Testing the efficiency of sun protection evaluation is compulsory for sunscreen development and labeling, whatever the geographic market. The current worldwide impetus is toward in vitro methods, which are typically less expensive, faster and increasingly being considered reliable, once several parameters are mastered.1-8 Until now, however, only in vivo standards9, 10 have been published, and they are considered the “gold” value. Clearly, in vitro methods based on these same qualities could be a real alternative for ethical, practical and economical reasons.

Standard in vitro tests are based on UV transmission assessment through a thin film of sunscreen spread over a suitable substrate. This method seems simple, but several parameters must be controlled to assure reliable results. Obviously, one of the most important parameters is the substrate itself, which must be reproducible in order to reduce variations in SPF results.11, 12 Indeed, the reproducibility of substrate roughness is critical and a primary concern for assuring reliable in vitro UV values, as has previously been demonstrated.2 Furthermore, recent methods and standards13 recommend plates with strictly controlled topographic parameters to ensure the reliability of results. Beyond current standards and methods, the future harmonized method for in vitro SPF assessment must comply with two points: reproducibility and accuracy with in vivo values.

Until now, two types of polymethylmethacrylate (PMMA) substrates, molded and sandblasted plates, have been used, but it has been shown that the roughness of molded plates has higher reproducibility than sandblasted plates. Initially, sandblasted plates were produced using an uncontrolled manual sandblasting process on a large plate, before cutting the plate into several pieces. Unfortunately, this process leads to variability and poor reproducibility. In order to reduce this variation, the authors focused on improving the sandblasting process, as described here. For this, all previously identified variables that influence the results were controlled—including pressure, distance between plates and the sand gun, abrasive grain size and type, passing time and mechanical process. The aim of this study was to compare plates sandblasted by the previous method with plates treated using this new method to improve in vitro SPF repeatability and reproducibility.

Materials and Methods

Substrate selection: Two types of PMMA plates with one face roughened were purchased from suppliers: previously sandblasted PMMA platesa measuring 50 x 50 x 3 mm, and the newly sandblasted PMMA platesb measuring 47 x 47 x 1.5 mm.

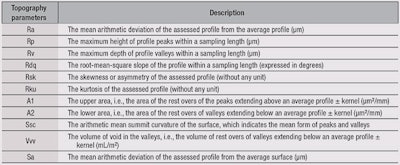

Topography assessment: Surface topography parameters were measured by non-contact surface topographic analysisc on a surface area of 10 mm x 5 mm, in 15-µm intervals and at a speed of 100 steps/sec. The same area was measured for all samples (4 plates per batch). This set-up was equipped with an XY plane spatial resolution of 0.1 µm and a confocal chromatic sensor with 3.39-nm vertical resolution (Z axis). Interpretation of the measurements was conducted by microtopography softwared following the sequence: filling unmeasured plots by extrapolation, making surface adjustments and averaging the profile obtained from the surface’s division (for 2D parameter assessment). From these topography results, different topography parameters were selected (see Table 1) according to a previous study11 and typical standards for in vitro UVA-PF assessments.13

Sunscreen evaluation: Thirty-four sunscreen products of various types were chosen for this study. These were applied using an automated syringe to spread them across each plate surface at a rate of 1.2 mg/cm2 for both the previously5-12 and newly sandblasted plates. To ensure a correct application rate, the automated syringe was weighed before and after product application. Immediately after weighing, the sunscreen product was spread over the entire surface. During spreading, the temperature was controlled by a devicee that maintains the temperature at the surface of the plate, 25°C in this study. After the product was spread, the sample was allowed to dry and settle for 15 min in the dark for self-leveling, again at 25°C. After drying, UV transmittance measurements were performed on the samples by means of a transmittance analyzerf. Before tests, it was calibrated by both specified standardsg and the linearity/additivity by calibrated reference standard PMMA platesh to which UV filters were incorporated. Blank transmittance was obtained by covering a PMMA plate with a film of white petrolatum. Three different plates were used for each tested product, and nine UV transmission spectras were recorded every nanometer in the 290–400 nm range for each plate at the different application locations.

