In today’s global personal care market- place, consumers have specialized needs based on function as well as fashion. In response, formulators strive to develop unique, high-performance products to meet rapidly evolving trends. Ingredients that combine multiple benefits offer potential for differentiated solutions while making formulation simple and more cost-effective. Among the array of product forms, cosmetic sticks are practical and easy to use. However, they can also present formulation challenges in terms of structure, stability and aesthetics.

A Multifunctional Solution

Hyperbranched polyalphaolefins (HBPs) commonly are used to form flexible films and impart gloss. Known by their INCI designation as synthetic wax, HBPs also have film-forming properties that allow them to act as conditioners and moisturizers. Their distinctive branch-on-branch structure enables them to lower pour points, modifies structure and improves formula stability, making HBPs useful for a number of personal care applications ranging from lipsticks to lotions.

Figure 1 illustrates the structure of these materials, which can be designed in numerous branch lengths.

Depending on branch length and associated molecular weight, HBPs exist as low-melting solids or as liquids, which have the added advantage of making them cold-processable.

Polyethylene and other highly crystalline waxes typically are used in stick formulations to provide efficient structuring and to prevent syneresis that can be associated with natural materials such as beeswax, carnauba wax and candelilla wax. However, the use of polyethylene results in high pour points and a matte finish—issues that can be resolved by adding HBPs.

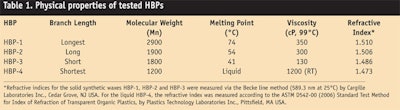

Four HBP productsa, designated in this article as HBP-1 through HBP-4 according to their branch lengths from longest to shortest, were evaluated in anhydrous stick formulations where polyethylene was the main structurant for commonly used oils. The oils were mineral oil, isododecane, isopropyl palmitate, C12-C15 alkyl benzoate and safflower oil. In addition to their wide use in personal care formulations, these five materials were chosen to illustrate polar and nonpolar examples, and to include one natural ingredient. Table 1 summarizes the properties of these HBPs.

In the tests described here, the control in each case was a polyethylene/oil base (Formula 1 and Formula 2). If the oil was isopropyl palmitate, C12-C15 alkyl benzoate, mineral oil or safflower oil, polyethylene was added at 12%. In the case of isododecane, 30% polyethylene was added to achieve an appropriate stick structure. The various HBPs were added at 5%, which is an average level used in the industry. In actual personal care formulations, use levels for the solid HBPs -1, -2 and -3 are typically less than 10%. In the case of HBP-4, use levels may be 5% or higher because of the liquid nature of the material.

Lowering Pour Point

Research has shown that polyalphaolefins can act as pour point depressants by modifying crystal shape and size, as well as flow characteristics.1–2 This attribute can also provide advantages in personal care applications, including safer handling, easier mixing and lower energy costs.

Pouring temperature is the lowest temperature at which a molten wax mixture can be easily dispensed. Blends of polyethylene in various oils were tested as controls and the impact of adding 5% of the HBPs was evaluated. The test was conducted by solubilizing the waxes in the oil and slowly cooling the specimen under observation. The pouring temperature was recorded at the point where the mixture was still homogeneous and fluid, but the authors observed a sharp increase in viscosity. Thereafter, viscosity continues to increase until the specimen reaches the congealing point, or “no flow” condition.

In this study, HBPs were found to depress the pour points for high-melting crystalline waxes (Figure 2).

In combination with mineral oil, HBP-1 depressed the pouring temperature by a full 10°C, to 62°C. Although, as described later, this combination is not stable on a long-term basis, the addition of HBP-3 and HBP-4 at 5% lowered the pouring temperature nearly as much, to 63°C and 64°C respectively, in mineral oil; both combinations were found to be stable. In the case of isopropyl palmitate, HBP-3 lowered the pouring temperature by 9°C.

