Consumers have become increasingly aware of hair damage caused by chemical processes, heat styling and environmental factors. In addition to healthy, shiny, smooth and silky hair, both men and women look for protection against split ends and breakage, along with greater strength and resilience.

Many women believe they have damaged hair, and products that make hair-strengthening claims have caught the attention of these consumers. Silicones hold promise for providing hair-strengthening benefits, especially in products designed for damaged or ethnic hair.

A New Role for Silicones

A variety of silicone materials are recognized for their sensory and functional benefits in hair care products. Initially incorporated into formulations for their conditioning properties, silicones also provide shine,1 aid color retention2 and protect against heat damage3 from curling irons and blow dryers.

In the study described in this article, a method was developed to determine whether silicones could also provide strengthening properties to hair, helping to counteract potentially damaging treatments. In combination with the other multifunctional properties of silicones, hair strengthening would offer additional consumer benefits from individual products.

The hair care industry has responded to these market needs, and a number of commercially available products incorporate organic ingredients traditionally used to strengthen or repair hair. These typically include various wheat, soy or hydrolyzed vegetable proteins. Another conventional ingredient, panthenol, is claimed to provide hair strengthening as well as some degree of conditioning.

Assessing Hair Strength

Hair strength can be evaluated by methods such as tensile testing, fatigue testing, microscopic analyses, light scattering measurements, and simple combing and counting, which involves combing a swatch of hair and physically counting the number of hairs that break.

The hair-strengthening properties of a range of silicones, both functional (e.g., amino, polyether, alkyl) and nonfunctional (e.g., fluids, gum blends, elastomers and resins), were evaluated in dilute form in leave-on and rinse-off applications, and also in a prototype leave-on conditioner. Single-fiber tensile testing was used in this study for several reasons. First, the method is both scientific and quantitative, and it is a recognized measure of hair strength.4–6 In addition, results are not affected by friction resistance; silicones are already known for reducing friction. Finally, in-house expertise already existed for other fiber materials; this expertise was translated to measurements of single hair fibers.

In the single-fiber tensile test, the diameter of hair fibers was measured using a laser micrometera. Using modeling glue, a single unaltered European brown hair fiberbwas mounted to two tabs to create both a control and a treated sample from this one hair fiber (Figure 1). This hair type was selected because it shows the least amount of variability in damage fiber-to-fiber.7

Hair fibers having diameters of 50–80 µm—approximately 65% of the fibers for this hair type—were selected for this study. The control and the treated samples were prepared by placing the mounted fiber into the test solution that was maintained at a constant temperature of 40°C for 2 min to simulate water temperature during bathing. In the case of the control, the solution was deionized water. The section of the fiber (i.e., whether closer to the root or to the tip) was randomized to remove bias from the study.

Three sets of tests were conducted:

•Leave-on application: Dilute silicone material at 2% active level in deionized water (Formula 1).

•Leave-on application: Hair conditioner formulations at 2% active level (Formula 2).

•Rinse-off application: Dilute silicone material at 2% active level in deionized water, followed by rinse. To simulate a rinse-off application, treated samples were placed in an ultrasonic bathcof deionized water at 40°C for an additional 2 min.

Once treated, the control sample and the treated sample were conditioned overnight at a constant relative humidity of 60%. The need to control humidity during testing was based on literature and internal testing, which indicated humidity level was a critical factor in hair strength; higher humidity results in lower hair strength.8 A universal testing machinedwas used to pull test fibers to their breaking point; 50 fibers were tested for each material.

For each fiber, a curve was generated giving the load force vs. the total displacement (sometimes called elongation) traveled for both control and treated samples. Work is the calculated value of total energy or force needed to stretch the fiber multiplied by the displacement, which would be represented by the area under the curve in Figure 2 for a given elongation. Based on information in the literature, analysis was performed on the data at the fixed point of 20% elongation.5–6

Work at 20% for the control was compared to the treated sample (for each of the individual values) using statistical softwaree. Average work for the population was also compared using the same statistical software.

