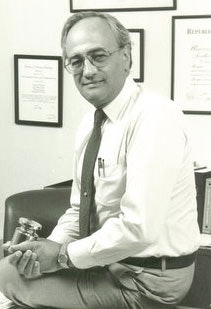

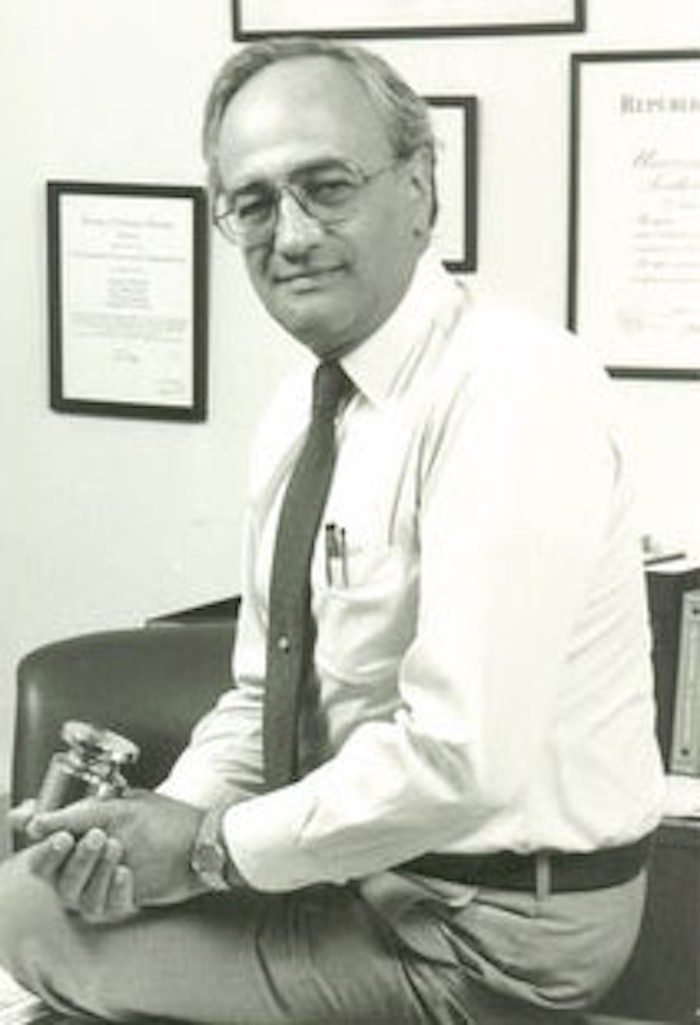

Today, product formulation goes hand in hand with efficacy testing, but nearly 40 years ago, when Sergio Nacht, PhD, started out in the personal care industry, it was a different story. Throughout his decades in personal care, Nacht has developed methodologies that have allowed the personal care industry to establish efficacy of a product and convey this to the consumer. He has also been instrumental in the increased efficacy of personal care products through sustained release.

C&T: What was the first job you had in personal care and what were your responsibilities?

My first job in the personal care industry was in 1973, when I joined Richardson-Vicks Inc. as director of biomedical research. I was responsible for the safety and efficacy testing of skin and hair products, which at that time included the brands Oil of Olay, Clearasil and Pantene. I was also responsible for running clinical trials to help formulators develop efficacious formulations. I developed new methodologies to demonstrate the efficacy, because almost 40 years ago, there were no accepted methodologies. I am one of the founders of the International Society of BioEngineering and Skin, which was formed to develop better methodologies to evaluate efficacy of topical products.

C&T: What methodologies were developed while you were at Richardson-Vicks?

We developed a lot of new methodologies, including one to measure the visco-elastic properties of the skin. This measured the softness and elasticity of the skin to establish the efficacy of moisturizers. Another was to measure the skin friction coefficient. The friction of the skin is the measure of the hydration of the skin and the greasiness of the product. The lower the friction coefficient, the greasier the product is perceived by the consumer. We also published about 30 papers. In 1981, a paper on the skin friction coefficient won a Best Paper Award from the Society of Cosmetic Chemists.