The present studies on HBPs as well as research noted in the literature1–2 suggest the pour point depressant mechanism of HBPs is influenced by the average side chain length, the distribution of side chains and the characteristics of the oil in the mixture. The HBPs modify the shape and size of the waxy hydrocarbon crystal to slow agglomeration and lower the effective pouring temperature. SEM photos (Figure 3) illustrate the changes in the wax crystals formed.

Lowering pouring temperature adds another dimension of formulating flexibility by offering greater protection for volatile ingredients such as fragrance, isododecane, volatile active ingredients or combinations of ingredients that may be sensitive to heat.

Gloss Improvement

HBPs can enhance gloss in anhydrous systems. To evaluate this effect, gloss measurements of the samples were conducted using a glossmeterband following a standard method3 for specular gloss.

A specimen of each test formula (Formula 1 and Formula 2) weighing 0.5 g was applied to a 4.5 x 5.5-inch test surfacec with a circular motion for 1 to 2 min, and a minimum of three gloss readings were taken at an angle of 60 degrees.

Polyethylene typically imparts a matte appearance. However, in anhydrous systems, HBPs provide gloss even in matte bases. Enhanced gloss primarily is the result of the highly branched characteristics of the HBP. This structure results in high refractive indexes (RIs). For example, the tested HBPs all showed RIs in the range of 1.473 to 1.510 (Table 1), comparing favorably with the 1.46 value achieved by the widely used cosmetic industry glossing agentsd phenyltrimethicone and hydrogenated polyisobutene.

In most cases, gloss measurements based on the addition of various HBPs to the polyethylene/oil blends showed noticeable improvement versus the blends alone (Figure 4).

In additional studies4 with prototype formulations, the HBP allowed greater pigment loading and aided wetting and dispersion, resulting in highly stable systems. Micronized pigments and organic lakes dispersed in HBPs also imparted higher gloss and color strength without change of hue compared to nondispersed pigments and lakes.

Structuring and Stability

Evaluations of the structuring capability and stability of the HBPs were conducted, again using Formula 1 and Formula 2. In these evaluations, stability is defined as the lack of syneresis—i.e., no oil bleed—in the mixture.

The HBPs were evaluated for structuring capability and stability. The anhydrous systems of Formula 1 and Formula 2 were cooled overnight in covered containers. On the following day, a minimum of three penetration values were recorded using a 35-g cone needle and a penetrometere.This approach measures the distance a cone penetrates into the test material in five seconds; thus, the lower the measurement, the harder the material. Measurements of hardness were recorded in decimillimeters (dmm) at various sections within the sample using a standard protocol.5 Figure 5 illustrates the results of this test.

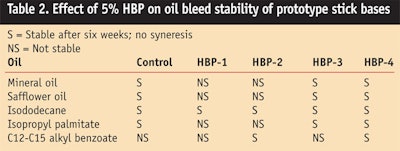

Overall, HBP-2 and HBP-3 performed best in the systems that were identified as stable, i.e., without syneresis for more than six weeks (Table 2).

Each sample was evaluated for six weeks at room temperature, at 49°C and through three freeze-thaw cycles.

In some cases, the addition of HBP softened the sample. For example, the two HBPs with the long branch length (HBP-1 and HBP-2) softened the systems with mineral oil, safflower oil and isopropyl palmitate and made them unstable, an effect not seen in these same systems when the two HBPs with short branch lengths were added. It is important to select the correct branch length of HBP for specific formulation types or requirements. In general, HBPs with shorter branch lengths result in greater stability, while longer branch lengths tend to reduce structuring effects.

The SEM photographs in Figure 3 show that the addition of an HBP creates a structure that is more uniform with smaller wax domains. This effect suggests the HBP acts as a compatibilizer between the oil and polyethylene to help disperse the polyethylene in the oil, with the result being a smaller crystal size and the entrapment of oil within the crystalline matrix.

