Caramel has been used in the personal care industry as a natural colorant for many years.1 As the demand for natural personal care products continues to grow, the interest in caramel as a personal care colorant also has grown. Caramel is an approved colorant in the United States and Europe,2 yet little is understood about how the performance of caramel can differ in personal care formulations. The objective of this article is to provide a simple understanding of the different classifications of caramel and how they can be applied in personal care formulas.

All caramels are not the same. They are divided into four classes: plain or caustic caramel (Class I); caustic sulfite caramel (Class II); ammonia caramel (Class III) and sulfite ammonia caramel (Class IV). Caramel colors are amorphous, brownish materials resulting from the carefully controlled heat treatment of food grade carbohydrates in the presence of small amounts of food grade acids, alkalis or salts. The ingredients or raw materials used in the preparation of caramel color in the United States are listed in the Standard of Identity for Caramel (CFR 21, 73.85).2

The chemistry of caramelization is complex and difficult to explain in brief. Modern caramel color production is carried out in a heat controlled, closed vessel where a caramelization reaction occurs. In this reaction, the sugars, i.e. large carbohydrate molecules, are dehydrated, then either reduced in size to simple sugars under the influence of acid, heat and/or pressure; condensed or recombined; or polymerized into complex color molecules of varying molecular weight.

Since caramel is a complex aggregate of degraded sugars, it is also difficult to illustrate using simple structural terms. Caramel can be considered a reduction of complex carbohydrates to smaller carbohydrates that are then combined into larger polymeric colored ingredients and by-products. Similar examples of complex by-products created by mixing reactant products include roasted coffee and broiled meats.

Caramel Properties

The caramel process reaction end-point is determined from a combination of specific gravity, pH and viscosity. Caramel color is a complex mixture of charged compounds, some of which are in the form of colloidal aggregates. Caramel usually is a dark brown to black liquid or solid having an odor of burnt sugar and a somewhat bitter taste.3, 4 Caramel colors have isoelectric points and pH levels varying over a wide range.

The colloidal charge of caramel is strongly influenced by pH, so by changing the pH of caramel solutions, the isoelectric point where the charge is neutralized can be reached. Further pH adjustments will cause the charge to switch to the opposite polarity.

Consideration must be given to the charge of the caramel color selected. In coloring a product with caramel, the particles of the caramel color must have the same charge as the colloidal particles of the product to be colored. If a caramel color is put into a colloidal solution with oppositely charged particles, the particles will attract one another, form larger insoluble particles, and settle out. For example, a soft drink contains negatively charged colloidal particles; therefore, a negative caramel color should always be used.

Conversely, beer contains positively charged proteins. Therefore, the addition of negative-charged caramel creates a cloud that agglomerates into particles large enough to precipitate quickly. For this reason, positively charged, beer-stable caramel should be selected. In personal care, positively charged caramel would be utilized in conjunction with positively charged ingredients such as cationics or proteins.

Negatively charged caramels work well in whiskeys, wines, rums and liquors.4, 5 Wines clarified using gelatin and tannic acid require enough tannic acid to remove the entire gelatin, otherwise the remaining positively charged gelatin and negatively charged caramel will precipitate and be removed during the filtration process, making the wine perceptibly lighter in color. Similarly, negatively charged caramels would be utilized in personal care in conjunction with negatively charged formulations such as anionic surfactant systems.

Color Intensity

The color intensity of caramel is defined as the absorbance of a 0.1% w/w solution of caramel color solids in water in a 1-cm cell at 610 nm. Percent solids are used in the calculation. The color intensity of caramel is dynamic and will lighten over time during shelf storage. This, and the percent of caramel added, affects the color of the final formulation.

A little caramel goes a long way to develop an intense caramel to dark brown colored formula. However, process variations in the production of caramel can cause deviations in the final resultant color. Therefore, it is critical to develop tight specifications on the color of caramel to minimize color variation in the final formulation.

It should also be noted that caramel has a defined shelf life and little is known about how caramel degradation over the long term can affect the end color of a finished product, or under what storage conditions this change occurs. Thus it is recommended that formulators purchase only the amount of caramel they require for a one-year period since its color changes and viscosity increases with age. In addition, the caramel color in a two-year-old drum could be significantly darker than that in a fresh drum of the same product.

