Competition in the cosmetics market is fierce with companies striving to stand out from the crowd to turn “one-time” customers into dedicated, loyal followers of their brands. In this environment, cosmetic products must offer consumers more than great colors, appealing ads and an attractive appearance—they must create a positive product experience. To achieve these ambitious goals, formulas need to provide additional benefits including superior application properties and optical effects to offer consumers immediate satisfaction.

Functional filler pigments are used in an array of cosmetic products to adjust key sensorial and optical properties and affect the application behavior of color and care formulations including mascara, lipstick, lotions, creams, shower gels, hair gels, eye liner, foundations, soaps, pressed and loose powders, powder-to-cream products and nail lacquers. While color pigments, colorants, dyes and perfumes lend body and character to cosmetics, functional filler pigments fine-tune subtle properties such as viscosity, hardness, pay-off, volume, skin feel, transparency and soft focus effects—which are of decisive importance for the haptic properties of a cosmetic product and thus for consumer acceptance.

Since these functional ingredients do not, as a rule, determine the predominant characteristics of cosmetics like color or odor, they are usually odorless, white powders with pleasant skin feel and good spreading behavior in typical cosmetic media including water, oil, waxes or nail lacquer bases.1 Hence, a vast number of fillers are available, and almost all of them are white powders with a specific skin feel. Up to now, no reliable physical method has been available to characterize the optical properties of functional filler pigments. In addition, haptic tests by panelists are highly subjective.

As a consequence, the suitability of any particular filler for a specific formulation is not made apparent until time-consuming tests have been conducted with many different fillers. This is particularly true for the influence of functional filler pigments on the optical properties of the formulation such as transparency vs. hiding power, whiteness, and matte vs. glossy appearance of the skin. Therefore, an effective pre-selection process would be highly beneficial to screen a large number of functional filler pigments for each specific formulation. This article discusses a new physical method for the characterization of the relevant optical properties of functional filler pigments. The goniometric method described can be used to determine the soft focus factor (SFF) and provide formulators with “at-a-glance” information on the effect of functional filler pigments.

Optical Effects

Functional filler pigments significantly contribute to the optical appearance of creams and foundations on skin by their light scattering and mattifying behavior. Light scattering describes incoming light that is more or less reflected in all directions by the filler particles; this is often referred to as diffuse reflection. High scattering often causes a whitish appearance and the optical hiding of skin, whereas low scattering leads to high transparency both in the formulation and on the skin.

Besides the hiding power versus transparency of a cosmetic product, matte and gloss finishes are also important optical properties influenced by functional filler pigments. A matte effect refers to the oil absorption and subsequent reduction or elimination of undesired gloss on skin. This effect depends on the surface structure of the functional filler particles, which influences the light-scattering behavior. By providing the product surface with a micro texture, the functional filler pigment in turn scatters additional light on the surface, producing a matte appearance.

This leads to a particularly natural look or so-called soft focus effect. The term soft focus is a blurring effect well-known in photography. In this technique contrasts are changed, leading to the deliberate blurring of the complete image or a section of the image. It makes hard lines appear softer and less visible. Cosmetic products containing pigments with diffuse light-scattering properties can create these same effects.

Materials and Methods

In order to objectively quantify the optical properties of functional filler pigments in a standardized manner, a method was developed based on a goniometer—a device that takes reproducible physical measurements from various angles. This instrument can be used to provide key data on the optical behavior of filler materials to allow for an effective pre-selection process. In short, the method involves measuring the brightness, or L* value of the CIE L*a*b* system, of the powder samples embedded in a nitrocellulose film coated on a black draw-down card. While the illumination angle is fixed at 45 degrees relative to the plane of the draw-down card, measurements are taken at various angles across the half sphere, above the measured point on the card (see Figure 1).

The draw-down cards are prepared by blade-coating (blade = 500 μm width) with nitrocellulose lacquer loaded with 2.5% w/w of the functional filler pigment, after which the lacquer film is dried for at least 60 min on a drying plate at approximately 40°C. The obtained reflection pattern of the measurement curves shows the crucial optical properties of the sample in a transparent film. This method is particularly recommended for colorless functional filler pigments since color, described by the a* and b* values of the CIE system, is not covered by the L* value. However, this value is usually sufficient as the materials in question are mostly colorless, white powders.