With its longest branch length, HBP-1 is effective at low levels for modifying the crystalline characteristics of the polyethylene/oil system; however, it has an optimum use level. In contrast, the SEM photographs in Figure 6 illustrate how an excess of the HBP can affect the crystalline matrix of polyethylene. Here, the compatibilizing effect is too great, resulting in a crystal size that is too small and not stable. In this example, decreasing the level of HBP-1 from 5% to a level less than 5% might improve its oil-binding capabilities, resulting in a more stable system.

In general, the degree of compatibilization is related to both branch length and type of oil. The longer the chain length of an HBP, the more it typically decreases structuring capabilities. However, oil binding may also be affected depending on branch length. For this reason, it is important to assess these parameters with the specific ingredients used in individual applications.

Summary

Given the specific concentrations of polyethylene and HBPs in the present studies, it is possible to make some general statements related to pouring temperature, gloss and stick structure. These results may help to serve as a screening tool during ingredient selection. However, formulators should carefully evaluate ingredients based on their specific formulations and applications.

Mineral oil: Among the stable systems shown, HBP-3 and HBP-4 were best for depressing pouring temperature and increasing gloss in mineral oil. They were also best for increasing hardness, with improvements of 19 and 22 dmm, respectively.

Safflower oil: HBP-2 was found to be the most effective for reducing pouring temperature—from 72°C to 62°C—although this system did not show long-term stability. Among the stable systems, the HBP-4 wax performed best. The best material for enhancing gloss and hardness was HBP-3, with an increase of 12 points for gloss and a 20 dmm improvement in hardness.

Isododecane: All four HBPs reduced pouring temperature slightly, with HBP-1 performing best for a drop in temperature of 3°C. In terms of gloss, HBP-1 again was best, raising gloss by nearly 30 points. The addition of HBP-4 resulted in a slight decrease of gloss; HBP-3 was best for enhancing hardness, with a decrease of 22 dmm.

Isopropyl palmitate: Among the stable systems, HBP-3 performed the best for reducing pouring temperature, with an improvement of 9°C. This wax also showed the best enhancement for gloss. All HBPs softened the stick base containing isopropyl palmitate.

C12-C15 alkyl benzoate: Among the systems showing long-term stability, HBP-4 was shown as the best for lowering pouring temperature. HBP-2 was best for enhancing gloss and hardness in the stable systems.

Conclusions

The results of several evaluations indicated that HBPs can lower pour points, with chain length and oil type as factors that resulted in different performance. The results also indicate that stick stability is more likely to be compromised by the incorporation of longer branch length HBPs—in these tests, HBP-1 and HBP-2. HBPs can also increase gloss and improve formula stability. Two of the polymers tested also improved hardness in most of the oils tested. While demonstrating new benefits, the results of this study have potential as a screening tool to help formulators focus on useful combinations of materials for specific applications. This approach may help reduce development time and cost.

The anhydrous sticks discussed in this article and illustrated in Formula 3 have obvious applications in the color arena in product forms such as lipsticks, lip balms, foundation sticks, concealers and eye shadow sticks. It should be noted that the applications extend to other areas of personal care, such as sunscreen sticks, AP sticks and facial sticks, and beyond to laundry sticks for the household and acne control stick products in the pharmaceutical area. Overall, HBPs can be valuable ingredients to help formulators create novel, high-performance personal care, household and pharmaceutical products that meet changing global needs.

References

1.US Pat 5,641,736, Synergistic pour point depressant combinations and hydrocarbon lube mixtures, TR Forbus, assigned to Mobil Oil Corp. (Jun 24, 1997)

2.C-X Xiong, The structure and activity of poly-alphaolefins as pour point depressants, Lubric Eng 196-200 (March 1993)

3.ASTM D 523-89, Standard Method for Specular Gloss (1999)

4.Unpublished data supplied by Kobo Products, South Plainfield, NJ USA (2007)

5.ASTM D 937-77, Standard Test Method for Cone Penetration of Petrolatum (2004)