C&T: Was it difficult for you to adjust to the personal care industry?

When I started at Richardson-Vicks, I was a biochemist with experience primarily in academic research. Translating that research into consumer products was a big challenge because there was little research done on consumer products in 1973. We were pioneering in that area, because it was Richardson-Vicks, Unilever, Procter & Gamble and very little else. [Efficacy and safety testing] research grew as a concept when the public became more educated in looking for products that were more efficacious.

C&T: How did efficacy testing come about and how did that impact the product development team?

Until the 1960s and 1970s, people evaluated products from a sensory point of view; they touched, smelled and felt the product. Consumers were not trained to look for efficacy. Then advertisements began to appear on the television that contained efficacy claims such as “softer skin,” “smoother skin” and “less wrinkles.” People even learned to look for ingredients. The industry trained and taught the consumer to look for efficacy and what ingredients to seek. Formulating for feel is important, but there needs to be formulation for efficacy as well. The product has to be superior, or the consumer will not repurchase it. Formulators changed the way they formulate as a response to consumer demands.

C&T: What was the biggest lesson you learned in your first position?

The biggest lesson that I learned is that well-formulated consumer products are efficacious. I came to the industry with the attitude that the personal care industry was selling what Charles Revson called “hope in a jar.” The key is that if hope does not get realized, the consumer will not buy that product again. What moves this industry is a repeat purchase.

C&T: What do you see as a current challenge for the formulator?

The challenge to the formulator today is to utilize novel ingredients that are coming every day, and to discriminate the real from the hype. There is a lot of hype in the industry, but there is a lot of science. The formulator needs to discriminate and learn to maximize the efficacy by formulating with those ingredients adequately to obtain better products.

C&T: What technology that you helped develop are you most proud of?

In 1987, I moved to a company called Advanced Polymer Systems. There, I was co-inventor of a unique technology used in topical care for sustained release called Microspongea. We developed the next generation of retin A, called retin A micro. We also developed the first stable retinol formulation. My experience in testing helped me in the development of this technology, as one of my areas of expertise was measuring the penetration of active ingredients.

C&T: Has the microsponge been used for other technologies?

I worked with Cardinal Health to develop unidose capsules for topical applications using our delivery technology and their gelatin capsule technology (now owned by Catalent). It uses the delivery technology to entrap retinol and peptides in the perfect dosing for an anti-aging effect.

C&T: How did the microsponge technology evolve?

We were trying to develop a novel microencapsulation technique for oils. We ended up with a sponge and realized the enormous potential of that product. In research, you always need a little bit of luck, but you also have to be smart enough to recognize the opportunity.

C&T: Describe the role between the formulator and the testing team?

The formulator, biochemist and marketer are in a marriage, and there has to be communication. If the partners do not communicate, things go bad. The formulator makes a prototypical formulation, which has to be tested for safety and efficacy. If it works, then marketing has to evaluate whether it likes it or not. If the product does not perform, then the biochemist goes back to the formulator to reformulate. Everybody has to be happy with the product.

C&T: What has been one of your biggest challenges in personal care?

The biggest challenge is always communication and developing a good rapport among all the parties involved. Sometimes you have to be the villain if everyone loved the product but it showed to be irritating in safety testing.

C&T: What advice would you give biochemists just starting in the industry?

I would tell them to study the biophysical attributes of the skin and hair. Books are essential, but academic research is a great source. Scientific meetings are also a great source of information.

C&T: What has changed since you began in efficacy testing?

There are more novel and sensitive instruments to measure skin attributes. That is due, in part, to the use of computers, which has helped tremendously. There are very significant improvements in the methodologies and the instrumentation used to measure properties of the skin. Digital photography has been a tremendous bonus to demonstrate before-and-after effects.