Results

Example measurement results illustrating the benefits of this evaluation method are as follows. Figure 2 shows the reflection of pure nitrocellulose lacquer. It has high brightness in the specular direction due to the smooth surface of the lacquer. This brightness drops instantly when leaving the specular viewing conditions as the lacquer is very transparent and the dark draw-down card dominates all viewing directions of the specular angle.

Figure 3 shows the goniometric brightness curve over a draw-down card coated with nitrocellulose lacquer loaded with a functional filler pigment that consists of mica obtained from a dynamic drying technologya. This filler consists of thin mica platelets with a smooth and horizontal arrangement in the lacquer film and hardly any disturbance of the lacquer surface. As a result, the surface gloss is maintained. Due to its low refractivity, this particular mica has low covering power in the lacquer and the lacquer remains transparent— similar to the appearance of the pure lacquer without sample loadings. This sample therefore represents a neutral filler with a low impact on the optical properties of formulations.

Figure 4 shows the reflection pattern of another functional filler pigment consisting of titanium dioxide, mica, silica and aluminab. This sample has stronger scattering power than the mica, therefore the L* values are much higher under all angles while there is still a distinct brightness in the specular direction. Due to its scattering properties, this filler can substantially blur irregularities of the skin, such as spots or wrinkles, by diffusing the reflected light. In spite of these scattering properties, however, it still shows a certain amount of gloss within the lacquer film, which is evidenced by the sizeable brightness in the specular direction of the diagram. This characteristic is representative of functional filler pigments that provide “radiance” to a formulation, i.e., a subtle, favorable gloss on skin that is a popular choice for marketing claims substantiation.

Figure 5 shows the reflection pattern of an alternative functional filler pigment consisting of mica and titanium dioxidec. This filler has even stronger scattering power than the aforementioned filler pigmentb; therefore, increased L* values are observed under all angles with this mica and titanium dioxide filler pigment. As a result, it has an almost circular remission curve, which means it diffuses incident light very efficiently in all directions by scattering. In addition, it imparts a matte, velvety surface texture to the film surface.

Broader Implications

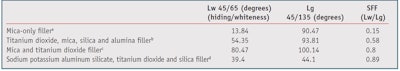

The described measurements open the possibility to quantify three important properties in a single analysis: hiding power, mattifying power and light diffusion capacity. To create a measurable value for these properties as well as for the soft focus effect, two key performance indicators were identified. Termed Lw and Lg, these indicators are extracted from the measurements described above and further illustrated in Table 1 and Figure 6.

Lw refers to the whiteness of the functional filler pigment by light scattering. Highly transparent fillers will have low Lw values, e.g. the mica-only fillera, while hiding fillers have high Lw values, e.g. the mica and titanium dioxide fillerc. Lg describes the brightness of the functional filler pigment measured at the specular angle of 135 degrees. This value describes the degree of gloss provided in the film as shown on the draw-down card. Further, Lw/Lg = the SFF, which describes the gloss minimization of the sample.

Lw/Lg may also be described as the circularity of the goniometric L-curve, and is a clear measure for the overall light diffusing property of the functional filler pigment in all directions. By this definition, the ideal soft focus filler would have a high SFF value, close to 1.0, whereas a less-effective, gloss-supporting filler would exhibit a low SFF of, e.g., 0.2. Values above 0.5 indicate good light-scattering properties.2 Figure 6 shows the Lw and Lg values and SFF of the mica and titanium dioxide fillerc, as an example.

Figure 7 shows the goniometric measurement results along with the calculation of Lw/Lg for a sample functional filler pigment consisting of a spherical sodium potassium aluminum silicate core coated with titanium dioxide and silicad. This functional filler pigment was designed with a lightscattering and porous surface structure to provide a mattifying effect along with a moderate degree of whiteness. Results of this design confirm the filler’s transparency and high SFF. These traits, as noted, are particularly useful for soft focus effects and to reduce undesired gloss.

