The world of cosmetic formulation has changed. Today, there is a need for increasingly sophisticated products, as dictated by global market requirements. In fact, the U.S. prestige beauty industry reached $17.7 billion in 2017—a 6% percent increase over 2016, according to The NPD Group. At the forefront, the skin care category grew in sales by 9% and contributed 45% of the industry’s total gains.1

In addition, shorter deadlines, more regulations and fewer chemists are all hallmarks of this new world, which has resulted in the need for formulators to adapt and look for new approaches to develop cosmetic products. For several years, we have been proposing an approach called minimally disruptive formulation.This approach makes use of the fact that several types of raw materials, when added to formulations in low concentrations, i.e., 5% or less, can create new aesthetics—a key characteristic of sophisticated products.

These raw materials function at low levels because they are surface-active, lowering the surface tension of aqueous and oil phases, which results in unique aesthetics that delight and astound consumers. The present article reviews some formulating fundamentals to demonstrate how low amounts of these surfactant materials change the characteristics and sensory profiles of basic moisturizing lotion formulas.

Formulating Fundamentals

Several important concepts in product development should be at the forefront of the formulator’s mind when evaluating raw materials.

- Each raw material must have a specific function in each formulation;

- Each raw material in a formulation must be cost-effective;

- Formulators should question whether each raw material is necessary;

- Platform formulas are present within each product to provide specific required elements; and

- Ingredients beyond these platforms are modifiers and provide added desirable properties to products.

Formula Modifiers

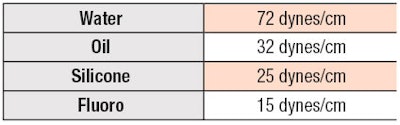

Considering the latter, compounds that act as effective modifiers are surface active silicone-containing polymers. Silicone polymers have low surface tension, i.e., in the range of 20–25 dynes/cm, while fatty materials have a surface tension of 30–32 dynes/cm. Silicones wet the skin well and have a dry, powdery feel. Surface-active agents have at least two different groups linked together chemically that, in pure form, would be insoluble in one another. For example, oil, silicone fluid and water are insoluble in each other (see Figure 1) but when combined in a single molecule, they become surface active and provide aesthetic benefits to formulations.

The salient property of silicone surfactants is that when chosen properly, they have the ability to lower the surface tension of both oil and water phases to levels of around 25 dynes/cm. Surface tension data for the different phases that can comprise a surface-active product are shown in Table 1. Note that the present article describes a method for evaluating the described silicones in test formula environments; since numerous interactions occur between raw materials in a formulation, testing neat additives is of little pertinence to the present discussion.

At 3%, PEG-8 dimethicone provided a more lubricious, smoother and less greasy lotion than the control.

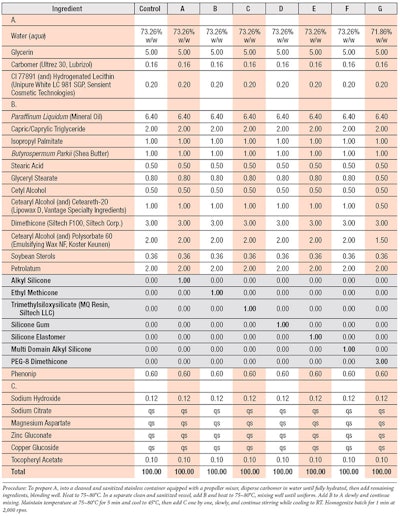

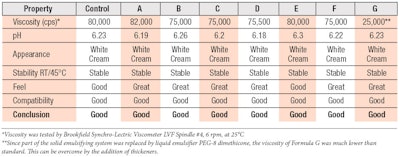

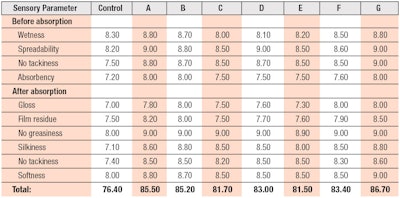

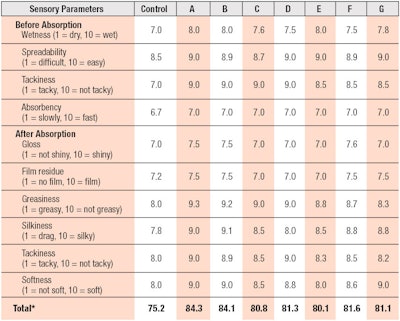

Lowering the surface tension results in formulas with improved spreadability, wetting properties and different aesthetics. Furthermore, following the minimally disruptive formulation model, these properties can be obtained by the addition of levels as low as 1% to either the oil or water phase, or both. To demonstrate, several formulations were developed (see Table 2) and evaluated for parameters such as viscosity/stability, sensory properties and skin feel; see Table 3, Table 4 and Table 5, respectively.

Discussion

Small amounts of various silicone surfactants resulted in several alterations to the base formulation. For example, the partial replacement of solid emulsifiers with the specified PEG-8 dimethicone (Formula G), here at 3%, resulted in a lotion that was more lubricious, smoother and much less greasy than the control. A concentration of 3% was chosen since it is above the critical micelle concentration of a silicone in either oil or water. In contrast, the formula utilizing trimethylsiloxysilicate (Formula C) had a unique powdery, dry feel on the skin; furthermore, it spread better on the skin.

With ethyl methicone (Formula B), spreadability increased, resulting in an improved ease of application. In addition, the product felt smoother and provided a silky feel and bright look to the skin. Alkyl silicone, in turn (Formula A), made the control formulation somewhat thicker but improved the ease of application, resulting in a smooth, soft skin feel.

In the samples incorporating silicone gum (Formula D) and silicone elastomer (Formula E), these formulas were unstable and demonstrated poor aesthetics. Finally, the addition of a multi-domain alkyl silicone (Formula F) made the lotion very soft and glossy on the skin, increasing its playtime and cushion.

Microscopy of the Test Lotions

Microscopy of the test lotions revealed fundamental differences in structure (see Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9). Here, a digital microscope was used to capture images of the control and test products. Images were taken at 100× and 400× at different sites on each microscopy glass slide; software was used to process the images.

As might be expected, the samples with the smallest uniform droplets performed best in terms of stability. These products also spread more uniformly on skin, compared with formulations comprising larger droplets.

Conclusions

As demand for more sophisticated personal care solutions rises, so too will demand for sensory-enhancing ingredients. MarketsandMarkets, for example, valued the global silicone surfactants market at US $142.7 million in 2016, which the group projects will reach $207.5 million by 2022.2 This may be due in part to their maximum effects at minimal quantities; which, in turn, minimally impacts the end cost of formulations.

References

- npd.com/wps/portal/npd/us/news/press-releases/2018/us-prestige-beauty-industry-sales-rise-6-percent-in-2017-reports-the-npd-group/ (Accessed Mar 27, 2018)

- marketsandmarkets.com/Market-Reports/silicone-

surfactant-market-192476281.html?gclid=EAIaIQobChMIkL6t5_KC2gIVwmSGCh0oVQ8aEAAYASAAEgJKWPD_BwE (Accessed Mar 27, 2018)