.35 *0.50) = 0.175% w/w, and 0.175 ÷ 1.40 = 0.125 %v/v.

Mass conversion of ethanol as SDA-40B can be checked for 100 volume of sanitizer: [(76.3 * 0.860) ÷ (0.815)] = 80.5% v/v (80 gallons or liters). There is still the proof factor to deal with, where this may comprise 76% ethanol depending on source and lot. I factor a variance range of ± 5.0% of mean value, so use 190 or 200 proof SDA and don’t bother changing the formula each time. 76% ethanol is still well over the established minimum effective range of 60.0% ethanol.

Many active voices online are adamant about testing product pH, but that is irrelevant as long as you passivate your stainless steel and manage additions well. The density measurement validates alcohol content and that is the more important parameter. I recommend SDA 40B as the best one to use, since it is denatured with Bitrex and t-butyl alcohol. Children won’t drink it when they find that hand sanitizer bottle in the house. With alcohol supplies so unsteady in most countries today, the grade used may be considered flexible.

'The compounder must take care…to insure the correct amount of active ingredient is used.'

Passivation

If you have a clean glass-lined or fiberglass mixing vessel, you may skip the passivation step.

Neophytes may ask: Passivation? What’s that? When you incorporate peroxygens into a batch using stainless steel equipment, you need to passivate, which is to scavenge the free metal ions at the surface of the vessel and transfer equipment. Failure to do so leads to faster reduction of the peroxide to water by free metal ions, diluting its virus-sanitizing power, and at only 0.125%, you do not have much to start with, either. Dilute solutions of nitric acid or citric acid covering all stainless steel surfaces for 90 min, after a thorough cleaning with an alkaline wash, will do the job.

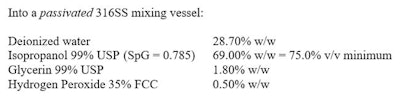

The isopropanol (IPA) version may use only the standard 99% solution. It also carries a cost of goods double that of the SDA formula:

Formula 2

Formula 2Mix well until a uniform clear liquid. Specific Gravity @ 25°C: in range of 0.860 (hydrometer).

Taking Liberties

There is no latitude in either formulation, and this is the only means by which these compounders can produce, package and sell these products under the FDA guidelines of March 20th without needing to register as a drug manufacturer. The marketer needs only to follow the Drug Facts labeling guideline shown on Pages 5–8 of the publication.

These temporary formulations were designed to spray onto the hands. I've found that a turret-seal dispensing cap with orifice size of 2 mm can work to dispense these liquids at a slow enough rate for hand utility if sprayers are difficult to procure. Container construction should be PETE, though HDPE can do for short-term use. For shipment, use ground transport only; these are combustible liquids.

Attempting to gel either formula or add fragrance or other components is a case of, ironically, drug product adulteration.

“The formulator-compounder who ‘gets creative’ with the guidelines will then need to follow the same FDA cGMP protocols for OTC drug production, registration and alcohol assay as we’ve done [for] years for our hand sanitizer gels,” adds Brian Corcoran, president of Solo Laboratories.

Certainly don’t add more glycerin, as the World Health Organization footnote cites the germicidal activity decrease when glycerin is added to isopropanol. That holds true with the ethanol formula as well. Glycerin makes an azeotrope with alcohols, affecting their activity. This is the reason we use ethoxylated refatting agents in these alcohol formulas, such as PEG-10 dimethicone and PEG-7 glyceryl cocoate.

I’ve also seen aloe vera mentioned online as a worthy addition: this is not advisable. Like so many ingredients, aloe vera is not peroxide stable. If anything, hold the aloe and go long on peroxide if killing COVID-19 is your goal. No doubt some labelers are getting creative with these formulas to gain a marketing edge. Fortunately for them, our FDA has larger issues to contend with such as getting more COVID-19 test kits and ventilators manufactured. Both are medical devices manufactured and regulated under the aegis of FDA. Regulating errant alcohol formulators is not likely to be on their priority list for the near future.

Harmonizing Northward

Finally, if the North American formulator-compounder is looking to harmonize with the interim deregulated sanitizers of Health Canada, these formulas are already there. Health Canada considers alcohol-based hand sanitizers as Natural Health Products, and hydrogen peroxide is listed within their database as pre-cleared for first aid. The other chemical agents for personal care hand sanitizing are not part of this interim deregulation, just as they aren’t with the U.S. policy. These include benzalkonium chloride, benzethonium chloride, chlorhexidine and my personal favorite, chloroxylenol.

To distribute in Canada, you, the compounder, still need to file for a site license, identify a qualified quality assessor (read: chemist), follow labeling guidelines and preferably furnish a certified facility cGMP audit to the standards of ISO22716. For more details on that, I direct you to read the brief and links published in the Cosmetics & Toiletries article of March 30, 2020: “Health Canada Expedites Alcohol-based Hand Sanitizer Distribution.”