Formulation Implications

To develop effective products using this method, formulators can first select a functional filler pigment with a high SFF to provide desired soft focus effects. Then using the whiteness value, Lw, of the functional filler pigment, they can choose the right degree of hiding power and whiteness for the formulation. The SFF, Lw and Lg values of functional filler pigments provide tremendous benefits to formulators in that they enable the pre-selection of suitable materials to reduce the number of experiments to trials with a smaller number of functional filler pigments that have already been determined as suitable for the given formulation.

Meeting Modern Trends

How might the formulator apply this method to a product that meets new technology trends? Consider today’s changes in digital broadcasting and recording engineering that have brought about huge shifts in display precision. Modern, high definition (HD) cameras have a significantly higher resolution than ever before, displaying clearer and more realistic images of individuals—including more details of the skin, making the slightest irregularities visible.3 As a result, makeup, along with other special effects, has become more significant and can be developed with this technology mind. In addition, being “ready camera” describes the fact that individuals have their photographs taken more frequently than in previous decades with the use of mobile phone cameras, webcams and other recording devices, which makes looking good at any moment under high resolution conditions more important than before.

The requirements for HD and ready camera makeup differ from traditional products. First, they should have oil-absorbing capacity to deliver a matte finish, and should not be too shimmery or shiny. Second, modern makeup should balance sufficient concealment with the property of looking natural on skin. They also should mask skin impurities and redness and improve the optical impression by instantly reducing fine lines and wrinkles. Last but not least, their light-diffusing properties should make complexions appear flawless under the conditions imposed by HD equipment, as small variations and mistakes are immediately visible.

Further, powder-based products may only be applied sparingly otherwise they can have a chalky or floury appearance; a very matte finish makes skin appear dry and flaky, and the face appear unnatural. On the other hand, anything that is remotely shiny may give an oily appearance and emphasize small wrinkles and skin irregularities. In addition, the textures of foundations are clearly visible under HD conditions. Taken together, all of these conditions call for new formulation and application techniques.

Functional filler pigments can meet these demands for a flawless appearance and natural radiance, and microfine fillers with particle sizes below 20 μm are particularly suitable for this purpose. Thus, while modern trends pose new formulating challenges, the right choice of functional filler pigments enables formulators to develop products for these emerging trends.

HD makeup has already reached the broader cosmetics market thanks to its use by avant-garde makeup artists, and it will continue to influence global trends. Multifunctional blemish balm (BB) creams out of Asia are evidence of such. BB creams gained a noticeable following for their skin-regenerating and care functions, and are now also being used in Asia for their potential to provide natural-looking skin coverage. Modern variants of these products are promoted for their combined benefits as a primer, foundation, moisturizer, physical sunscreen, pore minimizer and skin refiner, with claims such as “skin tone correction” and “wrinkle-hiding” on the product label.4 Functional filler pigments can provide valuable contributions to the functionalities of this product category. Optical effects such as those described are also of interest to support anti-aging claims.

Functional filler pigments are capable of accomplishing immediate anti-wrinkle effects and optical wrinkle reduction, such as where small shadows appear on the face with uneven or flaccid skin or wrinkles. With the help of light-scattering ingredients, these wrinkles can be optically filled and shadows can be reduced; thus the skin appears smoother. Various functional filler pigments are used for this purpose as they are able to compensate for fine irregularities due to their special surface structure.

Conclusions

Combinations of anti-aging ingredients with functional filler pigments can be used to substantiate a broad range of marketing claims to differentiate products by providing immediate sensory reinforcement of skin care benefits; e.g., instant optical effects that convey subtle physiological impressions, which can drive repeated product purchases. In relation, the novel method of determining the SFFs of functional filler pigments described here offers substantial benefits to formulators in their work for modern trends in cosmetics.

References

- Schrader and Domsch, Cosmetology—Theory and practice: Research—Test methods— Analysis—Formulas, Verlag für chemische Industrie, Germany (2005)

- C Schmidt and X Petsitis, Physical characterization method for the optical properties of cosmetic filler powders, SÖFW, 1–2 42–48 (2010)

- The Daily News Online, available at www.enotalone.com/article/19646.html (Accessed Jan 5, 2012)

- BB Cream, available at https://en.wikipedia.org/wiki/BB_cream (Accessed Feb 13, 2012)