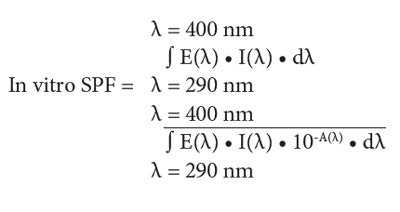

By means of sunscreen UV transmittance measurement, T(λ), the in vitro SPF could be calculated by combining the UV light attenuated by the sunscreen film, the erythema action spectrum (as required according to ISO 24443:2012) and a relevant solar emission spectrum according to Equation 1:

Eq. 1

where E(λ) is the relative effectiveness of UVR in producing erythema in human skin according to the erythema action spectrum (CIE, 1987) at wavelength λ; I(λ) is the spectral irradiance received from the UV source at wavelength λ—in this case, calculating results from UV sources representing midday midsummer sunlight, i.e., UV spectra received at the earth’s surface in Zenithal conditions; A(λ) is the monochromatic absorbance of the sunscreen layer at wavelength λ, with A(λ) = -log [T(λ)]; and d(λ) is the wavelength step, equal to 1 nm in this study.

Finally, the in vitro SPF reported in this study is the arithmetical mean of the 27 in vitro calculated SPFn values for each location based on three tested plates. The range of variation of in vitro SPF values is characterized through standard error mean (SEM) and coefficient of variation (CV).

Results and Discussion

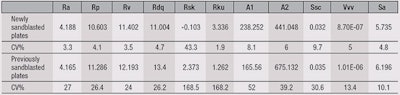

Topography results: The first step of this study was to evaluate topography reproducibility between plates at the same measurement area. For this, the authors selected 10 different batches and made measurements, the results of which are summarized in Table 2—the representation of coefficient of variation is shown in Figure 1.

Regarding the roughness level, in both cases, a close value was obtained regardless of the topographic parameters. For example, the average Ra parameter was approximately 4.188 µm and 4.165 µm, respectively, for the previously and newly sandblasted plates. However, for topography variation, results showed better reproducibility for the newly sandblasted plates regardless of the roughness parameter selected. The average variation for all roughness parameters was approximately 8.5% for the newly sandblasted plates, compared with 53.2% for the previously sandblasted plates.

In order to calculate the level of homogeneity, a Principal Component Analysis (PCA) was performed including all results (see Figure 2), with X axis PC1 = 35.94% mainly supported by the topographical parameters Rdq, A1, A2, Sa and Ssc (as listed in Table 1); and Y axis PC2 = 32.43% mainly supported by Rp, Rv, Ra, Rsk, Rku and Vvv. In this graph, the closer the plots, the better the reproducibility. As noted previously, the variation within the same plates was clearly better for the newly sandblasted plates than for the previously sandblasted plates.

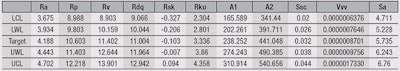

As was proposed in a previous paper,8 a control chart was developed in order to follow the quality of the different batches of the newly sandblasted plates. This control chart uses a set of target, upper and lower warning limits (UWL and LWL), which include a confidence interval of 95% (based on the normal distribution hypothesis), in addition to upper and lower control limits (UCL and LCL) that include a confidence interval of 99.7%, also based on the normal distribution hypothesis. This control chart (see Table 3) was used to accept or refuse a batch with a random control during a batch manufacture, combined with the Western Electric rules for detecting “out-of-control” or non-random conditions on control charts. If two or three points in a row are beyond a warning limit and if one point is beyond the control limit, the batch must be rejected.

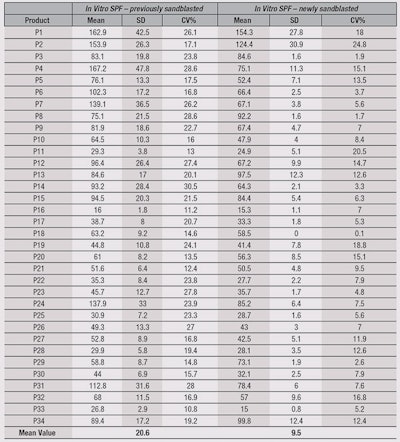

In vitro sun protection evaluation: Next, the in vitro SPFs for all 34 products were evaluated on the two different sandblasted substrates. Detailed results are shown in Table 4. Concerning repeatability of results, a box plots graphic, shown in Figure 3, was used to represent the in vitro coefficient of variation according to substrates. By means of these univariate representations of quantitative data samples, it is clear that the newly sandblasted plates give better results for less variability than the previously sandblasted plates. Indeed, the mean coefficient of variation according to each substrate was approximately 20.6% for the previously blasted plates due to their process of manufacture; this value was only approximately 9.5% for the newly sandblasted plates. In other words, the latter provided roughness homogeneity to reduce test results variances. Obviously, it also seems logical to consider the impact of topography reproducibility on other values related to sun protection, such as critical wavelength, in vitro UVA-PF, etc.