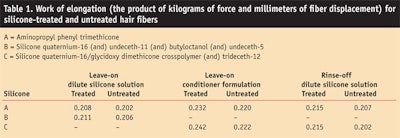

Results showed that three silicones in particular demonstrated hair-strengthening properties:

•Silicone quaternium-16/glycidoxy dimethicone crosspolymer (and) trideceth-12f

•Silicone quaternium-16 (and) undeceth-11 (and) butyloctanol (and) undeceth-5g

•Aminopropyl phenyl trimethiconeh

Hair fibers treated with these silicones required higher average work values at 20% elongation than the control, with a 90% confidence level or greater (Table 1).

The Hair-strengthening Mechanism

To better understand the mechanism for hair strengthening, the authors examined hair fibers using a scanning electron microscope (SEM). Figure 3 shows an untreated hair fiber in which the well-defined cuticles overlap. Also shown is a hair fiber treated with silicone quaternium-16/glycidoxy dimethicone crosspolymer (and) trideceth-12 incorporated into a prototype rinse-off conditioner. Note that the silicone forms a continuous film along the fiber shaft, and hair cuticles are not visible.

Figure 4 illustrates SEM results on a hair fiber treated with aminopropyl phenyl trimethicone, again as a dilute leave-on application. The result is a medium-weight, semicontinuous film along the hair shaft. The SEM also shows a hair fiber treated with dilute silicone quaternium-16 (and) undeceth-11 (and) butyloctanol (and) undeceth-5 in a leave-on application. The silicone leaves a medium-weight film deposited primarily at the open edges of the cuticle.

Two possible mechanisms may explain how a silicone film contributes to hair strength. The film may protect the hair cuticle during elongation, and it may assist in sealing the hair cuticle, helping prevent moisture penetration into and out of the hair cortex, maintaining an optimal moisture level for hair strength. Although the cortex provides the principal strength, it seems likely that the cuticle provides additional protection, including strengthening properties.

Summary

The hair-strengthening properties of these materials, combined with the other functional benefits of silicones for hair care, differentiate silicones from other traditional ingredients promoted for hair strengthening. In addition, silicones offer a range of benefits, including conditioning, color protection, heat protection and shine. When evaluated in specific applications, silicones can allow formulators to develop highly differentiated products that will provide hair-strengthening properties and meet specialized global market needs such as those for damaged hair.

References

1.M Starch, Screening silicones for hair luster, Cosmet Toil 114(11) 55–58 (1999)

2.B Moss, V Ungvary, S Marchioretto and B Johnson, Silicones combine color retention for hair and new spray opportunities, Dow Corning White Paper 27-1171-01 (2005)

3.A Gomes and S Aguiar, Silicones protect thermally-treated hair by preventing moisture loss, Dow Corning Advertorial 27-1124-01 (2005)

4.T Scharfeld, C D’Arrigo and KH Lim, A single hair fiber tensile tester for operation under a scanning electron microscope, Massachusetts Institute of Technology, (http://scholar.google.com/scholar?hl=en&lr=&q=cache:a5TEzkf9tc0J:web.mit.edu/tas/www/HairStretch/HairTensileTest.pdf+single+hair+fiber+tensile+tester+for+operation+under+a+scanning+electron+microscope, (Accessed Jan 18, 2007). See also J Woodruff, Improving hair strength, Cosmet Toil 117(3) 33–36 (2002)

5.AN Syed and H Ayoub, Correlating porosity and tensile strength of chemically modified hair, Cosmet Toil 117(11) 57–64 (2002)

6.AN Syed, H Ayoub and A Kuhajda, Recent advances in treating excessively curly hair, Cosmet Toil 113(9) 47–56 (1998)

7.JA Swift, PC Surinder, DL Coulson and NI Challoner, Flexabrasion: A method for evaluating hair strength, Cosmet Toil 116(12) 53–60 (2001)

8.CR Robbins, The physical and cosmetic behavior of hair, In: Chemical and Physical Behavior of Human Hair, 3rd edition, Chapter 8, New York: Springer-Verlag (1994) pp 300–309