Caramel Classification

As noted, caramels are divided into four classes, described below, that differ in colloidal charge, color intensity, stability, manufacture and use, as shown in Table 1. All grades of caramel are used in personal care products, with the more popular ones being from class II and class III.

Class I: Plain caramel or caustic caramel is prepared by heating carbohydrates with or without acids or alkali. Ammonia or sulfite compounds are not used and therefore this class requires the fewest reactants; in addition, this class is not stable at pH levels < 3.0. The colloidal charge of this group is slightly negative. Finally, this class has a 62–77% solids content and is generally used at a level of 0.01–0.12%.

Class II: Caustic sulfite caramel is prepared by heating carbohydrates with or without acids or alkali in the presence of sulfite compounds. No ammonium compounds are used for this group, and the colloidal charge is strongly negative. Class II caramels have a 65–72% solids content and are generally used at a level of 0.06–0.10%.

Class III (coded 10199): Ammonia caramel is prepared by heating carbohydrates with or without acids or alkali in the presence of ammonium compounds; no sulfite compounds are used. This class of caramels is stable at a pH level < 3.0 and it has a strongly positive colloidal charge. Its solids content is 53–83% and it generally is used at 0.08–0.36%.

Class IV: Sulfite ammonia caramel is prepared by heating carbohydrates with or without acids or alkali in the presence of both sulfite and ammonium compounds. This class is pH stable and has a strongly negative colloidal charge. The solid scontent is 40–75% and the use level is generally 0.1–0.6%.

Formulating with Caramel

As noted, the isoelectric point is the pH at which the colloidal charge is neutral, and this is established by both the ingredients and the caramel coloring process. A negatively charged caramel color has a pH higher than its isoelectric point. The methods used to determine this neutral point are based on the mutual attraction of particles with opposite charges. The procedure generally employs solutions with a known colloidal charge to detect the pH at which the charge of the caramel color particles changes.

It is suggested that the isoelectric point of a formula be determined before using caramel liquids. For example, caramels in Class III have a charge that is usually positive up to around pH 5, then the isoelectric point will be between pH 5 and 7 depending on the product; above this pH, it will be negative. In contrast, Class IV caramels have a negative charge above pH 2 and the isoelectric point will usually be between pH 0.5 and 2; below this pH, it will be positive.

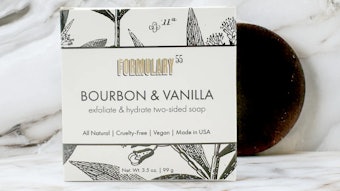

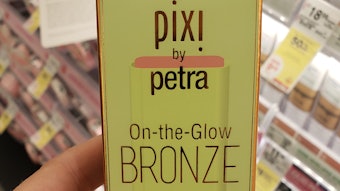

As previously mentioned, caramel’s role in personal care is as a colorant and several products recently launched to the marketplace that contain caramel exemplify revived interest in this natural ingredient.

References

- MA Gelis, Action de la chaleur sur les substances neutres organiques; Edu du caramel et des produits torrefies, Ann Chim Phys (3) 52:352 (1858)

- Federal Register Volume 59, Number 24, Title 21, Sec. 7385 (Friday, February 4, 1994), available at www.gpo.gov/fdsys/pkg/FR-1994-02-04/html/94-2472.htm (accessed Apr 28, 2010)

- DD Williamson, Basics of caramel colors, available at www.caramel.com/a-156-297-The-Basics-of-Caramel-Colors.aspx (accessed Apr 8, 2010)

- W Kamuf et al, Overview of caramel colors, Cereal Foods World, American Association of Cereal Chemists 48(2) 64–69 (Mar/Apr 2003), available at www.aaccnet.org/cerealfoodsworld/pdfs/W03-0205-01F.pdf (accessed Apr 8, 2010)

- Joint FAO/WHO Expert Committee on Food Additives (JECFA), Food and Nutrition Paper 52, Addendum 8 (Nov 2000), available at www.grokfood.com/jecfa/additive_0800.htm (accessed Apr 8, 2010)