Furthermore, it has already been demonstrated that the previously sandblasted plates often overestimated in vitro SPF values, compared with in vivo values,12 which can lead to misinterpreted sun protection efficiency. With lower in vitro SPF results, in a majority of cases, the newly sandblasted plates reduce this overestimation, which could lead to better in vitro/in vivo correlation. Nevertheless, as presented earlier in this paper, the prior condition of any methods is reproducibility before correlation, and this was the aim of the newly sandblasted plates.

Conclusion

In vitro SPF assessment reaches a high technical level, ensuring reproducibility of results, if several key parameters are mastered. Indeed, recent studies focused on reproducibility and improved reliability of in vitro sunscreen testing. While molded and sandblasted substrates are used worldwide, only molded plates, until now, have been proposed in international in vitro methods due to their high level of reproducibility. In the present study, the new sandblasting process allows for very high reproducibility in roughness parameters and in vitro SPF values. Indeed, the variability of in vitro SPF due to substrate was reduced by about half using the newly sandblasted plates. Furthermore, it has been demonstrated that only one topographic parameter is not enough to ensure reproducibility, and clearly several topographic parameters are required. Thus a control chart based on several topographic parameters has been developed in order to accept or refuse a batch, allowing for a higher level of quality. In order to ensure worldwide reproducibility of international in vitro standards or methods, strict control of topographic parameters level and variability is compulsory.

Moving forward, as in vitro methods can be now considered as reproducible with respect to different key parameters, including substrates (molded and sandblasted), the authors expect to extend the investigation to in vitro/in vivo correlation by means of a multiple substrate solution.

References

- L Fageon, D Moyal, J Coutet and D Candau, Importance of sunscreen products spreading protocol and substrate roughness for in vitro sun protection factor assessment, Intl J Cosmet Sci 1-13 (2009)

- L. Ferrero, M Pissavini, A Dehais, S Marguerie and L Zastrow, Importance of substrate roughness for in vitro sun protection assessment, IFSCC 9(2) 1-13 (Apr/Jun 2006)

- S Miksa, D Lutz and C Guy, UV transmission assessment: Influence of temperature on substrate surface, Cosm & Toil 128(7) 484-494 (Jul 2013)

- J Staton and C Dennyson, Issues at the margins, Validation of sunscreen in vitro UVA test measurement, for FDA, COLIPA and ISO, H&PC Monographic Supplement Series: Focus on Sun Care (3) (2011)

- M Pissavini et al, Determination of the in vitro SPF, Cosm & Toil 118(10) 63-72 (Oct 2003)

- S Miksa, D Lutz and C Guy, In vitro UV testing—Robot vs. human spreading for repeatable, reproducible results, Cosm & Toil 128(10) 742-752 (Oct 2013)

- S Miksa, D Lutz and C Guy, Influence of pressure during spreading on UV transmission results, Cosm & Toil 128(9) 822-832 (Nov 2013)

- N Cariou and D Lutz, Sunscreen in vitro SPF determination inter and intra comparison tests between several measurement instruments, HP&C Monographic supplement series: Compendium on sun care 7(3) (Jul/Sep 2012)

- Cosmetics—Sun protection test method—In vivo determination of the sun protection factor, (SPF) ISO 24444 (2010)

- US FDA, Department of health and human services, Sunscreen drug products for over-the-counter human use, Final Rule 21 CFR parts 201 and 310, Federal Register 76 (117) (Jun 17, 2011)

- M Pissavini, S Marguerie, A Dehais, L Ferrero and L Zastrow, Characterizing roughness: A new substrate to measure SPF, Cosm & Toil 124(9) 56-64 (Sep 2009)

- S Miksa, D Lutz and C Guy, In vitro/vivo SPF correlation and repeatability according to substrate, Cosm & Toil 128(09) 648-657 (Sep 2013)

- Cosmetics–Sun protection test method–Determination of sunscreen UVA photoprotection in vitro, ISO/FDIS 24443 (2012)